Plastic Injection Molding Machine B.ZTN-II And Mould

B.ZJN-II Plastic injection & forming machine is developed based on our second generation injection machine and advanced foreign technologies.its double-mould alternative forming way gives it high work efficiency..when the worker opration the machine, it need two hands press the joint mold at the same time. Avoiding the hands touch the middle of the mold. Secuing the safty of the people.

This machine ,safe and reliable.has the advantages of premolding on screw,material-input in a fixed quantity at a specific postion.the chief valve adopt doublt proportion, stress match with equalyt,precision in low pression.the whole process is fluency and excellent.control temperature and jet pression in different sectors. Firing rate and stepless adjustment. With the function of in or out which it will more convinient of adjust the mold and cleanning the pipe.large mould-lock power ,smooth mould moviing ,electric and pneumatic interlocking .small taken installation space,convenient assembing and disassembling of the moulds..

Shouldder-injection mould : the diameter of tube is 12.7mm-60mm.with ellipse and round shape ,we can manufacture it according ot the customer’s needs and also can make screw shape.

[6] Plastic Injection Molding Machine B•ZTN-II And Mould

These products are widel used in cosmetics tube,toothpaste tube,pharmaceutical tube and food industries tube ,etc.

[6] Plastic Injection Molding Machine B•ZTN-II And Mould

Main Technical Parameters:

Power of The Main Machine | 5.5KW |

Heating Power | 4.7KW |

Casting Quantity | 115cm3 |

Power Supply | 128MPa |

Mould-Lock Power | 450KN |

Mould-Open Power | 150KN |

Production Capacity | 25-32pcs/min |

Dimension | 1500×1600×2500mm |

Weight | 1800kg |

Links:https://www.globefindpro.com/products/105526.html

-

Dimmable LED Spotlight

Dimmable LED Spotlight

-

Dimmable LED Light Bulb

Dimmable LED Light Bulb

-

Tube Holing, Sealing & Capping Machine B.ZFG-II

Tube Holing, Sealing & Capping Machine B.ZFG-II

-

PAR38 LED Spotlight

PAR38 LED Spotlight

-

PAR56 LED Spotlight

PAR56 LED Spotlight

-

Plastic Injection Molding Machine B.ZT-II And Mould

Plastic Injection Molding Machine B.ZT-II And Mould

-

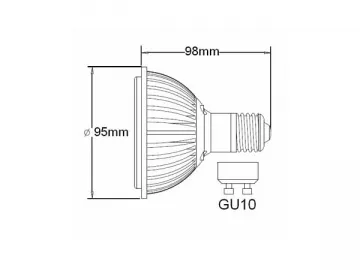

GU10 LED Spotlight

GU10 LED Spotlight

-

High Power LED Wall Washer

High Power LED Wall Washer

-

Spiral Steel Pipeline (Spiral Steel Pipe)

Spiral Steel Pipeline (Spiral Steel Pipe)

-

SMD Candle LED Light

SMD Candle LED Light

-

PAR30 LED Spotlight

PAR30 LED Spotlight

-

High Power LED Floodlight

High Power LED Floodlight