Evaporative Pattern Casting Technology and Equipment

EvaporativePattern Casting Technology and Equipment

Description

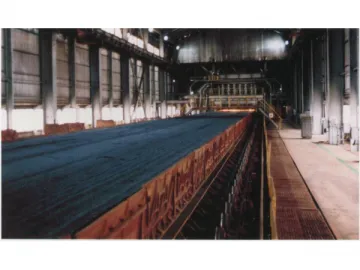

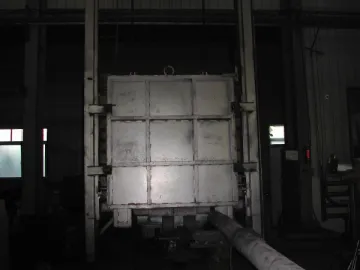

As an environmentally friendly and energy efficient technology, the evaporativepattern casting technology and equipment is a revolution in the history ofcasting technology, and honored as the new high technology of the 21st century. According to this new technology, themold is made from foamed plastics. The mold is coated by special paint and thenburied in dry sand to form a shaped mold. Metal liquid is then poured under the state ofnegative pressure. When the metal liquidis cooled and solidified, the castings will be completed.

Features

Castingsmade by the EPC technology and equipment are of compact organization, highprecision and smooth surface. The EPC technology has the advantage of strongadaptability so that it can manufacture components of various sizes. The technology features low cost, high workefficiency, high productivity and good economic returns. The PLC technology is environmentally friendlyas it discharges very little waste.

Our companyowns advanced EPC technology, manufacturing ability of corollary equipment andrich experience in the site commissioning. We can provide customers with many kinds of serviceconcerning the EPC project, such as the feasibility study, engineering design,equipment manufacturing, special paint, manufacturing technology and technicalconsultation. The corollary equipmentincludes pre-foam machine, molder, three dimensional jolt table, vacuum unitand PLC control system. The corollaryequipment has an attractive appearance, reliable function and low price.

| Model of the Complete Equipment | SZZ-A | SZZ-AI | SZZ-AII | SZZ-AIII | SZZ-AIV | SZZ-AV |

| Occupation of Land (m2) | 30 | 40 | 50 | 120 | 150 | 180 |

| Power (KW) | 15 | 25 | 40 | 80 | 120 | 150 |

| Applicable Length (t/year) | 500 | 500-1000 | 1000-2000 | 2000-3000 | 3000-3000 | 5000-10000 |

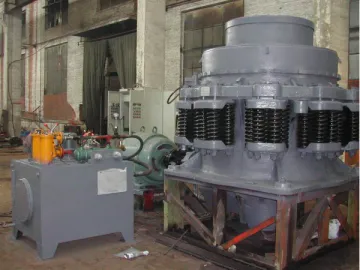

Yate is a major manufacturer of evaporative pattern castingtechnology and equipment, based in China. We offer different kinds of products includingevaporative pattern casting technology and equipment, ball mill, sinteringmachine, copper bush centrifugal casting machine, and blast furnace. Our products are high quality andcompetitively priced. Our full chain ofmanufacturing mold, hydraulic pressure testing machine and bitumen coatingmachine can be completed in China, even in one city. Our lowermanufacturing cost can save your purchasing cost. A more detailed description of our product isshown on the page.

Links:https://www.globefindpro.com/products/104942.html