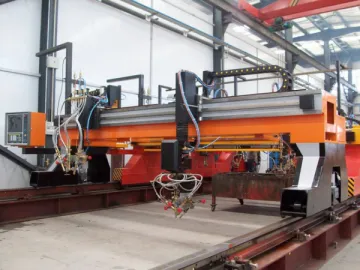

CNC Oxy-Fuel and Plasma Cutting Machine

CNC Oxy-Fuel and Plasma Cutting Machine

Features

1. It uses a gantry or box type welded structure and has been annealed.

2. The CNC oxy-fuel and plasma cutting machine features long service life, steady operation, durability and high duty cycle.

3. It has gapless gearingtransmit, stable and smooth running in high speed, high qualitycut surface.

4. The integrated auto ignition with automatic height controller, regulates the height between the cutting torch andwork piece, realizing the best cutting quality.

5. The CNC oxy-fuel and plasma cutting machine can realize multi-torch mirrorimage cutting or synchronism cutting, improving cutting efficiency.

6. It features low operation and maintenance cost, dispenses withspecial maintenance, friendly operation interface, and is easy to learn how to operate

7. It has a utility CNC system and is reliable and safe. It has automatic programming, optimizationnesting and piercing path, and it effectively saves steel.

Application

The CNC oxy-fuel andplasma cutting machine is used in shipbuilding, H beam building, constructionmachinery building, the steel industry, etc.

Optional

Powder marking device

Stripe cutting torch

Straight line triple beveling torch

Rotary triple flame curve beveling torch

Rotary plasma curve beveling torch

Push-pull type working table and dust extraction

Water surface and underwater plasma working table

Above machines can becustomized.

Accurate reference standard: JB/T10045.3-1999 and DIN2310

Technical Specifications

| Technical Specification | ||||||

| Cutting Width (mm) | 2200 | 2700 | 3200 | 4200 | 5200 | Can be customized |

| Track Width (mm) | 3000 | 3500 | 4000 | 5000 | 6000 | 800mmless than width |

| Cutting Length (m) | 2m less than track length | |||||

| Suggested Cutting Thickness (mm) | Oxy-fuel:6-120(Max 300mm)/Plasma:1-80 | |||||

| Basic Components | ||||||

| Cutting Mode | Plasma/Oxy-fuel | |||||

| Drive Motor Number | Dual-side | |||||

| Cutting Torch Number | Customization | |||||

| Height Controller | Automatic height controller | |||||

| Driving Motor | Servo motor | |||||

| CNC Controller | SJTU-SK/Micro EDGE/EDGE pro/KP | |||||

| Available Plasma Power | Hypertherm/Thermadyne/Kjellberg/TAYOR LGK | |||||

| Nesting Software | FASTCAM | |||||

| Power Voltage | 3×380V±10% 50Hz or according to user’s local condition | |||||

| Operation Language | Multilanguage | |||||

TAYOR is a CNC oxy-fuel andplasma cutting machine manufacturer, based in China. We offer different steel plate cuttingmachines for different applications. Withhigh quality and stable performance, our CNC steel plate cutting machine,welding machine and automatic welding machine are well received by customers inRussia, Ukraine, Poland, Kazakhstan, Saudi Arabia, Iran, and more. We encourage you to browse through our siteand read our articles to learn more about our CNC steel plate cutting machines. Please feel free to contact us at any time.

Links:https://www.globefindpro.com/products/104167.html

-

CNC Oxy-Fuel Pipe Cutting Machine

CNC Oxy-Fuel Pipe Cutting Machine

-

Curve Bevel CNC Oxy-Fuel Cutting Machine

Curve Bevel CNC Oxy-Fuel Cutting Machine

-

INOVA 3D Camera

INOVA 3D Camera

-

Bevel CNC Plasma Cutting Machine

Bevel CNC Plasma Cutting Machine

-

Laser Cutter

Laser Cutter

-

High Definition CNC Plasma Cutting Machine

High Definition CNC Plasma Cutting Machine

-

Strip Oxy-Fuel Cutting Machine

Strip Oxy-Fuel Cutting Machine

-

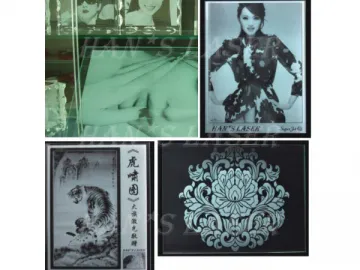

2D Laser Engraver Super Jet

2D Laser Engraver Super Jet

-

Heavy Duty Oxy-Fuel Cutting Machine

Heavy Duty Oxy-Fuel Cutting Machine

-

CNC Steel Plate Cutting Machine (Gantry Type)

CNC Steel Plate Cutting Machine (Gantry Type)

-

Lamp-Pump YAG Laser Marker YAG-M50

Lamp-Pump YAG Laser Marker YAG-M50

-

Laser Welder

Laser Welder