Press Brake, WE67K Series

Features This press brake features a fully welded structure with a high strength and rigidity. Main components use an ANSYS FEM (Finite Element Analysis) to ensure machine reliability and accuracy. The main oil cylinders on both sides use a different control method than traditional bending machines do. This equipment uses a closed-loop control method comprised of an electro-hydraulic servo valve and grating ruler imported from Germany. The slide block features an excellent position feedback accuracy, supporting stable operation. The slide block bending angle and position are both recorded to ensure uniformity. Functional parts in the back gauge are all imported to ensure the accuracy. We also use a multi-axis back gauge to improve the gauging precision according to customer needs. The hydraulic system uses an integrated control system imported from Germany. It features a simple design, reducing the number of pipelines needed for operational stability. High-precision grating scales are installed on the C frame on both sides, therefore preventing any influence on the bending accuracy caused by deformation. The worktable supports hydraulic deflection compensation, allowing for an effective compensation for operational stability. The numerical control systems on the electro-hydraulic bending machines are imported from Italian ESA, Dutch DEL EM or Swiss CYBELEC, allowing for a number of functions, including bending angle programming and auto-correction, bending pressure adjustment, back gauge retraction and more. Technical Parameters

Optional Control System

DA-52S control system

6.4" LCD color display Maximum 4-axis control Quick programming ” Hot key” navigation Work table compensating winding control Toolings/materials/products warehouse 266MHz processor 64MB memory 30 upper dies and 30 lower dies Diagnostic program

DA-58T control system

Built-in PLC(Programmable Logic Controller) function 2D graphical touch screen programming mode 15" high resolution TFT color display Counting system of bending process Deflection compensation Servo and inverter control Y-axis controlling program Open loop, closed loop compound control algorithm USB interface Profile-58TL offline programming software

DA-66T control system

2D graphical touch screen programming mode 3D graphics display 17" high resolution TFT color display CNC control with Microsoft Windows USB external interface Multitask operating system Angle positioning sensor

Standard Configurations

Main motor from Siemens

Ball screw and linear rail from Taiwan HIWIN

Electrical system from French SCHNEIDER

Oil pump from Sunny

Manifold valve from REXROTH

Clamping system

Sectioned CNC tooling

Front arms

Servo motor

Foot switch

Dual guide rails back gauge crossbar

Grating ruler

Mechanical compensation

Optional

Light curtain protection

Laser protection

Multi-axis back gauge control mechanism

Multi-function foot switch

Cooling fan

| Nominal force | KN | 1000 | 2500 | |

| Table length | mm | 3200 | 3200 | |

| Distance between frames | mm | 2650 | 2670 | |

| Throat depth | mm | 340 | 360 | |

| Ram stroke | mm | 160 | 250 | |

| Stroke adjustment | mm | 40 | 100 | |

| Max. open height | mm | 450 | 480 | |

| Ram speed | No load | mm/s | 60 | 60 |

| Full load | mm/s | 8 | 12 | |

| Return | mm/s | 66 | 66 | |

| Main power | Model | Y132M-4 | Y160M-4 | |

| Power | KW | 7.5 | 18.5 | |

| Speed | r/min | 1440 | 1440 | |

| Servo motor for back gauge | Model | HN160T-M050C3A-6 | HN160T-M050C3A-6 | |

| Power | KW | 1 | 1 | |

| Speed | r/min | 2200 | 2200 | |

| Gear pump | Model | NT2-G16F | NT2-G40F | |

| Pressure | Mpa | 25 | 28 | |

| Flow rate | ml/r | 16 | 40 | |

| Outline dimensions | Length | mm | 3200 | 3200 |

| Width | mm | 1400 | 1800 | |

| Height | mm | 2500 | 2850 | |

| Max. working pressure | Mpa | 25 | 28 | |

Optional Control System

DA-52S control system

6.4" LCD color display Maximum 4-axis control Quick programming ” Hot key” navigation Work table compensating winding control Toolings/materials/products warehouse 266MHz processor 64MB memory 30 upper dies and 30 lower dies Diagnostic program

DA-58T control system

Built-in PLC(Programmable Logic Controller) function 2D graphical touch screen programming mode 15" high resolution TFT color display Counting system of bending process Deflection compensation Servo and inverter control Y-axis controlling program Open loop, closed loop compound control algorithm USB interface Profile-58TL offline programming software

DA-66T control system

2D graphical touch screen programming mode 3D graphics display 17" high resolution TFT color display CNC control with Microsoft Windows USB external interface Multitask operating system Angle positioning sensor

Standard Configurations

Main motor from Siemens

Ball screw and linear rail from Taiwan HIWIN

Electrical system from French SCHNEIDER

Oil pump from Sunny

Manifold valve from REXROTH

Clamping system

Sectioned CNC tooling

Front arms

Servo motor

Foot switch

Dual guide rails back gauge crossbar

Grating ruler

Mechanical compensation

Optional

Light curtain protection

Laser protection

Multi-axis back gauge control mechanism

Multi-function foot switch

Cooling fan

Scan QR to Read

Links:https://www.globefindpro.com/products/10445.html

Links:https://www.globefindpro.com/products/10445.html

Recommended Products

-

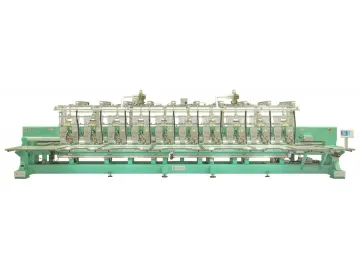

Idea-S Mini Commercial Series

Idea-S Mini Commercial Series

-

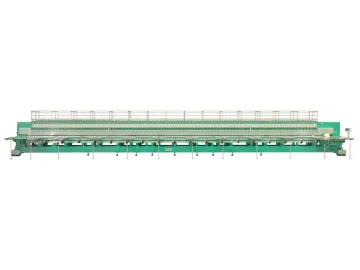

HE Flat Machine Series

HE Flat Machine Series

-

Mix-PTS Series

Mix-PTS Series

-

Four Rollers Plate Bending Machine

Four Rollers Plate Bending Machine

-

Accessories

Accessories

-

Plate Bending Machine for Shipyard

Plate Bending Machine for Shipyard

-

Nonwoven Cleanroom Wipes

Nonwoven Cleanroom Wipes

-

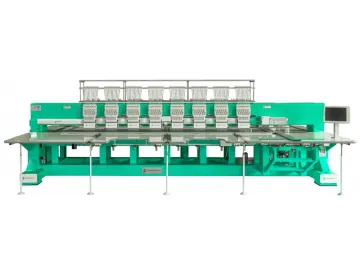

HP Flat Machine Series

HP Flat Machine Series

-

DE Flat Machine Series

DE Flat Machine Series

-

Asymmetrical Plate Bending Machine

Asymmetrical Plate Bending Machine

-

TES Chenille Machine Series

TES Chenille Machine Series

-

HM Flat Machine Series

HM Flat Machine Series

Hot Products