Automatic Reagent Tube Filling Capping and Labeling Machine

An Automatic Reagent Tube Filling, Capping, and Labeling Machine is a specialized piece of equipment designed for the pharmaceutical, biotechnology, or chemical industries to automate the process of filling reagent tubes, capping them securely, and applying labels. This automation helps improve efficiency, accuracy, and overall productivity in laboratory or production settings.

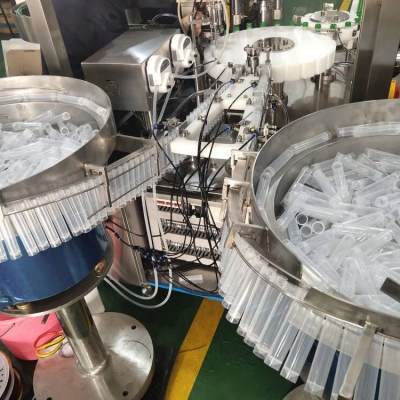

SGXZ80 Double Needle Filling Integrated Machine

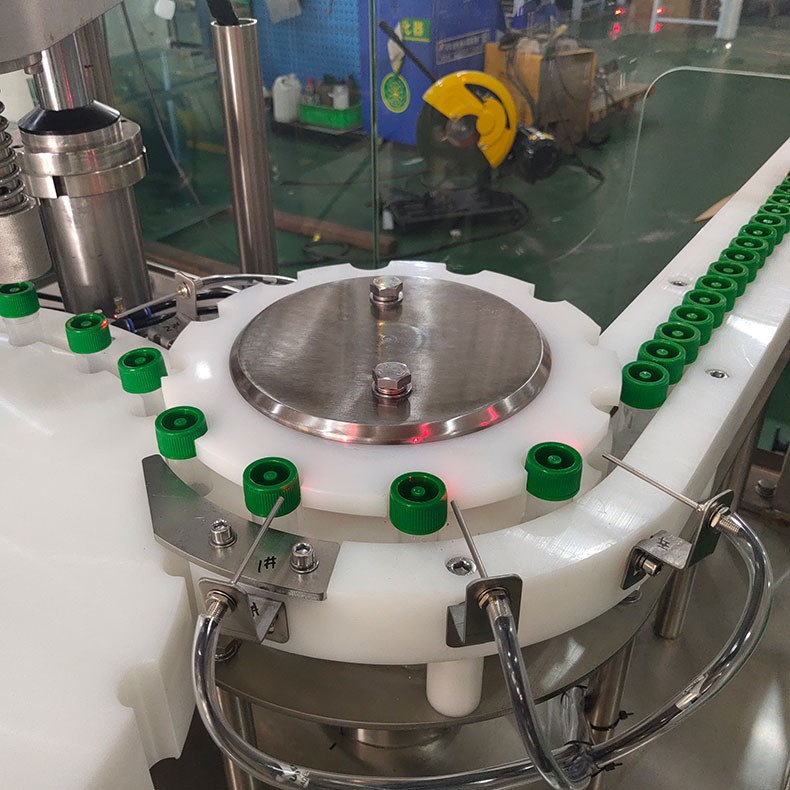

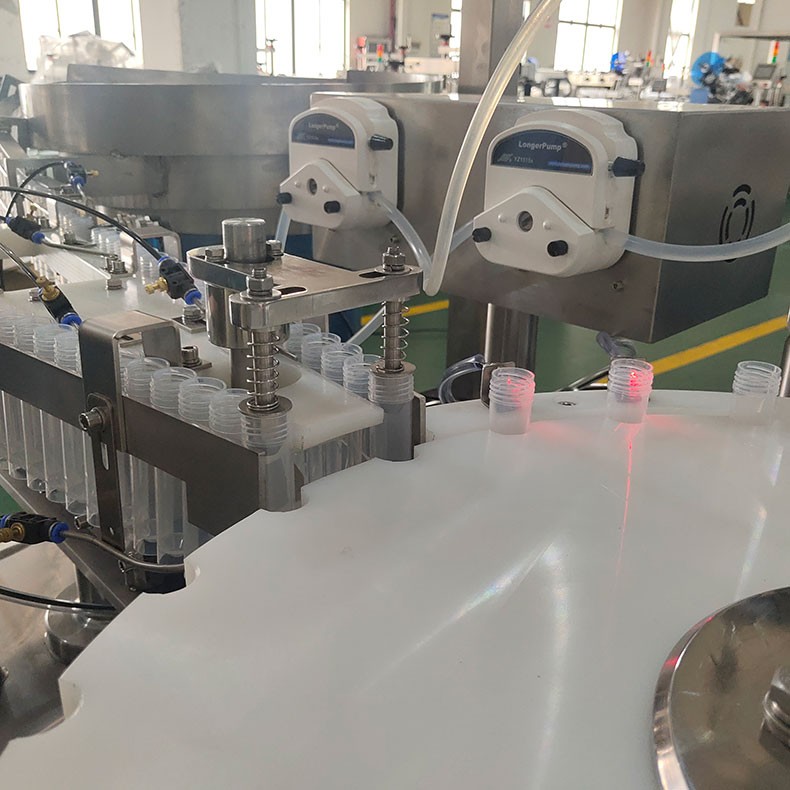

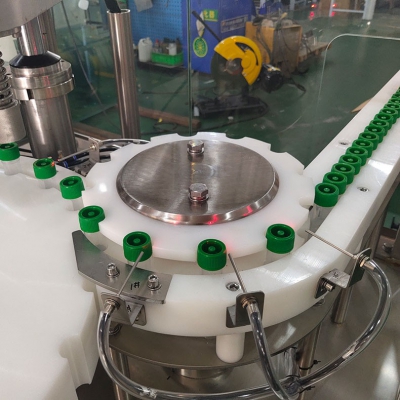

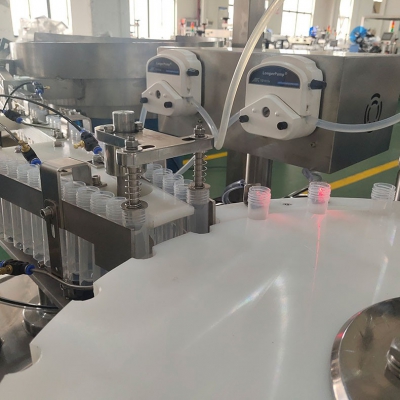

SGXZ80 double-needle filling integrated machine is a fully automatic filling and capping equipment that our company has absorbed advanced experience in similar equipment and has been continuously improved over the years. The whole machine can automatically complete the processes of bottle unscrambling, bottle feeding, quantitative filling, cap arranging, capping, and bottle discharging. Its advanced structural design and high-standard electrical configuration ensure the stable and reliable operation of the whole machine.

After the bottles are sorted by the oscillator, they are sent to the machine, and then the bottles move intermittently with the aliquoting plate. Firstly, the filling process is completed at the filling part; then to complete the cap adding and screwing process; The bottles are delivered to the bottle-out track after passing aliquoting plate and sent out of the machine to enter the next process.

