S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

Description ofER5183 Aluminum Welding Wire:

This important welding supplies often works as the filling the metal forALMg4.5Mn alloy, and it contains the following components: 4.3-5.0% Mg,0.5-1.0%Mn and appropriate amount of Cr and Ti.

-- Commonly used for MIG or TIG welding for spools or vertical incision.

-- It is white after anodizing treatment;

-- Melting point: 1075-1180°F;

-- Tensile strength of the welding seam: 294 MP.

Applicationof S331, ER5183 Aluminum Welding Wire:

This key welding supplies is popularly used for welding shipping, drillingequipment, vehicles, storage tanks and pressure vessels, etc.

TechnicalParameters of S331, ER5183 Aluminum Welding Wire:

| Type | Brand | GB | AWS | Properties and Application | |||||||||

| Chemical Composition (%) | |||||||||||||

| TIG | MIG | Cu | Si | Fe | Mn | Mg | Cr | Zn | Ti | Al | |||

| Aluminum Alloy | YH-331 | S331 | ER5183 | High strength, good corrosion resistance ability, and used for aluminum alloy TIG welding | |||||||||

| ≤0.10 | ≤0.40 | ≤0.40 | 0.50~1.00 | 4.3~5.2 | 0.05~0.25 | ≤0.25 | ≤0.15 | Rem | |||||

Links:https://www.globefindpro.com/products/101192.html

-

Anti-corrosive Aluminium Sheet

Anti-corrosive Aluminium Sheet

-

Radiator Aluminium Sheet

Radiator Aluminium Sheet

-

Standard Traffic Sign Aluminium Sheet

Standard Traffic Sign Aluminium Sheet

-

ER50-4, A18, ER70S-4, YGW12 Mild Steel Welding Wire

ER50-4, A18, ER70S-4, YGW12 Mild Steel Welding Wire

-

Square Aluminium Sheet

Square Aluminium Sheet

-

Traffic Sign Aluminium Disc

Traffic Sign Aluminium Disc

-

ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

ER310, H1Cr26Ni21, Y310 Stainless Steel Welding Wire

-

S331, ER5183 Aluminum Welding Wire

S331, ER5183 Aluminum Welding Wire

-

S311, ER4043 Aluminum Welding Wire

S311, ER4043 Aluminum Welding Wire

-

E551T1-B2, E81T1-B2 Flux Core Welding Wire

E551T1-B2, E81T1-B2 Flux Core Welding Wire

-

E500T-1, E70T-1 Flux Core Welding Wire

E500T-1, E70T-1 Flux Core Welding Wire

-

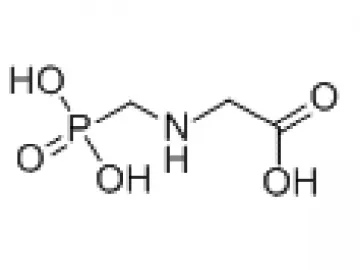

Glyphosate

Glyphosate