ER49-1, H08Mn2SiA Mild Steel Welding Wire

ER49-1, H08Mn2SiA Mild Steel Welding Wire

Description ofER49-1 Mild Steel Welding Wire:

Under the protection of the copper layer, this ER49-1Mild Steel Welding Wire iswith high anti-corrosion ability and excellent welding properties. Based on thecombined deoxidation of MnSi, the welding seams have excellent mechanicalproperties without weld porosity and slag appearance.

Applicationof ER49-1, H08Mn2SiA Mild Steel Welding Wire:

Being an important welding supplies for welding process, it is widely used forCO2 gas shielded semi-automatic and automatic welding to produce marineboilers, marine pipelines, marine cargo, deck and container, which are made ofship building steel (A32, E32, D32, A36, E36, D36) and plain low carbon steelwith strength at 490N/mm2 degree, as well as mild alloy steel 16Mn, 15Mn etc.

Standard-compliant:

GB/T: ER49-1 H08Mn2SiA

TechnicalParameters of ER49-1, H08Mn2SiA Mild Steel Welding Wire:

| Packaging | Wire Size | Spool Size | Net Weight | |||||

| φ0.8~1.6(mm) | D100mm D200mm D270mm D300mm K300mm | 1kg , 5kg, 15kg, 18kg, 20kg | ||||||

| Chemical Composition of Welding Wire (%) | C | Mn | Si | P | S | Cr | Ni | Cu |

| ≤0.11 | 1.80~2.10 | 0.65~0.95 | ≤0.030 | ≤0.030 | ≤0.20 | ≤0.30 | ≤0.50 | |

| Mechanical Properties or Deposited Metal | Yield Strength σ0.2(Mpa) | Tensile Strength σb(Mpa) | Elongtationδ5 (%) | AKV Impact (J) | ||||

| ≥372 | ≥490 | ≥20 | ≥47(Room temperature) | |||||

| Welding Wire Diameter (mm) | φ0.8 | φ1.0 | φ1.2 | φ1.6 | Welding Position | |||

| Welding Current (AMP.) | 40~140 | 50~220 | 80~350 | 120~450 | ||||

| Note | Welding wire should be stocked in dry environment. Open the packs just when welding, so as to avoid the wire rust. | |||||||

| Before welding, please clean out the oil, rust, water etc from the welding surface. | ||||||||

Links:https://www.globefindpro.com/products/101242.html

-

H13CrMoA, EB2 Submerged Arc Welding Wire

H13CrMoA, EB2 Submerged Arc Welding Wire

-

ER44-8 CO2 Gas Shielded Welding Wire

ER44-8 CO2 Gas Shielded Welding Wire

-

H10Mn2, S4, EH14, S501-H Submerged Arc Welding Wire

H10Mn2, S4, EH14, S501-H Submerged Arc Welding Wire

-

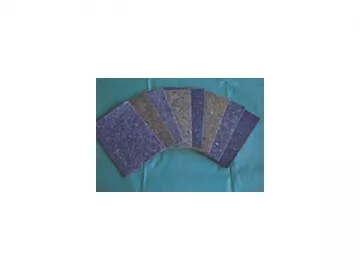

Color Woolen Felt

Color Woolen Felt

-

Felt Disc (For Polishing)

Felt Disc (For Polishing)

-

ER304, H0Cr18Ni9 Stainless Steel Welding Wire

ER304, H0Cr18Ni9 Stainless Steel Welding Wire

-

Felt Washer

Felt Washer

-

Felt Wheel

Felt Wheel

-

H08CrMoVA Submerged Arc Welding Wire

H08CrMoVA Submerged Arc Welding Wire

-

ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

ER70S-G, ER50-G, YGW11 Mild Steel Welding Wire

-

H08A, S1, EL12, S1 Submerged Arc Welding Wire

H08A, S1, EL12, S1 Submerged Arc Welding Wire

-

Fireproof felt (For Auto Use)

Fireproof felt (For Auto Use)