Welding Manipulator

WeldingManipulator

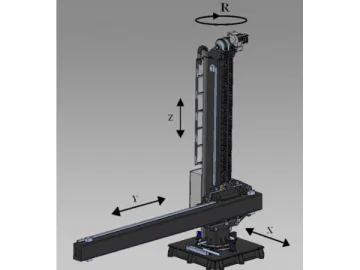

Manipulator

Our company is a famous welding machine manufacturerinvolved in the production of beam columns and cantilevers that are robustlyand precisely constructed to offer firm support for precision weldingapplications. Our beam column and cantilever is able to reach within smallinternal diameters as well as cover the outer surfaces of big diameters forboth circumferential and longitudinal welding of joints. We offer three typesof welding manipulators for your choice: all-position,fixed and fixed rotating manipulators. Upon request, different functions suchas tracking, monitoring and solder recycling, could be attached to our weldingmanipulators.

Features

1. This welding manipulator is made up of acolumn, a boom, a guide holder and a trolley.

2. A brake motor is fitted to the column, which works to achieve stable andsmooth positioning of the boom.

3. There is a row of security holes on the column and a safety pin on the guideholder. The safety pin would thrust into the hole when the chain breaks inorder to avoid serious accidents.

4. The lower part is connected to the foundation with a pivoting support. Itcarries out smooth and stable revolution and helps facilitate welding on manypieces simultaneously.

5. The boom is connected to the column with the guide holder, enabling verticaladjustment and horizontal extension.

6. A cross electrical regulator is also installed on the boom.

7. A stepless speed regulating converter is used tocontrol the extension of boom. Its performance is smooth and reliable. It comeswith a failure testing mechanism which triggers an alarm when failure occurs.

8. The speed reducer consists of a professional cycloidal-pinwheel and worm gear speed reducer.

9. It uses a totally sealed oil immersion lubricating method which helps keepoff dust, slag and other impurities.

10. The guide holder is of a box structure. Its upper part is connected to thelifting chain; the rear part is connected to the column with chain wheel; thefront part is connected to the boom.

11. Both the column and the boom adopt a V-shaped rail and are of high loadingcapacity.

Main Technical Parameters

| Type | JSL8080 | JSL4580 | JSL5060 | JSL3040 | JSL1235 |

| Hotizontal travel mm | 8000(Two byte) | 8000(Two byte) | 6000 | 4000 | 3500 |

| Vertical travel mm | 8000 | 4500 | 5000 | 3000 | 1200 |

| Rotating angle mm | ±180° | ±180° | ±180° | ±180° | Handle±360° |

| Rotating speed mm | 0.12 | 0.12 | 0.12 | 0.12 | / |

| Boom elevating speed m/min | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Boom forward speed m/min | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 | 0.12-1.2 |

| Table forward-backward speed m/min | 0.2-2 | 0.2-2 | 0.2-2 | 0.2-2 | Handle |

| Table rail distance mm | 2700 | 2000 | 2000 | 1500 | 1000 |

Links:https://www.globefindpro.com/products/106109.html

-

Acrylic Flower Fitting / Crystal Crafts ACF-24

Acrylic Flower Fitting / Crystal Crafts ACF-24

-

Jewellery / Crystal Crafts J-37

Jewellery / Crystal Crafts J-37

-

Jewellery / Crystal Crafts J-28

Jewellery / Crystal Crafts J-28

-

Crystal Deodorant Bottle / Crystal Crafts CDB-07

Crystal Deodorant Bottle / Crystal Crafts CDB-07

-

Crystal Deodorant Bottle / Crystal Crafts CDB-06

Crystal Deodorant Bottle / Crystal Crafts CDB-06

-

Water-cooled Diesel Engine

Water-cooled Diesel Engine

-

Jewellery / Crystal Crafts J-25

Jewellery / Crystal Crafts J-25

-

Acrylic Crystal Flower / Crystal Crafts ACF-23

Acrylic Crystal Flower / Crystal Crafts ACF-23

-

Crystal Pig / Crystal Crafts CP-11

Crystal Pig / Crystal Crafts CP-11

-

Jewellery / Crystal Crafts J-35

Jewellery / Crystal Crafts J-35

-

China knot / Crystal Crafts CK-32

China knot / Crystal Crafts CK-32

-

Jewellery / Crystal Crafts J-31

Jewellery / Crystal Crafts J-31