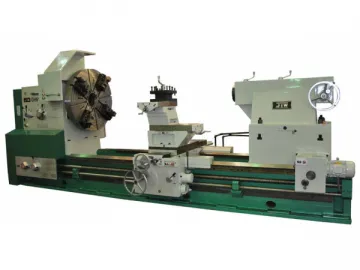

CNC Lathe SK6140H, SK6152H

CNC Lathe SK6140H, SK6152H

Features

1. The flat bed CNC latheSK6140H, SK6152H are controlled by computer and driven by servo motor.

2. It offers a modular structure and is connectable to PC through RS232C.

3. The spindle can work at an infinitely variable speed under the control of afrequency converter.

4. It has a 4-way automatic turret, high repeatability precision in location.

5. The CNC lathe can work out sophisticated work pieces such as tapers,spherical faces, threads and pieces in line or circular arc.

6. It uses the ISO standard code for programming, with cut-off protection anddiagnosis function, with input to be done manually on the keyboard.

7. Upon request, it can be equipped with Siemens CNC or Fanuc CNC system.

| Specifications | SK6140H | SK6152H | Standard Equipment |

| Max. swing over bed | 400mm | 520mm | 4 position turret |

| Max. swing over cross slide | 210mm | 335mm | GSK CNC System |

| Max. distance between centers | 750/1000/1500/2300mm | 250mm 3 jaw chuck | |

| Max. spindle thru-bore diameter | 80mm | ||

| Spindle taper bore | MT6 | ||

| Spindle speed | 150~2000RPM (infinitely variable) SK6140H 50~1600RPM (3 steps infinitely variable) SK6152H | ||

| Max. feed speed of X axis | 3000mm/min | ||

| Max. feed speed of Z axis | 6000mm/min | ||

| Feed rate of worktable of X axis | 3~2500mm/min | Optional Accessories | |

| Feed rate of worktable of Z axis | 6~3000mm/min | German FAG spindle bearing | |

| Tailstock quill diameter | 70mm | Hydraulic chuck and tailstock | |

| Tailstock quill travel | 150mm | Siemens 802D | |

| Taper type of tailstock quill | MT5 | 6 position turret | |

| Min. set unit of X axis | 0.001 or 0.005mm | Fanuc 0i-mate TC | |

| Min. set unit of Z axis | 0.001 or 0.01mm | ||

| No. of stations of the turret | 4 (standard) 6 (optional) | ||

| Position accuracy | X axis<0.016mm Z axis<0.025mm | ||

| Re-position accuracy | <0.01mm | ||

| Power of the main drive motor | 7.5kw | ||

As a China-based CNC lathe manufacturer since 1993, J&W has manufactured avast range of products that include vertical lathe, horizontal lathe, boringmilling machine, double column machining center, and more.

Links:https://www.globefindpro.com/products/106577.html

-

CNC Lathe SK6132H, SK6136H

CNC Lathe SK6132H, SK6136H

-

Horizontal Lathe GH62100Z, GH6280Z

Horizontal Lathe GH62100Z, GH6280Z

-

Vertical Lathe SLC400Q

Vertical Lathe SLC400Q

-

Raschel Bag TDRBH-001

Raschel Bag TDRBH-001

-

Horizontal Lathe GH6280Q

Horizontal Lathe GH6280Q

-

Raschel Bag on Rolls TRBR-006

Raschel Bag on Rolls TRBR-006

-

Bale Net Wrap PENW-002

Bale Net Wrap PENW-002

-

Knitted Bag TDRBT-013

Knitted Bag TDRBT-013

-

Raschel Bag TDRB-002

Raschel Bag TDRB-002

-

Vertical Lathe (S) LC630Q

Vertical Lathe (S) LC630Q

-

Horizontal Lathe GH61208Z

Horizontal Lathe GH61208Z

-

Pallet Netwrap PEPN-001

Pallet Netwrap PEPN-001