Concrete Cutting

1. UHP waterjet technology for concrete removal

According to the different requirements, UHP waterjet cutting can achieve different effects.

1) Low-pressure state

If the pressure is below 150MPa, surface concrete of up to 25 mmdepth can be removed. The steel structure is not exposed.

2) High-pressure state

When water pressure is 280MPa, the waterjet machine together with proper feeding device could penetrate through the concrete layer, and make steel structure completely exposed.

Great advantages

1. Compared to traditional methods, UHP waterjet cutting has faster cutting speed and higher efficiency.

2. It can create irregular and rough surface, which results in better adhesion of the refilling materials.

3. It can remove the concrete according to the required thickness.

4. Some concrete removed can be recycled next time, which really saves money.

5. The steel structure is remained.

6. No surface leakage is generated.

7. No extra damage is created by shocks during the operation.

8. UHP waterjet machine can effectively lower the noise.

9. Little wastes are produced during cutting process.

10. Automatic robot or mechanical system can greatly reduce labor intensity.

2. Movable UHP waterjet cutting system

1. Movable UHP waterjet cutting system is convenient to transport. With pressure up to 280 Mpa, water jet with abrasives can demolish both external concrete and steel structure inside.

2. Waterjet cutting will not cause explosion or fire, and generate no heat. Hence, problem like distortion is eliminated. Safe operation and long equipment service life are also ensured.

3. Movable UHP waterjet cutting system is able to cut almost all the materials. It can be used in the following circumstances,

a) Places having risks of explosion or fire

b) Super thick materials

c) Composite materials, steel and concrete structure

d) Infusible materials

3. Construction method

According to the level of automation, there are three main types

1. Hand-hold cutter

It is small and suitable to places with narrow space. During cutting operation, it will cause backflow and require high labor intensity.

2. No backflow hand-hold cutter

The cutter is placed on a bracket. All the operations are completed manually. Hence, it can avoid the effect of the backflow to operator.

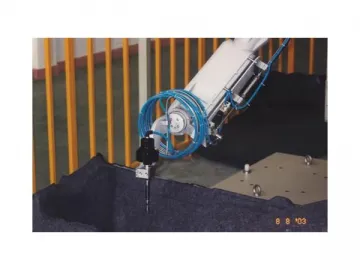

3. Computer controlled robot water cutting system

It can greatly improve the working efficiency. However, it is expensive.

Ultra high pressure pump

UHP pump is the key component of the cutting system, which is used to generate ultra high pressure water. Generally, the system parameters should be adjusted in accordance with the actual application. For cleaning application, users mainly adjust water flow, and the water pressure is about 150 Mpa. For cutting application, users mainly adjust pressure, which is usually 280 Mpa, and the water flow is about 201 pm.

4. Our solution

We at DARDI provide hand-hold cutter and movable cutting device to cut concrete. An automatic sand feeding device ensures continuous sand supply, which enables the cutting machine to consistently work for a long time. Our waterjet cutting machine can be used for horizontal and vertical cutting, meeting different cutting requirement.

DARDI’s DTPS16030 UHP waterjet cutting system is compact but powerful. It provides waterjet with pressure up to 280 Mpa. Its max water flow is up to 23 L/Min. Because of its small size, it can be carried by a car and driven by a diesel engine.

Links:https://www.globefindpro.com/products/105542.html

-

Automobile Manufacturing

Automobile Manufacturing

-

Pile Drilling SSAW Steel Pipe

Pile Drilling SSAW Steel Pipe

-

Oil Casing Steel Pipe (Seamless Pipe)

Oil Casing Steel Pipe (Seamless Pipe)

-

Metal Processing

Metal Processing

-

Glass Processing

Glass Processing

-

UHP Waterjet Technology

UHP Waterjet Technology

-

UHP Waterjet Cleaning System

UHP Waterjet Cleaning System

-

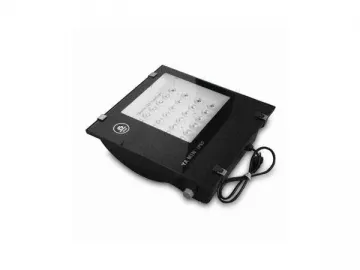

RGB LED Floodlight

RGB LED Floodlight

-

RGB LED Wall Washer

RGB LED Wall Washer

-

High Power Candle LED Light

High Power Candle LED Light

-

G24 LED Corn Bulb

G24 LED Corn Bulb

-

Plastic Injection Molding Machine B.ZT-II And Mould

Plastic Injection Molding Machine B.ZT-II And Mould