Closed Loop Wire Electrical Discharge Machining, KD Series

Features

1. The closed loop wire electrical discharge machining adopts KDXP integrated software, WINDOWS XP platform and embedded control system, which achieves seams connectivity between many types of design software.

2. Castings of the machine tool are made using advanced resin sand casting technique and subject to high-temperature annealing treatment twice, which contributes to the consistent precision of the equipment.

3. The processing head with special wire guide mechanism, the optimum surface roughness Ra≤1.2um.

4. The strong network functions of the XP system make it possible to realize data exchange and remote control.

5. The moving parts of the machine tool use precision ball screw, linear guide rails.

6. The wire rack is C-shape vertical lift structure. The tension of molybdenum wire is uniform.

7. The system with pitch compensation function helps effectively improve the positioning accuracy of the machine tool.

8. Imported hand control system, rapid displacement 3000mm/min.

9. The cooling system adopts a large-capacity water tank, efficient three-layer filter.

10. High capacity database enables users to easily find and conveniently store useful data.

11. The inverter realizes the variable speed control of the movements of wire.

12. The closed loop control adopts a grating system.

13. The closed loop wire electrical discharge machining adopts a centralized lubrication system.

Specifications of the Closed Loop Wire Electrical Discharge Machining

Item | Unit | KD3240CL | KD4050CL | |

Table travel | mm | 320×400 | 400×500 | |

Table size | mm | 435×650 | 520×800 | |

Max. cutting thickness | mm | 260 | 260 | |

Max. cutting taper (optional) | mm | 3degrees/80 | 3degrees /80 | |

Machining precision | octagonal | mm | 0.015 | 0.015 |

taper | mm | 0.03 | 0.03 | |

Max. cutting speed | mm2/min | 180 | 180 | |

Roughness | um | ≤1.2 | ≤1.2 | |

Molybdenum wire range | mm | 0.14-0.2 | 0.14-0.2 | |

Max. operating current | A | 7 | 7 | |

Rated power | KW | <2 | <2 | |

Voltage | V/Hz | 380/50 | 380/50 | |

Max. loading capacity | kg | 300 | 400 | |

Weight | kg | 2600 | 3000 | |

Outline dimensions | mm | 1600×1160×2000 | 1900×1460×2000 | |

Superior Configuration

01. low speed walk wire electrical discharge machining | 02. resin sand HT250 casting | 03. Taiwan HIWIN or PMI linear guide | 04. P3 ball screw | 05. automatic oiling device |

06. main shaft featuring automatic lifting | 07. special wire stabilizing device | 08. two axis grating scale (optional) | 09. special ruby nozzle (optional) | 10. 15-inch LCD color monitor |

11. dual core computer | 12. Taiwan inverter | 13. integrated software system | 14. water tank(doesn’t need to change water for a long period) | 15. USB data exchange |

Longhua is a professional closed loop wire electrical discharge machining manufacturer and supplier in China. We dedicate ourselves to providing our clients with beer pump steel cylinder, car tire inflator, piping cleaning steel cylinder, Ar, CO2 steel bottle, and soda steel cylinder.

Links:https://www.globefindpro.com/products/100281.html

-

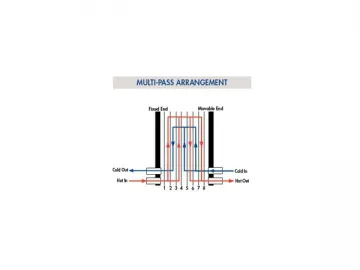

Frame of Plate Heat Exchanger

Frame of Plate Heat Exchanger

-

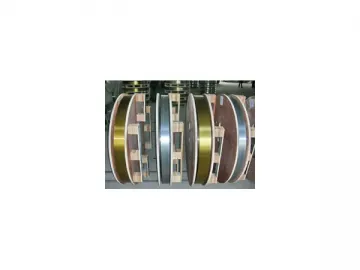

Wire Band

Wire Band

-

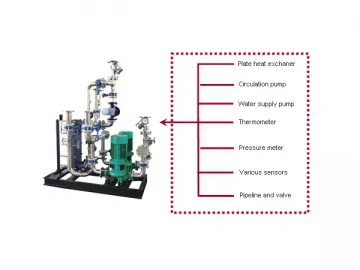

Main Structure Components

Main Structure Components

-

Pneumatic Line Thrower / Steel Cylinder

Pneumatic Line Thrower / Steel Cylinder

-

Tracker Staples 22 GA-XC

Tracker Staples 22 GA-XC

-

Brad Nails 18 GA

Brad Nails 18 GA

-

Beer Pump Steel Cylinder

Beer Pump Steel Cylinder

-

Carton Closing Staples 35 Series

Carton Closing Staples 35 Series

-

Fine Wire Staple 22 GA-1 Series

Fine Wire Staple 22 GA-1 Series

-

Fine Wire Staple 21 GA-3 Series

Fine Wire Staple 21 GA-3 Series

-

Wire Welded Coil Roofing Nails-15 Degree

Wire Welded Coil Roofing Nails-15 Degree

-

Plate Heat Exchanger

Plate Heat Exchanger