H08A, S1, EL12, S1 Submerged Arc Welding Wire

H08A, S1,EL12, S1 Submerged Arc Welding Wire

Description of H08A, S1, EL12, S1 Submerged Arc Welding Wire:

As a type of copper-coated carbon structural steel welding wire, YHM08A can work together with suitable weldingflux to realize submerged automatic arc welding, and the welding seam canachieve excellent mechanical properties.

Applicationof H08A, S1, EL12, S1 SubmergedArc Welding Wire:

By matching suitable welding flux, it is widely used for the submergedautomatic arc welding of carbon steel and mild alloy steel like 09Mn2, 16Mn,16MnCu, etc.

Standard-compliant:

| GB/T: H08A | BS: S1 |

| AWS: EL12 | DIN: S1 |

TechnicalParameters of H08A, S1,EL12, S1 Submerged Arc Welding Wire:

| Wire Type | Size | Inner Diameter | Outer Diameter | Net Weight | ||||

| Coil Packaging Wire | φ1.6~5.0(mm) | 300mm 620mm | 400mm 820mm | 25kg 250kg | ||||

| TIG Wire | Straight wire length: 1 meter | 5kg | ||||||

| Chemical Composition of Welding Wire (%) | C | Mn | Si | P | S | Cr | Ni | Cu |

| ≤0.10 | 0.30~0.55 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.20 | ≤0.30 | ≤0.20 | |

| Mechanical Properties or Deposited Metal | Yield strength σ0.2(Mpa) | Tensile Strength σb (Mpa) | Elongation δ5 (%) | AKV Impact (J) | ||||

| ≥320 | 410~550 | ≥22 | ≥34(-20) | |||||

| Common Wire Size (mm) | Welding Position | Electricity Polarity | ||||||

| φ2.0 | φ2.5 | φ3.0 | DC or AC | |||||

| φ3.2 | φ4.0 | φ5.0 | ||||||

Links:https://www.globefindpro.com/products/101234.html

-

ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

-

H08CrMoVA Submerged Arc Welding Wire

H08CrMoVA Submerged Arc Welding Wire

-

Felt Wheel

Felt Wheel

-

Felt Washer

Felt Washer

-

ER49-1, H08Mn2SiA Mild Steel Welding Wire

ER49-1, H08Mn2SiA Mild Steel Welding Wire

-

H13CrMoA, EB2 Submerged Arc Welding Wire

H13CrMoA, EB2 Submerged Arc Welding Wire

-

Fireproof felt (For Auto Use)

Fireproof felt (For Auto Use)

-

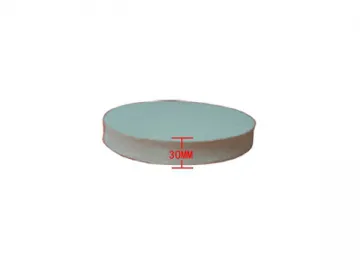

High-density Felt Wheel (For Polishing)

High-density Felt Wheel (For Polishing)

-

White Woolen Felt (For Exporting)

White Woolen Felt (For Exporting)

-

High-density Felt Wheel (For Polishing)

High-density Felt Wheel (For Polishing)

-

ER50-3, A15, ER70S-3, YGW16 Mild Steel Welding Wire

ER50-3, A15, ER70S-3, YGW16 Mild Steel Welding Wire

-

Ultrathin Felt

Ultrathin Felt