ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

Description ofER70S-G Mild Steel Welding Wire:

Except the normal elements of si, Mn, ER70S-G also contains Ti, which cangreatly help to produce more stable arc, less spatters and fumes, and also makethe welding seam has much higher tensile and yield strength.

Application of ER70S-G, ER50-G, YGW11 Mild SteelWelding Wire:

As a key type of welding supplies, it is suitable for butt welding, anglewelding and horizontal welding of the thick steel plate under high electricitycurrent in the fields of ship building, bridge, steel structure and engineeringmachinery.

Standard-compliant:

| GB/T: ER50-G | JIS: YGW11 |

| AWS:ER70S-G |

|

TechnicalParameters of ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire:

| Packaging | Wire Size | Spool Size | Net Weight | |||||

| φ0.8~1.6(mm) | D100mm D200mm D270mm D300mm K300mm | 1kg, 5kg, 15kg, 18kg, 20kg | ||||||

| Chemical Composition of Welding Wire (%) | C | Mn | Si | P | S | Cr | Ni | Cu |

| ≤0.15 | 1.40~1.90 | 0.55~1.10 | ≤0.030 | ≤0.030 | ≤0.10 | 0.12~0.20 | ≤0.50 | |

| Mechanical Properties or Deposited Metal | Yield Strength σ0.2(Mpa) | Tensile Strength σb(Mpa) | Elongtationδ5 (%) | AKV Impact (J) | ||||

| ≥420 | 500~600 | ≥22 | ≤0.50 | |||||

| Welding Wire Diameter (mm) | φ0.8 | φ0.9 | φ1.0 | φ1.2 | φ1.6 | Welding Position | ||

| Welding Current (AMP.) | 50~180 | 50~200 | 80~250 | 100~350 | 250~500 | |||

| Note | Welding wire should be stocked in dry environment. Open the packs just when welding, so as to avoid the wire rust. | |||||||

| Before welding, please clean out the oil, rust, water etc from the welding surface. | ||||||||

Links:https://www.globefindpro.com/products/101235.html

-

H08CrMoVA Submerged Arc Welding Wire

H08CrMoVA Submerged Arc Welding Wire

-

Felt Wheel

Felt Wheel

-

Felt Washer

Felt Washer

-

ER49-1, H08Mn2SiA Mild Steel Welding Wire

ER49-1, H08Mn2SiA Mild Steel Welding Wire

-

H13CrMoA, EB2 Submerged Arc Welding Wire

H13CrMoA, EB2 Submerged Arc Welding Wire

-

ER44-8 CO2 Gas Shielded Welding Wire

ER44-8 CO2 Gas Shielded Welding Wire

-

H08A, S1, EL12, S1 Submerged Arc Welding Wire

H08A, S1, EL12, S1 Submerged Arc Welding Wire

-

Fireproof felt (For Auto Use)

Fireproof felt (For Auto Use)

-

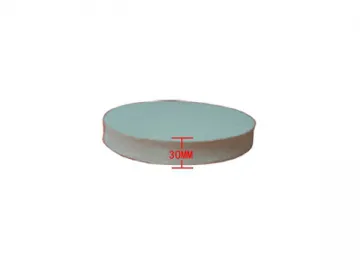

High-density Felt Wheel (For Polishing)

High-density Felt Wheel (For Polishing)

-

White Woolen Felt (For Exporting)

White Woolen Felt (For Exporting)

-

High-density Felt Wheel (For Polishing)

High-density Felt Wheel (For Polishing)

-

ER50-3, A15, ER70S-3, YGW16 Mild Steel Welding Wire

ER50-3, A15, ER70S-3, YGW16 Mild Steel Welding Wire