H08CrMoVA Submerged Arc Welding Wire

H08CrMoVA Submerged Arc Welding Wire

Description ofH08CrMoVA Submerged Arc Welding Wire:

Its weld metal is suitable for high-temperature environments, and the weldingseam is of higher strength in the medium and high temperature circumstances.

Applicationof H08CrMoVA Submerged Arc Welding Wire:

This key welding supplies is widely used in welding 12CrMoV, 15Cr1MoV,ZG20CrMoV and so on, and especially suitable for heat-resistant steel pressurevessels for pipeline welding, like reheat steam turbine for heat pipe segment,low-pass pipeline.

Standard-compliant:

GB/T:H08CrMoVA

TechnicalParameters of H08CrMoVA Submerged Arc Welding Wire:

| Wire Type | Size | Inner Diameter | Outer Diameter | Net Weight | |||||||

| Coil Packaging Wire | φ1.6~5.0(mm) | 300mm 620mm | 400mm 820mm | 25kg 250kg | |||||||

| TIG Wire | Straight wire length: 1 meter | 5kg | |||||||||

| Chemical Composition of Welding Wire (%) | C | Mn | Si | P | S | Cr | Ni | Mo | V | Cu | |

| ≤0.10 | 0.40~0.70 | 0.15~0.35 | ≤0.030 | ≤0.030 | 0.80~1.10 | ≤0.30 | 0.50~0.70 | 0.15~0.35 | ≤0.20 | ||

| Mechanical Properties or Deposited Metal | Yield strength σ0.2(Mpa) | Tensile Strength σb (Mpa) | Elongation δ5 (%) | AKV Impact (J) | |||||||

| ≥275 | 450~585 | ≥22 | - | ||||||||

| Wire diameter | φ2.0 | φ3.0 | φ4.0 | φ5.0 | |||||||

| Note | Welding Position | ||||||||||

| Welding wire should be stocked in dry environment. Open the packs just when welding to avoid the wire rust. |

| ||||||||||

| Before welding, please clean out the oil, rust, water etc from the welding surface. |

| ||||||||||

Links:https://www.globefindpro.com/products/101237.html

-

Felt Wheel

Felt Wheel

-

Felt Washer

Felt Washer

-

ER49-1, H08Mn2SiA Mild Steel Welding Wire

ER49-1, H08Mn2SiA Mild Steel Welding Wire

-

H13CrMoA, EB2 Submerged Arc Welding Wire

H13CrMoA, EB2 Submerged Arc Welding Wire

-

ER44-8 CO2 Gas Shielded Welding Wire

ER44-8 CO2 Gas Shielded Welding Wire

-

H10Mn2, S4, EH14, S501-H Submerged Arc Welding Wire

H10Mn2, S4, EH14, S501-H Submerged Arc Welding Wire

-

ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

-

H08A, S1, EL12, S1 Submerged Arc Welding Wire

H08A, S1, EL12, S1 Submerged Arc Welding Wire

-

Fireproof felt (For Auto Use)

Fireproof felt (For Auto Use)

-

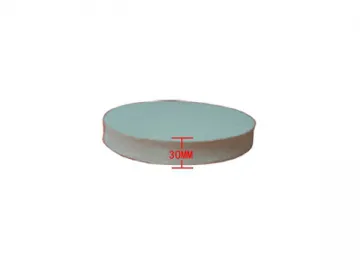

High-density Felt Wheel (For Polishing)

High-density Felt Wheel (For Polishing)

-

White Woolen Felt (For Exporting)

White Woolen Felt (For Exporting)

-

High-density Felt Wheel (For Polishing)

High-density Felt Wheel (For Polishing)