The machine integrates mechanical, pneumatic and automation technology, and has the characteristics of high degree of automation, high yield, wide application and great stability; It is suitable for filling round bottles or special-shaped bottles made of plastic and glass in the pharmaceutical, food, chemical, cosmetic and other industries; It meets the requirements of GMP standards.

The parts in contact with the drug are made of 316L stainless steel or silicone material, and the other exposed parts are austenitic stainless steel.

It can be used alone or in line with other equipment.

Technical Parameter

| Applicable bottle | 2ml-30ml |

| Filling pump | peristaltic pump |

| Filling speed | 60-80pcs/min |

| Filling accuracy | ≤±1% |

| capping accuracy | ≥99% |

| Weight | 650kg |

| Voltage | AC380V |

| Frequency | 50HZ/60HZ |

| Power | 2.5KW |

| Dimension | 2600mm*2200mm*1850mm |

Structure & Performance Characteristics

The equipment is composed of linear oscillation bottle feeding, filling mechanism, electromagnetic oscillation group, capping mechanism, adjustable torque capping mechanism, bottle output mechanism, main transmission system, electronic control system, etc.

1. The whole machine adopts PLC, frequency conversion speed regulation and AC servo control to ensure that when the machine works at different speeds, the coordination and balance between the moving parts are achieved.

2. Intermittent filling on the bottle control plate, the filling head is operated by an eccentric cam, insert the needle tube into the bottle for filling, and lift while filling to reduce droplets, ensuring that the liquid has no impact and splashing, and there is no dripping outside the bottle.

