Plastic Injection Molding Machine B.ZT-II And Mould

Its double-mould alternative forming way gives it high work efficiency. This machine, safe and reliable, has the advantages of pre-molding on screw, material-input in a fixed quantity at a specific position, all-hydraulic mould-closure with high and low speed, large mould-lock power, smooth mould moving, electric and pneumatic interlocking, small taken installation space, convenient assembling and disassembling of the moulds.

Shoulder-injection mould: diameter of tube is 12.7mm—60 mm, with ellipse and round shape, manufacture it according to the customers’ need and also can make screw shape.

[5] Plastic Injection Molding Machine B•ZT-II And Mould

These products are widel used in cosmetics tube,toothpaste tube,pharmaceutical tube and food industries tube and so on

[5] Plastic Injection Molding Machine B•ZT-II And Mould

Main Technical Parameters:

Power of The Main Machine | 5.5KW |

Heating Power | 3.5KW |

Casting Quantity | 63cm3 |

Power Supply | 136MPa |

Mould-Lock Power | 400KN |

Mould-Open Power | 100KN |

Production Capacity | 22-24pcs/min |

Dimension | 2300×1700×2800mm |

Weight | 1300kg |

Links:https://www.globefindpro.com/products/105532.html

-

G24 LED Corn Bulb

G24 LED Corn Bulb

-

High Power Candle LED Light

High Power Candle LED Light

-

RGB LED Wall Washer

RGB LED Wall Washer

-

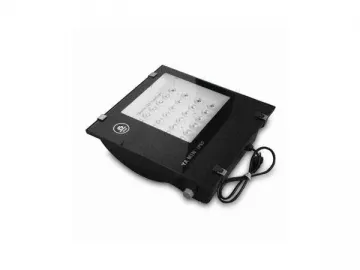

RGB LED Floodlight

RGB LED Floodlight

-

UHP Waterjet Cleaning System

UHP Waterjet Cleaning System

-

Concrete Cutting

Concrete Cutting

-

PAR56 LED Spotlight

PAR56 LED Spotlight

-

PAR38 LED Spotlight

PAR38 LED Spotlight

-

Tube Holing, Sealing & Capping Machine B.ZFG-II

Tube Holing, Sealing & Capping Machine B.ZFG-II

-

Dimmable LED Light Bulb

Dimmable LED Light Bulb

-

Dimmable LED Spotlight

Dimmable LED Spotlight

-

Plastic Injection Molding Machine B.ZTN-II And Mould

Plastic Injection Molding Machine B.ZTN-II And Mould