ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

Application ofER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire:

-- Used for welding 25%Cr-20%Ni steel;

-- Especially suitable for various of metal welding, as well as the welding ofhigh hardness alloy steel and high carbon steel;

-- Used for welding dissimilar components, heating furnace parts;

-- For welding the gas system components with the temperature below 950 ℃;

-- Its oxidation resistance temperature is up to 1035℃.

Standard-compliant:

| AWS: ER310 | YB/T: H1Cr26Ni21 | JIS: Y310 |

TechnicalParameters of ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire:

| Wire Type | Wire Size | Spool Size | Net Weight | ||||||

| MIG Wire | φ0.8~1.6(mm) | D100mm D200mm D300mm D270mm | 1kg 5kg 15kg 20kg | ||||||

| TIG Wire | φ1.6~5.0(mm) | Straight wire length: 1 meter | 5kg 10kg | ||||||

|

| Chemical Composition of Welding Wire (%) | ||||||||

| Type | Mechanical Properties or Deposited Metal | C | Si | Mn | Cr | Ni | Mo | Other | |

| Tensile Strength σb(Mpa) | Elongation δ5 (%) | ||||||||

| ER310 | 607 | 41 | 0.086 | 0.40 | 2.01 | 27.40 | 21.80 | - | - |

| Note | Welding Position | ||||||||

| Welding wire should be stocked in dry environment. Open the packs just when welding to avoid the wire rust. | |||||||||

| Before welding, please clean out the oil, rust, water etc from the welding surface. | |||||||||

Links:https://www.globefindpro.com/products/101191.html

-

S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

-

Anti-corrosive Aluminium Sheet

Anti-corrosive Aluminium Sheet

-

Radiator Aluminium Sheet

Radiator Aluminium Sheet

-

Standard Traffic Sign Aluminium Sheet

Standard Traffic Sign Aluminium Sheet

-

ER50-4, A18, ER70S-4, YGW12 Mild Steel Welding Wire

ER50-4, A18, ER70S-4, YGW12 Mild Steel Welding Wire

-

Square Aluminium Sheet

Square Aluminium Sheet

-

S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

-

S311, ER4043 Aluminum Welding Wire

S311, ER4043 Aluminum Welding Wire

-

E551T1-B2, E81T1-B2 Flux Core Welding Wire

E551T1-B2, E81T1-B2 Flux Core Welding Wire

-

E500T-1, E70T-1 Flux Core Welding Wire

E500T-1, E70T-1 Flux Core Welding Wire

-

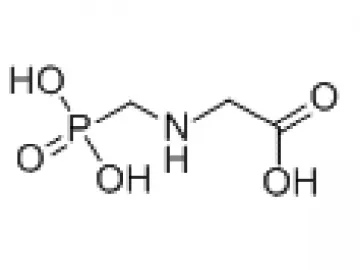

Glyphosate

Glyphosate

-

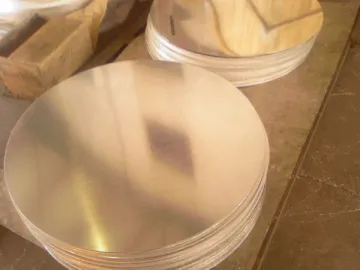

Aluminium Circle for Aluminium Pot

Aluminium Circle for Aluminium Pot