S311, ER4043 Aluminum Welding Wire

S311, ER4043 Aluminum Welding Wire

Description ofS311, ER4043 Aluminum Welding Wire:

-- As the filling the metal for ALSi1 alloy;

-- Commonly used for MIG or TIG welding for spools or vertical incision;

-- It is grey white after anodizing treatment;

-- Melting point: 1065-1170°F

-- Min. tensile strength: 186 MP.

TechnicalParameters of S311, ER4043 Aluminum Welding Wire:

| Chemical Composition of Welding Wire (%) | |||||||||||||

| Type | Brand | GB | AWS | Properties and Application | |||||||||

| Chemical Composition (%) | |||||||||||||

| TIG | MIG | Cu | Si | Fe | Mn | Mg | Cr | Zn | Ti | Al | |||

| Aluminum Alloy | YH-311 | S311 | ER4043 | ---Good corrosion resistance ability and commonality; ---Used for aluminum alloy gas welding or TIG welding, especially for welding 4043 material; ---Not suitable for welding high-magnesium alloy. | |||||||||

| ≤0.30 | 4.5~6.0 | ≤0.80 | ≤0.05 | ≤0.05 | - | ≤0.10 | ≤0.20 | Rem | |||||

Links:https://www.globefindpro.com/products/101188.html

-

S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

-

ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

-

S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

-

Anti-corrosive Aluminium Sheet

Anti-corrosive Aluminium Sheet

-

Radiator Aluminium Sheet

Radiator Aluminium Sheet

-

Standard Traffic Sign Aluminium Sheet

Standard Traffic Sign Aluminium Sheet

-

E551T1-B2, E81T1-B2 Flux Core Welding Wire

E551T1-B2, E81T1-B2 Flux Core Welding Wire

-

E500T-1, E70T-1 Flux Core Welding Wire

E500T-1, E70T-1 Flux Core Welding Wire

-

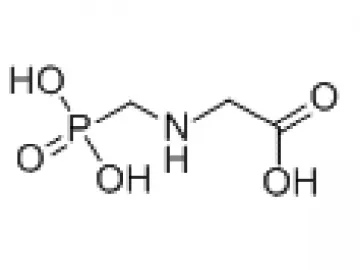

Glyphosate

Glyphosate

-

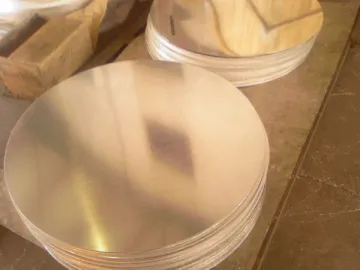

Aluminium Circle for Aluminium Pot

Aluminium Circle for Aluminium Pot

-

Aluminium Disc for Aluminium Cone

Aluminium Disc for Aluminium Cone

-

Irregular Aluminium Sheet

Irregular Aluminium Sheet