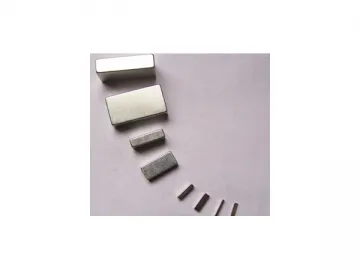

NdFeB magnet

NdFeB magnet BM6

Material Trademark:

N35--N50, 33M--48M, 30H--45H, 27SH--45SH, 25UH--40UH, 23EH--38EH

All trademarks are available.

Working temperature: 80-200 (℃)

Product Feature:

High anti- degausser

Very hard and friable

very stable at atmospheric temperature

Not suitable for use in high-temperature environments

High performance / low cost

If there is no coverage outside of class or electroplating, materials will easy to be corrosion

Products introduction:

NdFeB permanent magnet is mainly used in micro-motor, electronic industry, car industry, petrochemical, NMR devices, sound equipments, maglev system, magnetic drive and magnetotherapy system, and its also used in motorbikes, car oil-duct' s magnetization, with the aim of saving oil.

Earth permanent magnet (NdFeB) has the strongest magnetism nowadays. It does not only has high remanence, high coercivity, high energy product, and high-functional, but also it can processed into a variety of sizes easily. Now, it is widely used in navigation, spaceflight, electron, electrical sound, electrical machinery, apparatus, meters, medical technology, and especially apply to develop high-performance, small and light replacements.

Our factory produces various complex shapes, gradients / profile, and small size, high accuracy permanent magnet. All processing equipments are available. We produce square pole form, round and sphericity general products, and we can also produce abnormity products and process micro-magnets.

Surface treatment:

Type | Information |

Metal | Zinc, nickel, silver, gold |

Organic | Epoxy resin spraying , epoxy resin nickel spraying |

Transiency | Surface passivation |

Size tolerance:

Ring | External diameter | Inside diameter | Thickness | Round | Diameter | Thickness |

Maximum | 100.00mm | 80.00mm | 30.00mm | Maximum | 50.00mm | 20.00mm |

Minimum | 2.6mm | 1.80mm | 0.50mm | Minimum | 1.20mm | 0.50mm |

Tolerance | /-0.1mm | /-0.1mm | /-0.1mm | Tolerance | /-0.1mm | /-0.1mm |

Diamond | Length | Width | Thickness | |||

Maximum | 80.00mm | 80.00mm | 30.00mm | |||

Minimum | 2.00mm | 1.50mm | 0.50mm | |||

Tolerance | /-0.1mm | /-0.1mm | /-0.1mm | |||

Links:https://www.globefindpro.com/products/100935.html