Precision CNC Plasma Cutting Machine (Tabletop Integral Type)

Precision CNC PlasmaCutting Machine (Tabletop Integral Type)

Product Description

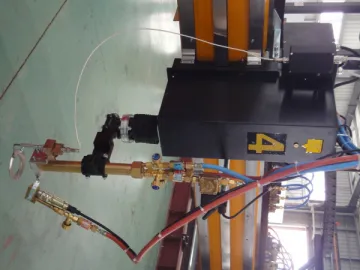

The CNCTMG precisionCNC plasmacuttingmachine(tabletopintegraltype) is a newly developed cutting machine withhigh speed and precision based on the development of the CNCTG table type cutting machine. High precision plasma and laser-like plasmacutting modes are available.

Configurations

The precision CNC plasma cutting machine consists of a control system, torches,machine body, two end brackets and beam. Both vertical and cross guide rail use highprecision ball linear guide rail. Thecutting machine uses integral type structure and beam uses welded boxstructure. A cross driving device andcross ball linear guide are installed for the beam.

Features

1. Precision CNC plasmacutting machine uses a dual-side driving mode, featuring a pair of uniformvertical driving devices. The precisionrack can drive the precision output gear by the servo motor on the end bracket,making the end bracket moving vertically. The cutting machine operates steadily and hashigh precision.

2. During the cross moving of the primary cutting torch, the torch can cutlinearly by precision gear rack of driving mode. The cutting shape can be customized by usingthe CNC system.

3. Cylinder exhaust equipment, draft fan and dust collector manufactured by ourcompany are optional. Combined with thecutting table and slag storage device, the uniquely designed draft fan canlargely reduce the dust, arc light, harmful gas, noise, etc., making themachine environmentally friendly.

4. The vertical pipeline towline bracket is contained, saving money forcustomers. The precision CNC plasmacutting machine is easy to install which reduces the installation and debuggingtime.

Applications

The precision CNC plasma cutting machine is especially used for fast cutting ofthin or medium-thin non-ferrous plates, stainless steel, aluminum plates and carbon-steelplates. It is used in industries likemachine manufacturing, metal working, etc.

Technical Specifications

| Model | Parameters |

| Rail Span | 1.5-3m |

| Driving Mode | Dual-side |

| Track Length | 4-12m or can be customized |

| Effective Cutting Width | 0.5m less than rail span |

| Effective Cutting Length | 1m less than vertical rail length |

| Cutting Thickness | 1-16mm |

| Max Freewheeling Speed | 9000mm/min (adjustable, can reach 25mm/min) |

| Torch Number | One CNC laser-like plasma |

| Cutting Mode | Plasma cutting (oxygen, nitrogen, H2, H35, F5, H20, etc.) |

| Driving Motor | Panasonic, Mitsubishi, Yaskawa, etc. |

| Gear Box | Imported from Germany |

| Rail | Imported beeline guide rail |

| Numerical Control System | American Hypertherm, TAYOR-CNCⅡ,KP, FAST, etc. |

| Plasma Power | American Hypertherm HPR series, Thermadyne UC series, Germany Kjellberg HF, FF series |

| Nesting Software | FASTCAM, TOL, APNS2000 |

| Optional | Slewing bevel cutting torch, marking device, inking device, perforating device, air conditioner, laser scriber, dust extraction, etc. |

| Work Table | Contained |

| Primary Power Supply Wires and Edge Connection | Made by users based on the drawing offered by manufacturer |

| Primary Air Supply Device | Made by users based on the drawing offered by manufacturer |

| Exhaust Equipment and Dust Removing Device | Optional |

| Executive Standard | International standard: ISO9013-2002and ISO8206-1991 |

If you are looking for a precisionCNC plasma cutting machine, we at TAYOR can help you with your needs. As a China-based CNC steel plate cuttingmachine manufacturer and supplier, we enjoy low land, material, and laborcosts. We can produce high quality CNCpipe cutting machine, welding machine and steel plate cutting machine atreduced costs. For more detailedinformation about any of our products, please feel free to contact us via anycontact method listed on the website.

Links:https://www.globefindpro.com/products/104185.html

-

Laser Welder PB300CE

Laser Welder PB300CE

-

Laser Cutter CS0605-100

Laser Cutter CS0605-100

-

3D Laser Engraver INSIDER-I

3D Laser Engraver INSIDER-I

-

Lamp-Pump YAG Laser Marker YAG-T50

Lamp-Pump YAG Laser Marker YAG-T50

-

Large Format CNC Plasma Cutting Machine

Large Format CNC Plasma Cutting Machine

-

CNC Laser-Like Plasma Cutting Machine

CNC Laser-Like Plasma Cutting Machine

-

Lamp-Pump YAG Laser Marker YAG-T80C

Lamp-Pump YAG Laser Marker YAG-T80C

-

Economic CNC Plasma Cutting Machine (Tabletop Split Type)

Economic CNC Plasma Cutting Machine (Tabletop Split Type)

-

CNC Oxy-Fuel Cutting Machine

CNC Oxy-Fuel Cutting Machine

-

Laser Welder MOLD 301

Laser Welder MOLD 301

-

CNC Plasma Pipe Cutting Machine

CNC Plasma Pipe Cutting Machine

-

Thin Metal Sheet Laser Cutter CS035F-50X 200X

Thin Metal Sheet Laser Cutter CS035F-50X 200X