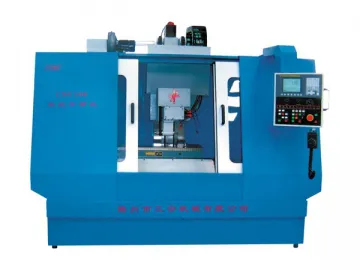

Vertical Machine Center VMC10562/VMC8046

Vertical Machine Center VMC10562/VMC8046

1. Vertical Machine Center VMC10562

Features and Advantages

1. Ourvertical machine center VMC10562 features a huge base andhigh-strength column for ensuring the machine tools' rigidity and stability.

2. The X/Y/Z axes use aroll-on linear guide way to improve their weight taking, structural rigidityand damping capacity. This alsoguarantees its transmission accuracy and stability.

3. Our vertical machinecenter has the advantage of float-typebuffering tools structure. As a result,the damage of spindle bearing upon tool changing can be avoidedand its service life is improved.

4. The oil-waterseparation structure can avoid the decomposition of coolant, improve itsservice life and save on cost.

5. Our vertical machinecenter hasa 24 sets tool magazine, which can effectively shorten the toolchanging time.

6. The lead screw guide way uses soundand automatic clearance lubrication to ensure the motion accuracy of functionalparts and extends the service life.

7. The enclosed electriccabinet aided with air circulation design has the advantages of dustprevention, ventilation and sound cooling effect.

Technical Specifications

| Item No. | 383115 |

| Моdel | VMC10562 |

| Table size (L х W) | 1000 х 550mm |

| Max. table load | 800 kg |

| Spindle taper | ISO BT40 |

| Spindle speed | 500-8000 rpm |

| Spindle motor power | 11kW (15 HP) |

| X axis travel | 1050 mm |

| Y axis travel | 620 mm |

| Z axis travel | 610 mm |

| X/Y/Z axis rapid feed speed | 24000mm/min |

| X/Y axis feed speed | 6-3200 mm/min |

| Z axis feed speed | 1-8000 mm/min |

| Positioning accuracy | ±0,015/300 mm |

| Repositioning accuracy | ±0,003 mm |

| CNC system | Mitsubishi, Fanuc, Siemen etc. (Optional) |

| Tools No. | 24 |

| Overall dimensions | 2800х2800х2850 mm |

| N.W/G.W | 8000/8400 kg |

2. Vertical Machine Center VMC8046

Advantages

1. Our vertical machine center VMC8046 features high-speed and a precise spindle unit. It ensures high precision, high efficiencyand long service life.

2. Direct connection ofthree servo motors and ball screw by coupler has the advantages of minimumtransmission error, nonexistence of rotation difference, and sound dynamicproperty.

3. The prestretching of the screw can improve the rigidity ofpower transmission system.

4. Our vertical machinecenter VMC8046 uses a rolling guide at X and Y directions to speed up the movementand make a rapid response. It uses abroadly rectangular rolling guide at Z direction with the surface hardened andplastic-coated for bearing a large cutting area.

5. The bamboo-hat type magazine tool can realize automatic toolchanging. Multi processing featured witha high degree of automation can be achieved after clamping the workpiece.

6. The screw guide wayuses sound and automatic clearance lubrication to ensure the motion accuracy ofthe functional parts and extends the service life.

7. Our vertical machine center VMC8046 uses a cost-effective CNC system featured with online functions to realizeman-machine interaction and get high intelligentization.

Technical Specifications

| Item No. | 383111 |

| Моdel | VMC8046 |

| Table size (L х W) | 1000 х 550 mm |

| Max. table load | 800 кg |

| Spindle taper | ISO BT40 |

| Spindle speed | 200-8000rpm |

| Spindle motor power | 5.5/7.5 кW |

| X axis travel | 800 mm, 1050 mm (Optional) |

| Y axis travel | 440 mm |

| Z axis travel | 500 mm |

| X/Y/Z axis rapid feed speed | 12000 mm/min |

| X/Y axis feed speed | 1-3200 mm/min |

| Z axis feed speed | 1-2000 mm/min |

| Positioning accuracy | ±0,015 mm |

| Repositioning accuracy | ±0,005 mm |

| CNC system | Mitsubishi, Fanuc, Siemens etc. (Optional) |

| Tools No. | 16 |

| Overall dimensions | 2500х2300х2700 mm |

| N.W/G.W | 4500/4800kg |

TRI-UNION is a China-based vertical machine centermanufacturer and supplier. We offervertical machine centers, portable belt sanders, hand shears, etc. Our high quality products are offered atcompetitive prices. We can supply thefull chain of manufacturing arbor presses, rotary machines, etc. right here in China. Our lower manufacturing cost saves yourpurchasing cost. More details on each ofour products are shown on the description page.

Links:https://www.globefindpro.com/products/103257.html

-

CNC Slot Machine Center CNC80/100/120

CNC Slot Machine Center CNC80/100/120

-

CNC Boring and Milling Machine TXK68

CNC Boring and Milling Machine TXK68

-

CNC Lathe CTK6416

CNC Lathe CTK6416

-

CNC Boring and Milling Machine TH800

CNC Boring and Milling Machine TH800

-

Slip Roll Machine European Design W01-2x1000

Slip Roll Machine European Design W01-2x1000

-

Magnetic Bending Machine

Magnetic Bending Machine

-

Pan and Box Brake W Serials

Pan and Box Brake W Serials

-

Bender/Brake

Bender/Brake

-

Precision Folding Machine MFS2020, MF3020

Precision Folding Machine MFS2020, MF3020

-

Slip Roll Machine

Slip Roll Machine

-

Hand Brake W Serials

Hand Brake W Serials

-

Electric Rolling Machine

Electric Rolling Machine