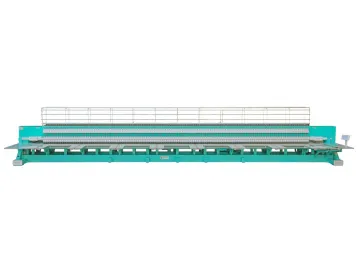

QC11 Series Hydraulic Guillotine Shear, Metal Shearing Machine

Hydraulic Sheet Metal Shear, Metal Plate Cutting Shear

Features This metal shearing machine features a steel welded structure to eliminate internal stress in order to maintain an excellent rigidity and stability. It uses an integrated hydraulic system to maintain its reliability. The three-point-support rolling guide reduces cutting defects to improve cutting quality. The blade gap is adjusted using the handwheel, which supports a quick and precise adjustment. Four blade edges are all available for cutting, ensuring high working efficiency. The shear angle is adjustable to reduce sheet distortion. The upper tool holder features an inward tilt structure, which is convenient for blanking, thus enhancing the cutting precision. This machine carries out sectioned cutting and shadow cut lines for a better precision. The back gauge is controlled by the CNC control system. Rear supporting material positioning platform (optional) Technical Parameters

Optional Control System

MD11-1 control system

Simple and easy operation 10-step programs Manual changing and adjustment of the plates Auto-retraction function Parameter setting and modification

E21S control system

Back gauge control system Automatic positioning Dual programmable digital output 40 Programs stored, 25 steps per program Back gauge retract function One-click backup and restoration mm/inch, English operation interface

Standard Configurations

Main motor from Siemens

Ball screw and linear rail from Taiwan HIWIN

Electrical system from French SCHNEIDER

Oil pump from Sunny

Manifold valve from REXROTH

Tube fittings and tube adapters

Motor

Front arms

Optional

Light curtain protection

Rear supporting material positioning platform

Features This metal shearing machine features a steel welded structure to eliminate internal stress in order to maintain an excellent rigidity and stability. It uses an integrated hydraulic system to maintain its reliability. The three-point-support rolling guide reduces cutting defects to improve cutting quality. The blade gap is adjusted using the handwheel, which supports a quick and precise adjustment. Four blade edges are all available for cutting, ensuring high working efficiency. The shear angle is adjustable to reduce sheet distortion. The upper tool holder features an inward tilt structure, which is convenient for blanking, thus enhancing the cutting precision. This machine carries out sectioned cutting and shadow cut lines for a better precision. The back gauge is controlled by the CNC control system. Rear supporting material positioning platform (optional) Technical Parameters

| Model | Cutting thickness(mm) | Cutting width (mm) | Throat depth(mm) | Back gauge range(mm) | Shear angle(。) | Strokes(min-1) | Motor power(KW) | Overall dimensions(mm) | |

| 6×2500 | 6 | 2500 | 80 | 500 | 0.5-1.3 | 14 | 7.5 | 3100×1725×1960 | |

| 6×3200 | 6 | 3200 | 80 | 500 | 0.5-1.3 | 12 | 7.5 | 3650×1750×1980 | |

| 6×4000 | 6 | 4000 | 80 | 500 | 0.5-1.3 | 10 | 7.5 | 4650×1780×2075 | |

| 6×5000 | 6 | 5000 | 80 | 500 | 0.5-1.3 | 8 | 7.5 | 5650×183×2250 | |

| 8×2500 | 8 | 2500 | 80 | 500 | 0.5-1.3 | 14 | 7.5 | 3100×1725×1960 | |

| 8×3200 | 8 | 3200 | 80 | 500 | 0.5-1.3 | 12 | 7.5 | 3850×1750×1980 | |

| 8×4000 | 8 | 4000 | 80 | 500 | 0.5-1.3 | 10 | 7.5 | 4650×1850×2075 | |

| 8×5000 | 8 | 5000 | 80 | 500 | 0.5-2 | 7 | 15 | 5805×2000×2500 | |

| 10×2500 | 10 | 2500 | 120 | 500 | 0.5-2.3 | 10 | 15 | 3195×1800×2210 | |

| 10×3200 | 10 | 3200 | 120 | 500 | 0.5-2.3 | 8 | 15 | 3895×1800×2240 | |

| 10×4000 | 10 | 4000 | 120 | 500 | 0.5-2.3 | 6 | 15 | 4695×1930×2275 | |

| 10×5000 | 10 | 5000 | 120 | 500 | 0.5-2.3 | 5 | 15 | 5905×2115×2715 | |

| 12×2500 | 12 | 2500 | 120 | 500 | 0.5-2.3 | 10 | 15 | 3195×1800×2210 | |

| 12×3200 | 12 | 3200 | 120 | 500 | 0.5-2.3 | 8 | 15 | 3895×1800×2240 | |

| 12×4000 | 12 | 4000 | 120 | 500 | 0.5-2.3 | 6 | 15 | 4710×1950×2485 | |

| 12×5000 | 12 | 5000 | 120 | 500 | 0.5-2.3 | 5 | 18.5 | 5905×2115×2800 | |

| 16×2500 | 16 | 2500 | 120 | 500 | 0.5-2.3 | 8 | 15 | 3215×1880×2340 | |

| 16×3200 | 16 | 3200 | 120 | 500 | 0.5-2.3 | 7 | 15 | 3915×1880×2445 | |

| 16×4000 | 16 | 4000 | 120 | 500 | 0.5-2.3 | 6 | 15 | 4715×1950×2590 | |

| 16×5000 | 16 | 5000 | 120 | 500 | 0.5-3 | 5 | 22 | 6000×2300×3000 | |

| 20×2500 | 20 | 2500 | 120 | 500 | 0.5-3 | 6 | 22 | 3215×1890×2465 | |

| 20×3200 | 20 | 3200 | 120 | 500 | 0.5-3 | 5 | 30 | 4120×1890×2780 | |

| 20×4000 | 20 | 4000 | 120 | 500 | 0.5-3 | 4 | 30 | 4925×2150×2900 | |

Optional Control System

MD11-1 control system

Simple and easy operation 10-step programs Manual changing and adjustment of the plates Auto-retraction function Parameter setting and modification

E21S control system

Back gauge control system Automatic positioning Dual programmable digital output 40 Programs stored, 25 steps per program Back gauge retract function One-click backup and restoration mm/inch, English operation interface

Standard Configurations

Main motor from Siemens

Ball screw and linear rail from Taiwan HIWIN

Electrical system from French SCHNEIDER

Oil pump from Sunny

Manifold valve from REXROTH

Tube fittings and tube adapters

Motor

Front arms

Optional

Light curtain protection

Rear supporting material positioning platform

Scan QR to Read

Links:https://www.globefindpro.com/products/10453.html

Links:https://www.globefindpro.com/products/10453.html

Recommended Products

-

Plate Bending Machine for Tanker

Plate Bending Machine for Tanker

-

Q11 Series Mechanical Shear, Sheet Metal Shearing

Q11 Series Mechanical Shear, Sheet Metal Shearing

-

Universal Plate Bending Machine

Universal Plate Bending Machine

-

Mix-PCS Series

Mix-PCS Series

-

Disposable Cleaning Cloths

Disposable Cleaning Cloths

-

HS Flat Machine Series

HS Flat Machine Series

-

Tandem Press Brake

Tandem Press Brake

-

Plate Bending Machine for Shipyard

Plate Bending Machine for Shipyard

-

Accessories

Accessories

-

Four Rollers Plate Bending Machine

Four Rollers Plate Bending Machine

-

Mix-PTS Series

Mix-PTS Series

-

HE Flat Machine Series

HE Flat Machine Series