Aluminum Plastic Laminated Tube Making Machine B.GLS-II

B·GLS-II Aluminum-plastic Laminated Tube Machine was made on our first generation tube machine and advanced foreign technologies. It integrates with mechanical, electronic and pneumatic technologies. Compared with the similar one abroad, our machine has the advantages of little investment, high efficiency, low energy consumption, easy operation, stability and convenient maintenance. The machine can produce the aluminum-plastic laminated tubes in various specifications. High frequency welding is applied.The welded seamis firm and smooth.

The machine is composed of an automatic roll-releasing device, connecting platform, an automatic margin-cutting mechanism, an automatic tube forming device, a high frequency welding mechanism, the vertical and horizontal traction devices, an automatic synchronous revolving cutting mechanism and a computer control system.

[3] Aluminum Plastic Laminated Tube Making Machine B•GLS-II

These products are widel used in cosmetics tube,toothpaste tube,pharmaceutical tube and food industries tube and so on

[3] Aluminum Plastic Laminated Tube Making Machine B•GLS-II

:(Main Technical Parameters)

Power of The Main Machine | 2.2kW |

Motor Power of The Cutting Device | 1.0kW |

Power of High Frequency Welding | 15.0kW |

Power Supply | 380(220)v/50Hz |

Productivity | 120(pcs) /min |

Dimensions(L×W×H) | 5000×800×1800mm |

Weight | 2500kg |

Links:https://www.globefindpro.com/products/105514.html

-

Filling And Sealing Machine B.GF-J

Filling And Sealing Machine B.GF-J

-

High Power LED Floodlight

High Power LED Floodlight

-

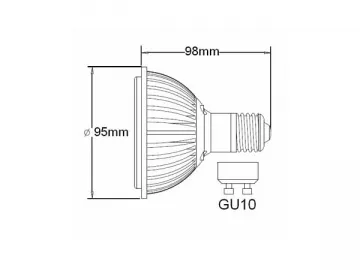

PAR30 LED Spotlight

PAR30 LED Spotlight

-

SMD Candle LED Light

SMD Candle LED Light

-

Spiral Steel Pipeline (Spiral Steel Pipe)

Spiral Steel Pipeline (Spiral Steel Pipe)

-

High Power LED Wall Washer

High Power LED Wall Washer

-

Injection Molding Machine B.SJ

Injection Molding Machine B.SJ

-

360° Candle LED Light

360° Candle LED Light

-

E27 LED Light Bulb

E27 LED Light Bulb

-

Pneumatic Filling Machine B.G

Pneumatic Filling Machine B.G

-

E27 LED Spotlight

E27 LED Spotlight

-

Filling And Sealing Machine B.GF-40

Filling And Sealing Machine B.GF-40