Continuous PU Sandwich Panel Machine

Continuous PU Sandwich Panel Machine

First, PU sandwich panel machine is to feed the rigid polyurethane virgin fluidto the mixing head through PU casting machine dosage pump by a certain ratioand uniformly cast onto the bottom steel panel which was formed by the lowerroll forming unit when well mixed. Second, PU sandwich panel machine is fed tothe laminating and pressing conveyor together with the top steel panel whichwas formed by the upper roll forming unit. Then they are solidified and shapedbetween the upper and lower chain planks. At last the solidified sandwich panelis cut into the required length by an automatic tracker cutter on theproduction line

Characteristics

1. Polyurethane High PressureFoam Machine

The concept of high pressure foam machine means that every customer can choosethe suitable equipment according to their requirement and budget. For example,measure system, temperature control system, mixing head and PLC controller canbe compound in the way of modularization, which gives the maximum flexibilityto the foam machine. Continuous PU sandwich panel machine also can be designedwith special control system according to customers' special requirements, whichcan meet the production needs and has the greatest flexibility. Continuous PUsandwich panel machine can meet the most complicated production requirementsand is suitable for a wide variety of applications. Especially it can matchwith the related equipment directly, forming a complete production line. Forexample, Continuous PU sandwich panel machine can match turntable mode frame,clamp, premixed devices, auto-coordinates, manipulator of apery type and so on.The pressure-proof chemical material can be used to store mixing materials witha low boiling point of vesicant or high-viscosity materials. All material cansare certified through the pressure vessel, with the visual level gauge in theoutside of the can. Paste is formed by the magnetic roller shaft and controlledby the floater machine, which can give the exact level of the materialsvisually.

2. The Production Technology of Thermal Insulation Panel

The production mode of PU Foam Sandwich Panel, as a structural or moisture application, can be continuous or non-continuous. Accordingto the request and budget of customer and the design of those two previousproduction lines, there are a wide variety of options, and each project ischaracterized in high productivity and best distribution of cellularpolyurethane. As our company has a number of related technologies, we can providea complete set of continuous PU sandwich panel machine, including the highlycompound production line of the foaming process, sheet metal forming, automaticconvey, producing programming and quality management. At the same time, we alsohave optional producing plans by using substitute-CFC vesicant, includingCarbon dioxide, which is widely accepted by industrial circle andenvironmentalists and has a low cost without any harm.

Links:https://www.globefindpro.com/products/106332.html

-

Hexagon Nut

Hexagon Nut

-

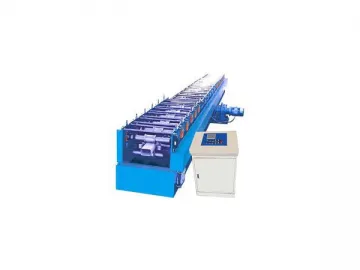

C Shape Purlin Machine

C Shape Purlin Machine

-

Deck Floor Roll Forming Machine

Deck Floor Roll Forming Machine

-

Louver Window Hinge

Louver Window Hinge

-

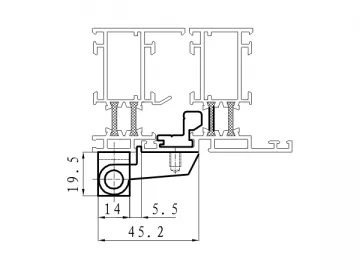

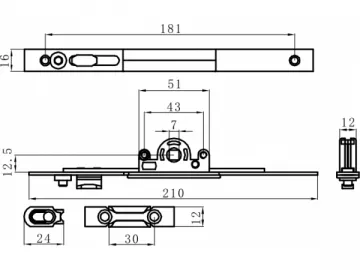

Casement Door Operator

Casement Door Operator

-

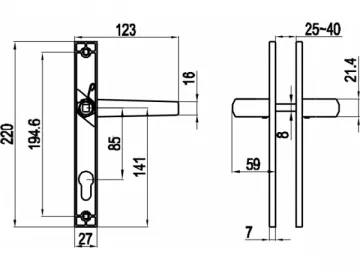

Folding Door Handle

Folding Door Handle

-

RF-2 Concealed Roof Panel Roll Forming Machine

RF-2 Concealed Roof Panel Roll Forming Machine

-

Auto Stacker

Auto Stacker

-

Downpipe Forming Machine

Downpipe Forming Machine

-

Z Shape Purlin Machine

Z Shape Purlin Machine

-

No-Girder Curve Roof Roll Forming Machine

No-Girder Curve Roof Roll Forming Machine

-

High-intensity Hexagon Nut

High-intensity Hexagon Nut