Injection Molding Machine B.SJ

Injection molding machine applies high reponsive proportional variable pump system to replace the traditionl 3-way proportionl valve control mode , thus to enable the high match of power betweem hydraulic out put and machine effective operation which avoids energy loss from high pressure throttle , flow , compared with normal constant pump drive machine the variable pump drive machine is able to save . in addtion , the machine less heating enables save of cooling water by 30% , debasing perheral noise and extension of service life hydraulic sealing part sand oil to minimize operation and maintenance cost and meanwhile to meet the strict international enviroment protective policy finally , the amount of the output increases obviously.

[4] Injection Molding Machine B•SJ

These products are widel used in cosmetics tube cap,toothpaste tube cap,pharmaceutical tube cap and food industries tube cap etc.

[4] Injection Molding Machine B•SJ

B·JS680×1 | |

A B C | |

(mm) | 26 30 34 |

(L/D) | 24 21 19 |

(cm3) | 66 88 113 |

(g) | 60 80 103 |

(oz) | 2.1 2.8 3.6 |

(g/s) | 75 82 86 |

(g/s) | 7.4 8.9 9.4 |

(Mpa) | 245 184 143 |

(r/min) | 255 |

(KN) | 680 |

(mm) | 275 |

(mm) | 310×310 |

(mm) | 320 |

(mm) | 120 |

(mm) | 75 |

(KN) | 33 |

(Mpa) | 16 |

(kW) | 9 |

(kW) | 5.2 |

(m) | 3.9×1.0×1.65 |

(t) | 2.5 |

Links:https://www.globefindpro.com/products/105513.html

-

Aluminum Plastic Laminated Tube Making Machine B.GLS-II

Aluminum Plastic Laminated Tube Making Machine B.GLS-II

-

Filling And Sealing Machine B.GF-J

Filling And Sealing Machine B.GF-J

-

High Power LED Floodlight

High Power LED Floodlight

-

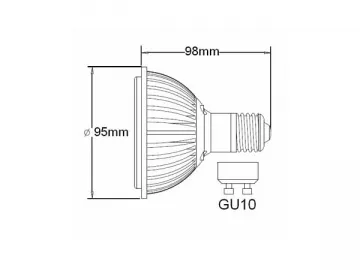

PAR30 LED Spotlight

PAR30 LED Spotlight

-

SMD Candle LED Light

SMD Candle LED Light

-

Spiral Steel Pipeline (Spiral Steel Pipe)

Spiral Steel Pipeline (Spiral Steel Pipe)

-

360° Candle LED Light

360° Candle LED Light

-

E27 LED Light Bulb

E27 LED Light Bulb

-

Pneumatic Filling Machine B.G

Pneumatic Filling Machine B.G

-

E27 LED Spotlight

E27 LED Spotlight

-

Filling And Sealing Machine B.GF-40

Filling And Sealing Machine B.GF-40

-

Aluminum Tube Extruder, RC150 Horizontal Cooling Type

Aluminum Tube Extruder, RC150 Horizontal Cooling Type