Automobile Manufacturing

Automobile Manufacturing

DARDI’s waterjet cutting machine has wide applications in the automobile manufacturing industry. Waterjet cutting is the ideal way to make automobile’s internal ornament. This is because high pressure waterjet cutting has many advantages compared to traditional methods. For example, waterjet cutting is more environmentally friendly because no toxic gas or industrial pollutant is produced during cutting process. As no heat is generated, thermal deformation is eliminated. In addition, it leaves better finish on the cut edge. Hence, all these features make waterjet cutting machinery warmly welcomed.

Applications

Due to rapid development of China’s rail transit industry, stainless steel, aluminum alloy and composite materials have been widely used in making railway vehicles over recent years. Waterjet cutting machine is an ideal tool to process these above mentioned materials.

Typically, our waterjet cutter is suitable for

(1) Railway vehicle body structural parts, made by stainless and aluminum alloy

(2) Bogie, made by steel and aluminum alloy

(3) Interior ornament, made by aluminum alloy, stainless steel and composite materials,

(4) Ventilation system, made by stainless steel,

(5) Signs, made by copper and aluminum.

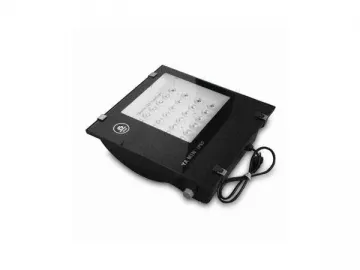

DARDI International Corporation is an experienced waterjet cutting machine manufacturer which has been dedicated to developing and producing superior waterjet cutting machinery. With reliable quality and easy operation, our waterjet cutters are very popular with customers from the automobile industry. Especially, ourDCM robot water cutting systembecomes the product of choice for interior ornament cutting.

This picture shows ourrobot water cutting systempurchased by GUANGZHOU Honda. It is cutting car’s interior ornament. ()

If you have any need of our products, please feel free to contact us.

Links:https://www.globefindpro.com/products/105545.html