Stone and Ceramic Processing

Stone and Ceramic Processing

UHP waterjet cutting is increasingly used in many industries, especially stone and ceramic processing industry. Utilizing waterjet cutting has the following advantages,

1) Kerfs are smooth. Cutting performance is excellent. In addition, waterjet cutting will leave a nice finish on the cut edge.

2) Waterjet cutting machine has high cutting accuracy, which can be 0.1 mm. Hence, it is suitable to make mural or picture puzzle.

3) The cutting efficiency is high. Besides, the products produced by our equipment are interchangeable.

4) Little noise and dust caused during waterjet cutting process improves work environment.

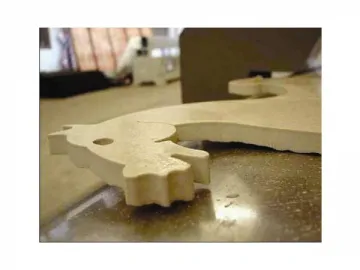

Some Typical Cases

The waterjet cutting machine is commonly used in the manufacturing of large ceramic murals, pottery screen, parquet floor, bathroom countertop, stone-made furniture, etc. Take parquet floor as an example. Using a waterjet cutter to make parquet floor can greatly improve efficiency and reduce labor cost. In addition, 40 % of materials costs are saved, because plenty of wastes can be recycled. The price of finished parquet floor is nearly 20 times the price of waste materials. That is why our customers can get back their original investment in 3 months.

In order to suit customers’ stone and ceramic processing requirements, we provide two types of plane waterjet cutting machine, including CNC gantry waterjet cutting machine and CNC cantilever waterjet cutting machine. Our products are CE compliant and have obtained more than 20 patents. For more detailed information, please click on the specific product page.

Links:https://www.globefindpro.com/products/105555.html

-

ERW Oil Casing Steel Pipe

ERW Oil Casing Steel Pipe

-

Low Pressure Fluid ERW Steel Pipe

Low Pressure Fluid ERW Steel Pipe

-

General Flow Spiral Steel Pipe

General Flow Spiral Steel Pipe

-

Construction Seamless Steel Pipe

Construction Seamless Steel Pipe

-

Fluid Steel Pipe (Seamless Pipe)

Fluid Steel Pipe (Seamless Pipe)

-

Boiler Steel Pipe (Seamless Pipe)

Boiler Steel Pipe (Seamless Pipe)

-

Aerospace Manufacturing

Aerospace Manufacturing

-

UHP Waterjet Technology

UHP Waterjet Technology

-

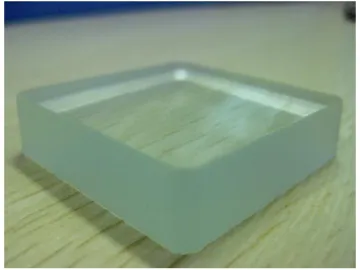

Glass Processing

Glass Processing

-

Metal Processing

Metal Processing

-

Oil Casing Steel Pipe (Seamless Pipe)

Oil Casing Steel Pipe (Seamless Pipe)

-

Pile Drilling SSAW Steel Pipe

Pile Drilling SSAW Steel Pipe