Vapor Recovery Equipment

Vapor Recovery Equipment

Vapor Recovery Equipment

Oil Recovery Equipment

The filling station oil recovery system consists of an oil recoveryautomatic nozzle, vacuum pump, pipe, breakaway value and gas and oil separatorvalve, etc.

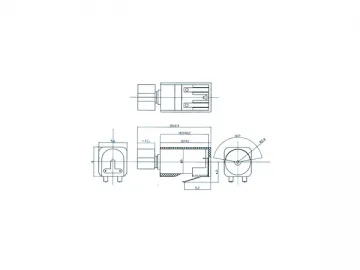

Oil Recovery Nozzle

Description

1.The oil recovery nozzle offers easy operation and a safe and stableperformance.

2. It offers a builtin A&L control valve.

3. It works under a certain pressure,thus avoid fuel injection.

4. The oil recoverynozzle is used in all kinds of fuel dispensers.

Performance Parameters

Flow rate: 45 L/Min

Working Pressure: 0.5~3.5Bar

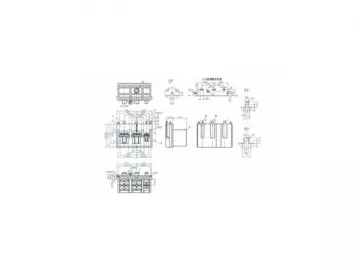

Vacuum Pump

Description

1. It is a rotary vane vacuum pump.

2. The pump with motor does not affect the fuel dispenser duringnormal operation,

3. The vacuum pump is compact in size and self-lubricating.

5. It offers one head and two heads to equip one nozzle and two nozzles.

Performance Parameters

| Model | VRP-1 | VRP-2 |

| Max. Flow Rate | 65 L /Min | 120 L /Min |

| Working Temperature | -25~ 50 ℃ | -25~ 50 ℃ |

| Max.Vacuum | 0.07MPa | 0.07MPa |

| Motor Speed | 2800RPM | 2800RPM |

| Motor Power | 370W | 370W |

| Power Supply | 380V/50Hz or 220V/50Hz | 380V/50Hz or 220V/50Hz |

| Noise | ≤70dB | ≤70dB |

| Connection | G1/4” | G3/8” |

Pipe

Description

Each pipe is equipped with an oil and gas separator valve and a breakaway valve. The pipe fits for the oil recovery system.

Oil & Gas Separator Valve

Description

The oil and gas separator valve divides the coaxial tube into oilroute and gas route. There is no need for maintenance or repair work.

Breakaway Valve

Description

The breakaway valve features a double valves structure,while separated, cutting off oil and gas without leaking. Itoffers accidental pulling off and only needs a special screw to resume thework. The axial pulling off force isabout 125Kgs.

Cowell is aprofessional vapor recovery equipment manufacturer based in China. We offer various types ofproducts such as LPG sliding-vane pump, manual nozzle, positive displacementflow meter, demountable sample taker, and electric transfer pump unit.

Links:https://www.globefindpro.com/products/102088.html

-

Mechanical Control System, Pneumatic Control System

Mechanical Control System, Pneumatic Control System

-

Φ4 Spring Reed Micro Vibrating Motor A2

Φ4 Spring Reed Micro Vibrating Motor A2

-

Standard Metal Prover

Standard Metal Prover

-

Stand Hair Dryer

Stand Hair Dryer

-

Other Tank Truck Parts

Other Tank Truck Parts

-

Nose Trimmer

Nose Trimmer

-

Φ4 Spring Reed Micro Vibrating Motor A1

Φ4 Spring Reed Micro Vibrating Motor A1

-

Demountable Sample Taker

Demountable Sample Taker

-

Quick Couplers

Quick Couplers

-

Vapor Recovery Adaptor, Valve

Vapor Recovery Adaptor, Valve

-

Binding Post

Binding Post

-

Φ5 Spring Reed Micro Vibrating Motor B1

Φ5 Spring Reed Micro Vibrating Motor B1