Metal Processing

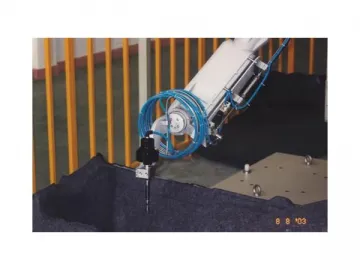

Characteristics of UHP waterjet cutting machine

1. DARDI waterjet cutting machine has a wide range of applications. It can cut nearly any materials, such as stainless steel, sheet steel, copper, aluminum, reinforced glass, stone, general glass, ceramics, plastic and composite materials, and so on.

2. UHP waterjet cutting will not generate heat. Thus, no heat effect and its related deformation are caused.

3. With assistance of computer technology and digital control technique, water jet cutter becomes the ideal tool for curve cutting and drilling tasks. No mould is needed. Thus, it provides great flexibility during its processing. It is also fast and easy to operate.

4. DARDI’s UHP waterjet cutting machine is designed to make the kerf as small as possible to save materials.

5. The cutting surface is smooth and the cutting quality is great. The waterjet cutter reduces or eliminates the need for secondary processing.

6. No pollutant is generated. Hence, our waterjet cutting machine is environment friendly.

Typical metal processing applications of UHP waterjet cutting machine

1. Decoration and ornament

2. Pressure container

3. Advertisement sign

4. Chassis, electrical cabinet

5. Mechanical machinery, like paper making equipment, fabric making machine, construction equipment

6. Aerospace, automobile manufacturing, etc.

DARDI International offers our customers CNC gantry waterjet cutting machine and CNC cantilever waterjet cutting machine, which come in different models. For more information, please click on the related webpage, or you can contact us directly.

Links:https://www.globefindpro.com/products/105549.html

-

Glass Processing

Glass Processing

-

UHP Waterjet Technology

UHP Waterjet Technology

-

Aerospace Manufacturing

Aerospace Manufacturing

-

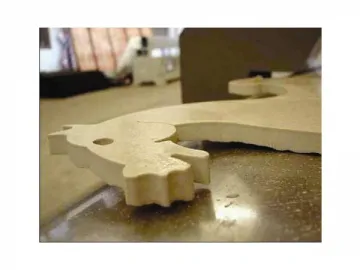

Stone and Ceramic Processing

Stone and Ceramic Processing

-

ERW Oil Casing Steel Pipe

ERW Oil Casing Steel Pipe

-

Low Pressure Fluid ERW Steel Pipe

Low Pressure Fluid ERW Steel Pipe

-

Oil Casing Steel Pipe (Seamless Pipe)

Oil Casing Steel Pipe (Seamless Pipe)

-

Pile Drilling SSAW Steel Pipe

Pile Drilling SSAW Steel Pipe

-

Automobile Manufacturing

Automobile Manufacturing

-

Concrete Cutting

Concrete Cutting

-

UHP Waterjet Cleaning System

UHP Waterjet Cleaning System

-

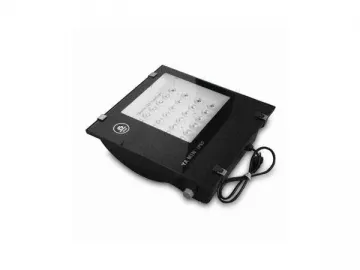

RGB LED Floodlight

RGB LED Floodlight