Hydraulic Swing Beam Shear, QS12Y Series Deep Throat Type

Hydraulic Swing Beam Shear, QS12Y Series Deep Throat Type

Features

1. Like QC12Y hydraulic swing beam shear, QS12Y hydraulic swing beam shear also adopts steel welded construction.

2. It adopts an economical type CNC system which is specially designed for sheet metal equipment.

3. The utilization of imported ball screw and linear guideway helps ensure the positioning accuracy of the back gauge.

Applications

With a wide cutting capacity, the hydraulic swing beam shear can accommodate most sheet metal shearing applications in the industries of steel manufacturing, shipbuilding, automobile, container manufacturing, machinery manufacturing, and more.

Technical Specifications of Deep Throat Type Hydraulic Swing Beam Shear

QS12Y-6×2500 | QS12Y-6×4000 | QS12Y-8×3200 | QS12Y-8×4000 | QS12Y-12×3200 | ||

Cutting size(T×W) | 62500 | 64000 | 83200 | 84000 | 123200 | |

Shear angle | 1°30′ | 1°30′ | 1°30′ | 1°30′ | 2° | |

Strokes | Min-1 | ≥16 | ≥10 | ≥10 | ≥10 | ≥9 |

Adjusting range of backgauge | mm | 20-600 | 20-600 | 20-600 | 20-600 | 20-800 |

Throat depth | mm | 400 | 450 | 400 | 400 | 420 |

Main motor power | kW | 7.5 | 7.5 | 11 | 11 | 18.5 |

Net weight | kg | 5600 | 9000 | 7900 | 10500 | 12000 |

Overall dimensions(L×W×H) | mm | 315015001600 | 465019501700 | 388018301720 | 468019801780 | 400021001940 |

QS12Y-12×4000 | QS12Y-12×6000 | QS12Y-16×3200 | QS12Y-16×4000 | QS12Y-32×2500 | ||

Cutting size(T×W) | 124000 | 126000 | 163200 | 164000 | 322500 | |

Shear angle | 1°54′ | 2° | 2° | 2° | 3°30′ | |

Strokes | Min-1 | ≥8 | ≥4 | ≥8 | ≥7 | ≥4 |

Adjusting range of backgauge | mm | 20-800 | 20-1000 | 20-800 | 20-1000 | 20-1000 |

Throat depth | mm | 420 | 600 | 480 | 450 | 700 |

Main motor power | kW | 18.5 | 30 | 22 | 30 | 45 |

Net weight | kg | 14800 | 42000 | 15000 | 21500 | 33000 |

Overall dimensions(L×W×H) | mm | 480021001940 | 694030502600 | 403022702100 | 482024902300 | 355033002875 |

Main Material

Cast iron

Maintenance

1. Operate the hydraulic swing beam shear in strict accordance with operating instructions.

2. Before starting the machine, timely, accurately and quantitatively add lubricant to some parts according to the requirements of lubrication chart. The lubricant should be clean and contain no precipitation.

3. Keep the hydraulic swing beam shear clean and put anti-rust grease on machine parts which are unpainted.

4. Regularly replace or add grease lubricant to the bearings of the motor.

5. Carefully check the electrical part to ensure smooth, reliable operation.

6. Regularly check V-belt, handle, knob, button, etc. so that you can replace them timely if they are seriously worn out.

7. After work, add lubricant to the machine and clean it thoroughly.

8. The blades should be fastened and oiled regularly.

9. Avoid shear sheet metal that exceeds the rated pressure.

10. The hydraulic swing beam shear should only be operated by professional personnel.

11. Shut off the machine if the operator leaves.

Packaging

1. Wood packaging for export, according to customers’ specific suffocating requirements

2. Plywood packaging

Service

1. Our hydraulic swing beam shear comes with a one-year warranty, during which we offer spare parts free of charge.

2. We will not compensate loss if the problem is caused by improper operation or other human errors.

Links:https://www.globefindpro.com/products/105030.html

-

Hydraulic Guillotine Shear, QC11Y Series

Hydraulic Guillotine Shear, QC11Y Series

-

Electronic Energy Meter (Front Board Mounted Static KWH Meter)

Electronic Energy Meter (Front Board Mounted Static KWH Meter)

-

DDM100SCF DIN-rail Energy Meter, Multi-Tariff, 4 Pole/Modular

DDM100SCF DIN-rail Energy Meter, Multi-Tariff, 4 Pole/Modular

-

CNC Hydraulic Press Brake, WC67K Series Economic Type

CNC Hydraulic Press Brake, WC67K Series Economic Type

-

CNC Hydraulic Press Brake, WC67K Series Tandem Economic Type

CNC Hydraulic Press Brake, WC67K Series Tandem Economic Type

-

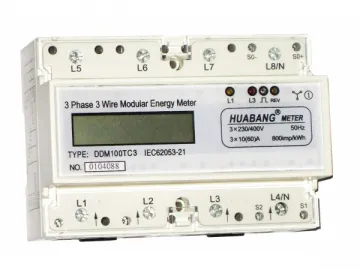

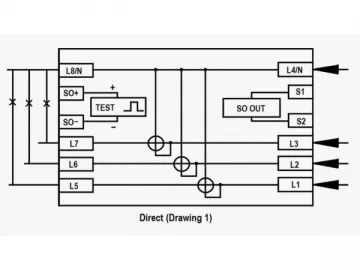

Three Phase Three Wire DIN-rail Active Energy Meter

Three Phase Three Wire DIN-rail Active Energy Meter

-

DDM100TCF Multi-Tariff DIN-rail Energy Meter, 7 Pole/Modular

DDM100TCF Multi-Tariff DIN-rail Energy Meter, 7 Pole/Modular

-

DDM100TR DIN-rail Energy Meter With Communication Port, 7 Pole/Modular

DDM100TR DIN-rail Energy Meter With Communication Port, 7 Pole/Modular

-

DDM65 DIN-rail Energy Meter, 2 Pole/Modular

DDM65 DIN-rail Energy Meter, 2 Pole/Modular

-

Hydraulic Press Brake, WC67Y Series

Hydraulic Press Brake, WC67Y Series

-

CNC Hydraulic Guillotine Shear, QC11K Series Economic Type

CNC Hydraulic Guillotine Shear, QC11K Series Economic Type

-

Planer Boring Milling Machine

Planer Boring Milling Machine