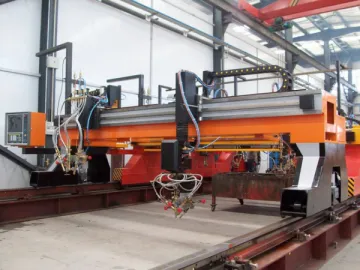

Heavy Duty Oxy-Fuel Cutting Machine

HeavyDuty Oxy-Fuel Cutting Machine

The CNCDHG heavy duty oxy-fuel cutting machine is a key part of the continuouscasting line for cutting thick plate. Itis used for thermal cutting the billet steel in high temperature.

Main Configurations

Cutter, regulator, torch, lifter, track bracket, energy transmission lines,towline, cooling system and electric apparatus control device.

Features

1. By using gantry trackstructure, the heavy duty oxy-fuel cutting machine can easily regulate the positionof the torches for the cut of billet steel.

2. The water cycle for coolingthe plates can guarantee the normal operation of the cutting machine even whenthe ambient temperature is high.

3. The cutting speed of the heavy duty oxy-fuel cutting machine is regulated bythe imported servo motor, ensuring convenient operation.

4. The torch uses advancedcomposite structure and perfect cooling system.

5. The flame can be focused whencutting the round pieces. Flux can beadded to cut the stainless steel.

6. The heavy duty oxy-fuel cutting machine is equipped with a voltagestabilizer and remote dropping system to ensure the stable gas supply andremote control.

7. It features high reliability, high precision, high efficiency, low gasconsumption, etc.

8. Max cutting thickness: 2m. The cutting machine can cut out complexgeometrical figures from the forge pieces.

Technical Specifications

| Model | Parameters |

| Rail Span | ≥3-4m |

| Driving Mode | Single-side |

| Rail Length | ≥4m (can be customized) |

| Effective Cutting Width | 0.8m less than rail length |

| Effective Cutting Length | 2m less than vertical rail length |

| Max Cutting Thickness | 1000mm-2000mm |

| Max Freewheeling Speed | 6000mm/min |

| Torch Numbers | One CNC auto ignition |

| Cutting Mode | Flame (oxy-fuel) |

| Driving Motor | Panasonic, Mitsubishi, Yaskawa |

| Gear Box | Imported from Germany |

| Numerical Control System | American START |

| Water Cycle for Cooling Plates | Standard fitting |

| Base for Installing Guide Rail (bearing beam, cement concrete) | Made by users based on the drawing offered by manufacturer |

| Vertical Pipeline Towline Bracket | Made by users based on the drawing offered by manufacturer |

| Primary Power Supply Wires and Edge Connection | Made by users based on the drawing offered by manufacturer |

| Primary Air Supply Device | Made by users based on the drawing offered by manufacturer |

| Execute Standard | International standard: ISO9013-2002 and ISO8206-1991 |

TAYOR is a professional heavyduty oxy-fuel cutting machine manufacturer, based in China. Our main products are welding machine,automatic welding machine, CNC steel plate cutting machine and steel platecutting machine. Located in Shanghai, we can provideconvenient sea transportation and plentiful labor, enabling us to provide ourhigh quality products at low prices. For more information, please feel free to contactus via email or at the contact addresses available on this website.

Links:https://www.globefindpro.com/products/104164.html

-

2D Laser Engraver Super Jet

2D Laser Engraver Super Jet

-

Strip Oxy-Fuel Cutting Machine

Strip Oxy-Fuel Cutting Machine

-

CNC Oxy-Fuel and Plasma Cutting Machine

CNC Oxy-Fuel and Plasma Cutting Machine

-

CNC Oxy-Fuel Pipe Cutting Machine

CNC Oxy-Fuel Pipe Cutting Machine

-

Curve Bevel CNC Oxy-Fuel Cutting Machine

Curve Bevel CNC Oxy-Fuel Cutting Machine

-

INOVA 3D Camera

INOVA 3D Camera

-

CNC Steel Plate Cutting Machine (Gantry Type)

CNC Steel Plate Cutting Machine (Gantry Type)

-

Lamp-Pump YAG Laser Marker YAG-M50

Lamp-Pump YAG Laser Marker YAG-M50

-

Laser Welder

Laser Welder

-

Stainless Steel Relief Decor

Stainless Steel Relief Decor

-

Portrait Stone Sculpture

Portrait Stone Sculpture

-

Fiber Laser Marker YLP-F10/ F20

Fiber Laser Marker YLP-F10/ F20