3.This machine is provided with a high-precision cam indexing mechanism to provide an indexing and dividing plate, which can accurately locate the work of each station; The nylon aliquoting plate is made of high-quality polyoxymethylene material, which has good toughness, anti-cracking and no deformation.

4. Using the peristaltic pump filling method, the hose does not have a chemical reaction with the drug, and no particles are produced during operation, which prevents the pollution to the drug by the particles. The filling volume adjustment is adjusted on the control screen, which can be set without stopping the machine, it is convenient for adjustment and accurate in filling volume.

5. The caps are automatically arranged and conveyed by the oscillator, and placing caps is accurate and stable. The special structure design is adopted to ensure that the product can not be filled or capped if there is no bottle during high-speed operation.

6. The capping mechanism, whose lifting is controlled by a cam, the capping head seat has a simple and detachable structure, and is easy to adjust to the center. The capping head part is equipped with an overload protection device. When the cap is tightened to a certain torque, the capping head starts to stop rotating to protect the cap from damage. After the capping is completed, the bottles can be sent to the conveyor belt to the connection line or to the collection tray.

7. Capping head adjustment, before the machine leaves the factory, the capping mechanism has been adjusted accurately and runs stably, and generally does not need to be adjusted anymore. If it needs to be adjusted: adjust the torque parameters on the touch screen, the larger the number is, the greater the torque is.

8. Electric eye monitoring is used to detect crooked and loose caps and will stop the machine when necessary. Because the products with crooked and loose caps are higher than standard products, when unqualified products pass the detection station, it will be detected by the optical fiber, and then the machine will be controlled by PLC to stop.

9. Electric eye monitoring is used to detect and will stop the machine when the cap falls off. Because the product without cap is lower than the standard product, when the unqualified product passes the detection station, it will be detected by the optical fiber, and then the machine will be controlled by PLC to stop.

10. The machine will stop while doors open, when the front glass door is open, the PLC controls the main motor to stop running to ensure safe production.

Main device configuration table

| Serial Number | Product Name | Brand & Place of Origin |

| 1 | touch screen | Weinview (Taiwan) |

| 2 | PLC | Mitsubishi (Japan) |

| 3 | filling motor | Langer |

| 4 | filling peristaltic pump | Langer |

| 5 | main motor | WNM |

| 6 | Capping Servo Motor | Mitsubishi (Japan) |

| 7 | gas cylinder | AirTAC (Taiwan) |

| 8 | electromagnetic valve | AirTAC (Taiwan) |

| 9 | Bottle inspection photoelectric | Panasonic (Japan) |

| 10 | relay | Delixi |

| 11 | breaker | Delixi |

| 12 | power switch | Delixi |

Note: The model specifications of the listed products can be adjusted according to user needs and actual conditions during design.

SFW101 Horizontal Labeling Machine

This equipment can meet customer's requirements for GMP, safety, health and environment in the process of labeling, and mainly complete the auto-attach function of the product. The equipment uses German Siemens PLC and Siemens servo motor. It has the advantages of high speed, high precision, high stability, durability, and flexible use, which can greatly improve production efficiency and save costs. Our labeling machines are mainly suitable for the circumferential (circular label) labeling on various production lines of daily chemical, pharmaceutical, agrochemical, health care products, food, chemical, electrical and other industries. The machine adopts photoelectric detection, touch screen controlled (frequency conversion speed), it has the advantages of accurate labeling and high precision. At the same time, it has the functions of skip labeling without objects, and there is no need to move the label to adjust. The adjustment can be fulfilled by the electronic eye touch screen, which includes such advantages as saving manual adjustment time and automatic detection, etc.

Product Features

1. Program controlled operating system, automatic bottle drop, detection and labeling, batch number printing, prompting and other functions. The coding machine is optional.

2. The anti-slip and deviation design of the traction label feeder mechanism ensures the labeling accuracy.

3. It is suitable for cylinder full body labeling, product outer package and higher position labeling, such as oral liquid bottles, vials, injection bottles, etc.

