Slip Ring Motor

General introduction on medium sized slip ring motors, H355-630

H355-630 AC slip ring motors adopts IMB3 feet mounting type and are of horizontal construction. In the meantime, this AC motor is rated for S1 continuous operation.

In general, this slip ring motor is designed with three enclosure protection levels, namely, IP23, IP44, and IP54. The cooling method of our slip ring asynchronous motor falls into four types, that is, IC01, IC81W, IC611 and IC616.

Structure introduction on slip ring AC motors

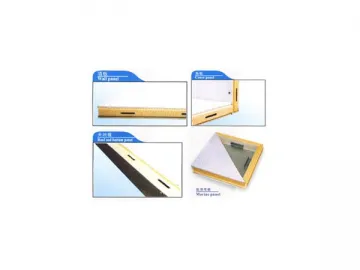

1. The boxed-type steel plate welded motor base is adopted to reduce the motor frame weight and increase the frame rigidity. This design also makes our slip ring motors easy to install and maintain.

2. We employ low loss and high strength round silicon steel plates as the raw material and adopt highly advanced punching technology, to produce the stator and rotor. Thus, the iron loss is greatly reduced and the efficiency of our slip ring motor is largely improved.

3. Both the rotor and stator of our slip ring asynchronous AC motor are of F class insulation. Wire inserting for stators can be finished outside the stator frame. The stator coil is a double layer formed coil which features good rigidity, and the inserted windings of the stator are processed with VPI solventless varnish.

4. The rotor core is shrunk onto the shaft and the rotor coil is tightly inserted into rotor core slots. Advanced brazing techniques are adopted for connecting rotor coils, which ensures the high mechanical strength and good conductivity at the brazed joints.

The rotor coil ends are banding fixed. After the rotor winding is vacuum pressure impregnated, the winding is connected to the slip ring unit. This rotor design provides the rotor with excellent performance against centrifugal forces.

5. For convenient maintenance and repair, the slip ring of this AC slip ring motor is mounted outside of the motor frame and at the non-drive end. Meanwhile, this slip ring design also shortens the distance between bearings, reduces the motor vibration, saves installation space and avoids the production of carbon dust due to carbon brush wearing, and more. Within the slip ring chamber, there is a cooling fan, and a filter for collecting carbon dusts.

6. Designed in standard rolling bearing structure, this slip ring motor can employ either grease lubrication or oil lubrication. If sliding bearing construction is desired, the lubrication methods can be oil ring lubrication, forced lubrication, or combinational lubrication.

Parameters of three phase, asynchronous slip ring motors

Motor model | WTYR, WTKS, WTKK |

Seat No. | H355 - H1120 |

Power | 220 - 11200KW |

Pole number | 2-24 |

Voltage | 600-13800V |

Frequency | 50HZ, 60HZ |

Protection level | IP23, IP44, IP54, IP55 |

Cooling method | IC01, IC06, IC611, IC616, IC81W, IC86W |

We are an ISO9001:2000 certified slip ring motor manufacturer and supplier based in China, founded in 1981. In addition to slip ring AC motors, we can also produce DC motors, synchronous motors, and mine elevator motors, and more. All our products are CE and BV certified. If you are looking any type of electric machine, please feel free to contact us.

Links:https://www.globefindpro.com/products/100906.html