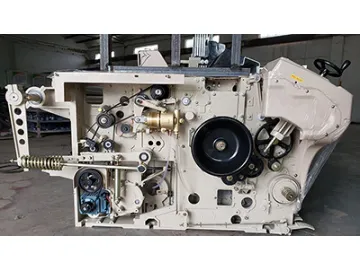

JW8200 Water jet loom

The JW8200 high-speed water jet loom features a higher production efficiency than the JW400 and JW822 water jet looms, with a shift weft density and weaving speed.

The water jet loom features an integrated machine rack, high machine rigidity, advanced electronic control system, stable weft insertion and a beating up mechanism. Four- or six-link crank beating is available. The water consumption of the JW8200 water jet loom is 30% lower than other looms. This water jet weaving machine is suitable for weaving hydrophobic fabrics, medium-weight and heavy fabrics and industrial textiles with plain, twill, satin or jacquard weaves. Spark’s state-of-the-art water jet loom is also able to weave heavy fabrics up to 600g/m2.

| Application | Denier water resistant chemical fabric,fabric up to 600g/m2 |

| Breadth(cm) | 190, 210, 230, 280, 340, 360, 380 |

| Designed speed | 600~1300RPM |

| Weaving Range | Filament: 20 D- 1350 D |

| Weft selection | 1 color, 2 colors, 3 colors or 4 colors |

| Loom beam disc diameter (mm) | 800 |

| Roller Diameter (mm) | 550 |

| Shedding | Plain shedding , Positive cam shedding, Dobby shedding |

| Beating up | Double connection rod assembly four-bar beating-up |

| Selvedge | Raw edge, mechanical tuck-in selvedge |

| Let-off device | Electronic let-off |

| Take-up | Electronic take-up |

Scan QR to Read

Links:https://www.globefindpro.com/products/10342.html

Links:https://www.globefindpro.com/products/10342.html

Recommended Products

-

JW408 Water jet loom

JW408 Water jet loom

-

LED Transformers--Use Indoor or Outdoor

LED Transformers--Use Indoor or Outdoor

-

Air Compressor Parts and Accessories

Air Compressor Parts and Accessories

-

LED Transformers --IP67/LED power supplies / LED Drivers

LED Transformers --IP67/LED power supplies / LED Drivers

-

SMD3528 LED Strip Lights (9.6W)

SMD3528 LED Strip Lights (9.6W)

-

YC920 Air jet loom

YC920 Air jet loom

-

MJX262D(1.5W)

MJX262D(1.5W)

-

YC9000 Air jet loom

YC9000 Air jet loom

-

LED Transformers --Economic Type

LED Transformers --Economic Type

-

SMD2835 LED Strip Lights (7.2W)

SMD2835 LED Strip Lights (7.2W)

-

MJX266E(1.2W)

MJX266E(1.2W)

-

LED Neon Flex (Extrusions)

LED Neon Flex (Extrusions)

Hot Products