Technical Parameters

| Model | SFW101 |

| Labeling Speed | 4500 pcs/hr(Defined as related to material and label size) |

| Labeling Accuracy | ±1mm(Do not include material and label errors) |

| Applicable labels | L10-80mm, H10-100ml |

| Applicable product range | diameter 15-25mm(Can be customized according to product) |

| outer diameter of label disc | Disc diameter 300mm, Disc hole 76mm, height 100mm |

| Voltage | 220V—50/60HZ |

| Power | 280W |

| Dimension | 1950X760X1470 mm |

| Weight | 280Kg |

Shanghai Shengsen Packing Machine Co., Ltd is a high-tech company which is specilized in automatic packing machine system. Our company always adheres to "integrity, innovation, communication" as the corporate philosophy, and "technology and service" as the group spirit. We have a complete system of design, installation, commission, training, and maintenance.

Service included: pharmaceutical equipment system, food equipment system, chemical equipment system, electronic equipment system and so on, also we would establish files for all the customers and a maintenance department to solve the problems immediately.

Our company has build a good stable partnership with many famous companies at home and abroad. We have strong advantages of human resources, technology and brand. With a vibrant and versatile group, our company has strong construction and technical power to provide you with the most professional technology and service.

Our company has 20 years of experience in the production of packaging equipment, mainly engaged in labeling machine, filling machine, bottle management machine, aluminum foil sealing machine, and automatic liquid production line and so on. We have professional design team, processing team, and after-sales service team, leading equipment innovation and manufacturing, with the industry-leading technology research and development system.

All the main parts of the machine are processed by our factory and advanced CNC processing equipment, which greatly improves the work efficiency and the precision of parts processing, realizing fully automatic production.

Standardized process management and strict quality inspection system ensure the high quality of production equipment. We also have professional foreign trade team to provide customers with more comprehensive product solutions.

Our company always follow three basic principles: "satisfaction of products quality, satisfaction of advanced technology, satisfaction of after-sale service". We continuously strengthen the comprehensive competitiveness of enterprise and our company keeps developing through competitions and challenges. Our company will provide you the best machine, also with the most advanced technology and the perfect after-sale service. We sincerely hope we can work hand in hand to create brilliant.

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: What certificates you can provide?

A: Our factory provide the CE,SGS,ISO,and according to some countries,we also can provide the PVOC, COC,SONCAP...etc.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can i know the machinery quality before i order?

A: First,we will invite you visiting our factory to check the machines quality,and show the machines running for you in our factory.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: Are all machinery your factory made?

A: Our factory make the water purification and filling packing plants.we do not make the bottle making machinery,we have good quality bottle making machinery partner,and we provide to customer same long warranty time and good after service.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: Can your factory provide he whole plant from A to Z?

A: Yes, we can provide the complete plant, from bottling making plant,water purification plant,to filling packing plant.

Q: How can I pay my order?

A: We accept T/T, Western Union paying methods. For those orders less than 500USD, we accept PayPal to pay.

-

6-Pin Ampoule Filling and Sealing Machine

6-Pin Ampoule Filling and Sealing Machine

-

SFW-300 High Speed Horizontal Labeling Machine

SFW-300 High Speed Horizontal Labeling Machine

-

SXGJ130 High-speed Cap Rubbing Machine

SXGJ130 High-speed Cap Rubbing Machine

-

SFS120 Double Sided Labeling Machine

SFS120 Double Sided Labeling Machine

-

8-Pin Ampoule Filling and Sealing Machine

8-Pin Ampoule Filling and Sealing Machine

-

SFW101 Horizontal Labeling Machine

SFW101 Horizontal Labeling Machine

-

Bottle Drying Oven

Bottle Drying Oven

-

Full Automatic Desktop Round Bottle Labeling Machine

Full Automatic Desktop Round Bottle Labeling Machine

-

Semi-automatic Round Bottle Labeling Machine

Semi-automatic Round Bottle Labeling Machine

-

Screen Printing Machine

Screen Printing Machine

-

STJ100 Liquid Filling Production Line

STJ100 Liquid Filling Production Line

-

Dropper Bottle Filling and Capping Machine

Dropper Bottle Filling and Capping Machine

Shengsen has 20 years of experience in the production of packaging equipment, mainly engaged in labeling machine, filling machine, bottle management machine, aluminum foil sealing machine, and automatic liquid production line and so on. We have professional design team, processing team, and after-sales service team, leading equipment innovation and manufacturing, with the industry-leading technology research and development system.

Add.: Room 616, No.28, Moyu Rd, Anting Town, Jiading District, Shanghai, China