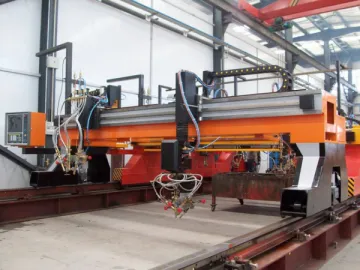

Bevel CNC Plasma Cutting Machine

BevelCNC Plasma Cutting Machine

Working Theory

Based on the existing CNCcutting technology, the bevel CNC plasma cutting machine is added with two moving controlshafts to separately control the electric rotating machine and bevel deflectionelectric machine. While simultaneouslymonitoring the change of bevel angle and rotating angle during cutting process,it can precisely cut out the shape and bevel for the plate.

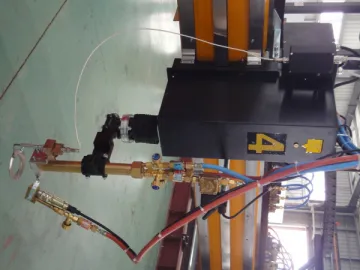

Configurations of Rotary Torches’Control System

Rotary control, bevel angle control, torch lifting control, torch auto heightcontrol system

Rotary Control System

By controlling the AC servo motor, the fifth shaft of the CNC card can controlthe rotation. Once users know the servoparameter, gear box parameter, and output gear parameter, they can get theimpulse of the rotator. When cutting outa bevel for a component, the bevelCNC plasma cutting machine can control the rotationof the rotator by “G” code file.

Bevel Angle Control System

By controlling the AC servo motor, the sixth shaft of the CNC card can monitorthe cutting of the bevel angle. The manualsetting or G code automatic setting of the bevel angle is available accordingto the needs.

The basic theory for the numerical control software is interpolation theory. When added with two control shafts to therotary torch, the bevel CNC plasma cutting machine can cut the plate by usingthe “G” code file.

Application

Using plasma cutting mode, the bevelCNC plasma cutting machine is used for preciselycutting stainless steel with the thickness of 0.5-160mm, carbon steel, nonferrousmetal, etc. It can also cut out thebevel with the thickness of 8-40mm.

Technical Specifications

| Model | Parameters | |

| Rail Span | 3-10m | |

| Driving Mode | Dual-side | |

| Rail Length | 12-50m or can be customized | |

| Effective Cutting Width | 0.8m less than rail span | |

| Effective Cutting Length | 2m less than vertical rail length | |

| Cutting Thickness | 8-40mm | |

| Bevel Angle | ±45° | |

| Max Freewheeling Speed | 9000mm/min (adjustable, max speed can reach 25mm/min) | |

| Torch Number | One group of plasma | |

| Cutting Mode | Plasma cutting (oxygen, nitrogen, H2, H35, F5, H20, etc.) | |

| Driving Motor | Japanese Panasonic, Mitsubishi, Yaskawa | |

| Gear Box | Import from Germany | |

| Numerical Control System | American Hypertherm, KP, etc. | |

| Plasma Power | American Hypertherm, Thermadyne and Germany Kjellberg | |

| Nesting Software | FASTCAM, TOL, APNS2000 | |

| Optional | Marking device, inking device, perforating device, air conditioner, laser scriber, dust extraction, etc. | |

| Base for Installing Guide Rail (bearing beam, cement concrete) | Made by users based on the drawing offered by manufacturer | |

| Work Table | Made by users based on the drawing offered by manufacturer | |

| Vertical Pipeline Towline Bracket | Made by users based on the drawing offered by manufacturer | |

| Primary Power Supply Wires and Edge Connection | Made by users based on the drawing offered by manufacturer | |

| Primary Air Supply Device | Made by users based on the drawing offered by manufacturer | |

| Exhaust Equipment and Dust Removing Device | Bought by users | |

| Execute Standard | International standard: ISO9013-2002 and ISO8206-1991 |

If you are looking for a bevelCNC plasma cutting machine, we at TAYOR can help you with your needs. As a China-based steel plate cutting machine manufacturerand supplier, we enjoy low land, material, and labor costs. We can produce high quality CNC pipe cuttingmachine, welding machine and CNC steel plate cutting machine at reduced costs. For more detailed information about any of ourproducts, please feel free to contact us via any contact method listed on thewebsite.

Links:https://www.globefindpro.com/products/104171.html

-

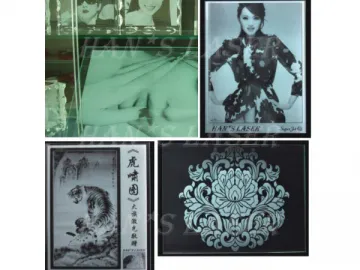

Laser Cutter

Laser Cutter

-

High Definition CNC Plasma Cutting Machine

High Definition CNC Plasma Cutting Machine

-

Thin Metal Sheet Laser Cutter CS035F-50X 200X

Thin Metal Sheet Laser Cutter CS035F-50X 200X

-

CNC Plasma Pipe Cutting Machine

CNC Plasma Pipe Cutting Machine

-

Laser Welder MOLD 301

Laser Welder MOLD 301

-

CNC Oxy-Fuel Cutting Machine

CNC Oxy-Fuel Cutting Machine

-

INOVA 3D Camera

INOVA 3D Camera

-

Curve Bevel CNC Oxy-Fuel Cutting Machine

Curve Bevel CNC Oxy-Fuel Cutting Machine

-

CNC Oxy-Fuel Pipe Cutting Machine

CNC Oxy-Fuel Pipe Cutting Machine

-

CNC Oxy-Fuel and Plasma Cutting Machine

CNC Oxy-Fuel and Plasma Cutting Machine

-

Strip Oxy-Fuel Cutting Machine

Strip Oxy-Fuel Cutting Machine

-

2D Laser Engraver Super Jet

2D Laser Engraver Super Jet