DCM Robot Water Cutting System

DCM Robot Water Cutting System

With rapid development of ultra high pressure waterjet cutting and robotic technology, a novel device is invented for cutting and processing automobile inner ornament, like canopy, carpet and instrument panel. This is robot water cutting system. Compared with traditional methods, this system has many advantages.

1. Smooth cutting edge

2. Fast cutting speed

3. Accurate cutting size

4. Consistent cutting quality

5. Environment friendly.

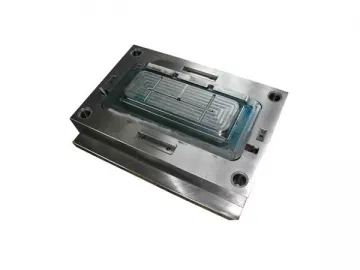

DARDI International Corporation is a leading robot water cutting system manufacturer in China. The product showed here is our DCM robot water cutting system, which is an ideal device for processing automobile inner ornament. This device consists of two main parts. For the robot part, we use YASKAWA UP-20MN, a 6-axis cutting robot. We utilize an ultra high pressure water cutting device as the cutting part. Our robot water cutting system is reliable, quality built, efficient and easy to operate. In addition, specialized mould is equipped to position and fix the object. Different moulds are offered to satisfy objects in diverse sizes. As a result, our product is very popular in the automobile industry.

Ever since the establishment of our company, we have constantly adopted new technologies in producing our products. Due to our consistent efforts, we are able to provide customers with top quality waterjet products, including plane waterjet cutting machine, ultra high pressure waterjet pump, UHP waterjet cleaning system, and more. If you are in need of an ideal DCM robot water cutting system, please feel free to contact us.

Links:https://www.globefindpro.com/products/105587.html

-

Pallet Mould

Pallet Mould

-

Electric Appliances Mould

Electric Appliances Mould

-

UHP Waterjet Cleaning System (Intensifier)

UHP Waterjet Cleaning System (Intensifier)

-

Connector Part Mold

Connector Part Mold

-

Refrigerator Parts Mold

Refrigerator Parts Mold

-

Air Conditioner Part Mold

Air Conditioner Part Mold

-

Dustbin mould

Dustbin mould

-

Excel Waterjet Cutting Machine

Excel Waterjet Cutting Machine

-

Beer Crate Mould

Beer Crate Mould

-

CNC Grinding Machine

CNC Grinding Machine

-

Drainage Fitting Mould

Drainage Fitting Mould

-

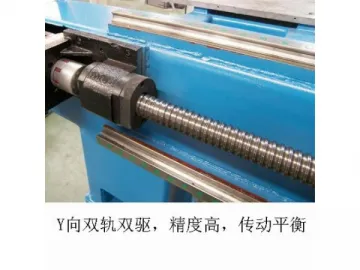

CNC Waterjet Cutting Table, DWJ30 Gantry Type

CNC Waterjet Cutting Table, DWJ30 Gantry Type