E551T1-B2, E81T1-B2 Flux Core Welding Wire

E551T1-B2, E81T1-B2 Flux Core Welding Wire

Application ofE551T1-B2, E81T1-B2 Flux Core Welding Wire:

With the features of stable arc, less spatter, easy slag off and beautifulwelding seam, this titanium slag heat of CO2 gas shielded flux-cored wire is popularlyapplicable for all-position welding.

Standard-compliant:

GB/T: E551T1-B2

AWS: E81T1-B2

TechnicalParameters of E551T1-B2, E81T1-B2 Flux Core Welding Wire:

| Packaging | Wire Size | Spool Size | Net Weight | ||||

| Φ1.0~1.6(mm) | D100mm D200mm D270mm D300mm K300mm | 1kg, 5kg, 15kg, 18kg, 20kg | |||||

| Chemical Composition of Welding Wire (%) | C | Mn | Si | P | S | Cr | Mo |

| ≤0.12 | ≤1.25 | ≤0.80 | ≤0.02 | ≤0.025 | 1-1.5 | 0.4-0.65 | |

| Mechanical Properties or Deposited Metal | Yield Strengthσ0.2(Mpa) | Tensile Strength σb(Mpa) | Elongation δ5(%) | AKV Impact(J) | |||

| ≥470 | 550-690 | ≥19 | ≥27 | ||||

| Wire Size(mm) | φ1.2 | φ1.4 | φ1.6 | Welding Position | |||

| Welding Current(A) | 120~300 | 160~400 | 190~450 | ||||

| Note | 1. Welding wire should be stocked in dry environment. Open the packs just when welding, so as to avoid the wire rust. 2. Before welding please clean out the oil, rust, water etc from the welding surface; 3.Adopting CO2 gas shielding welding, and gas purity of CO2 is 99.98%. 4. The flow of gas CO2 should be controlled in the range of 20-25L/min during the welding process; 5.The extend length of the welding wire should be controlled in the range of 15-25mm. 6.Preheating before welding to 150-300 ℃, PWHT 700-740 ℃ tempered.  | ||||||

Links:https://www.globefindpro.com/products/101187.html

-

S311, ER4043 Aluminum Welding Wire

S311, ER4043 Aluminum Welding Wire

-

S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

-

ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

-

S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

-

Anti-corrosive Aluminium Sheet

Anti-corrosive Aluminium Sheet

-

Radiator Aluminium Sheet

Radiator Aluminium Sheet

-

E500T-1, E70T-1 Flux Core Welding Wire

E500T-1, E70T-1 Flux Core Welding Wire

-

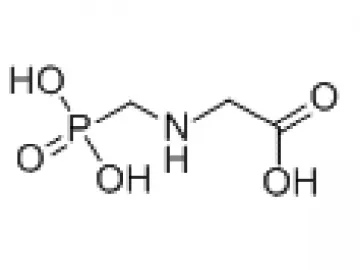

Glyphosate

Glyphosate

-

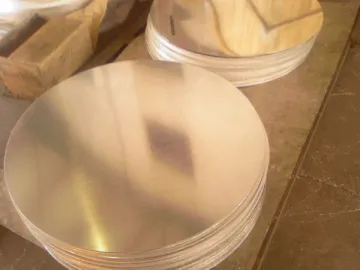

Aluminium Circle for Aluminium Pot

Aluminium Circle for Aluminium Pot

-

Aluminium Disc for Aluminium Cone

Aluminium Disc for Aluminium Cone

-

Irregular Aluminium Sheet

Irregular Aluminium Sheet

-

Aluminium Circle for Aluminium Electric Pan

Aluminium Circle for Aluminium Electric Pan