High Definition CNC Plasma Cutting Machine

High Definition CNC Plasma Cutting Machine

Product Description

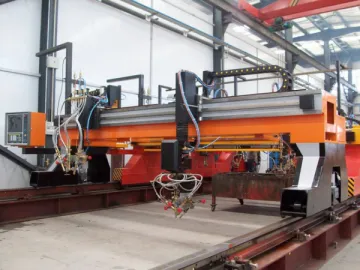

This cutting machine is a high definition CNC plasma cutting machine. It is a type of thermal cutting automatedequipment featuring multi-function, high efficiency and high reliability.

Configurations

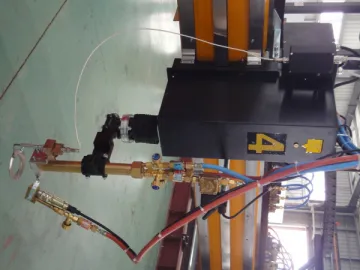

1. The high definition CNCplasma cutting machine uses gantry structure. The beam has been annealed to relieve thestress, so it features excellent rigidity and non-deformation.

2. Thevertical guide rail uses railway track materials. It features high precision and durabilityafter grinding of the surface. Thelength of the guide rail is 2m and can be customized.

3. The cross guide rail of the high definitionCNC plasma cutting machine features high precision and steady operation.

4. The cutting machine is equipped with an imported precision gear speedreducer.

5. The lifter of the high definition CNC plasma cutting machine is driven bythe servo motor or DC motor, shafted by the lead screw and guided by beelinebearing, ensuring the precise cutting.

6. The torch uses a 360°anti-collisiondesign, protecting the torch from damage caused by collision.

Functions

The high definition CNC plasma cutting machine has auto-positioning,auto-punch, auto-ignition and auto-height control functions.

Technical Specifications

| Model | Parameters | |

| CNCG small and medium span high definition CNC plasma cutting machine | CNCSG long span high definition CNC plasma cutting machine | |

| Rail Span | <4m | ≥6-10m |

| Driving Mode | Single-side | Dual-side |

| Rail Length | Can be customized | |

| Effective Cutting Width | 0.8m less than rail span | |

| Effective Cutting Length | 2m less than vertical rail length | |

| Cutting Thickness | Flame 5-150mm (special type: 300), plasma 5-150mm (or thicker) | |

| Max Freewheeling Speed | ≥9000mm | |

| Torch Number | Standard configuration: one group of CNC flame torch, auto ignition, capacitance height control | |

| Torch Number | Standard configuration: one group of CNC plasma cutting, arc voltage adjusting controller | |

| Cutting Mode | Flame (oxy-fuel) Plasma (air, oxygen, nitrogen, H2, H35, F5, H20, etc.) | |

| Driving Motor | Panasonic, Mitsubishi, Yaskawa | |

| Gear Box | Imported from Germany | |

| Numerical Control System | American Hypertherm, TAYOR-CNCⅡ, KP, FAST, etc | |

| Plasma Power | American Hypertherm, Thermadyne and Germany Kjellberg | |

| Nesting Software | FASTCAM, TOL, APNS2000 | |

| Optional | Bevel cutting torch, marking device, triple piercing device, high-low preheater, inking device, perforating device, manual torch device, air conditioner, laser scriber, dust extraction, etc. | |

| Base for Installing Guide Rail (bearing beam, cement concrete) | Made by users based on the drawing offered by manufacturer | |

| Work Table | Made by users based on the drawing offered by manufacturer | |

| Vertical Pipeline Towline Bracket | Made by users based on the drawing offered by manufacturer | |

| Primary Power Supply Wires and Edge Connection | Made by users based on the drawing offered by manufacturer | |

| Primary Air Supply Device | Made by users based on the drawing offered by manufacturer | |

| Exhaust Equipment and Dust Removing Device | Bought by users | |

| Execute Standard | International standard: ISO9013-2002 and ISO8206-1991 | |

TAYOR, a professional steelplate cutting machine manufacturer and supplier based in China, can provide high definitionCNC plasma cutting machine, bevel CNC plasma cutting machine and strip oxy-fuelcutting machine. We welcome you tochoose. If you are interested in our steel platecutting machines, please feel free to contact us.

Links:https://www.globefindpro.com/products/104173.html

-

Thin Metal Sheet Laser Cutter CS035F-50X 200X

Thin Metal Sheet Laser Cutter CS035F-50X 200X

-

CNC Plasma Pipe Cutting Machine

CNC Plasma Pipe Cutting Machine

-

Laser Welder MOLD 301

Laser Welder MOLD 301

-

CNC Oxy-Fuel Cutting Machine

CNC Oxy-Fuel Cutting Machine

-

Economic CNC Plasma Cutting Machine (Tabletop Split Type)

Economic CNC Plasma Cutting Machine (Tabletop Split Type)

-

Lamp-Pump YAG Laser Marker YAG-T80C

Lamp-Pump YAG Laser Marker YAG-T80C

-

Laser Cutter

Laser Cutter

-

Bevel CNC Plasma Cutting Machine

Bevel CNC Plasma Cutting Machine

-

INOVA 3D Camera

INOVA 3D Camera

-

Curve Bevel CNC Oxy-Fuel Cutting Machine

Curve Bevel CNC Oxy-Fuel Cutting Machine

-

CNC Oxy-Fuel Pipe Cutting Machine

CNC Oxy-Fuel Pipe Cutting Machine

-

CNC Oxy-Fuel and Plasma Cutting Machine

CNC Oxy-Fuel and Plasma Cutting Machine