High Speed Paper Edge Protector Line ZJK120G

High Speed Paper Edge Protector Line ZJK120G

Features

1. Controlled by computer, the ZJK120G high speed paper edge protector line can produce V profile paper edge protectorat high speed, which can reach 50m/min.

2. The molding wheeluses box type suspended structure, so it is easy to change mold.

3. Using a touch screen and human-computer interface of servo system, theoperation of the high speed paper edge protector line is more personalizationand the operation for adjustment of air cylinder is more convenient.

4. It automatically counts the number of producing mission and output.

5. The glue pump can supply glue automatically in stable quantity, fastproducing speed and good quality at low temperature.

6. Using a hoist to load the raw materials, it can increase productionefficiency of the high speed paper edge protector line.

7. Using a double motor to adjust speed synchronously, itstraction force is more powerful.

8. Adoptingan automatic alarm and malfunction prompt function,the high speed paper edge protector line is easy to adjust and maintain.

Technical Specifications

| Model | ZJK120G |

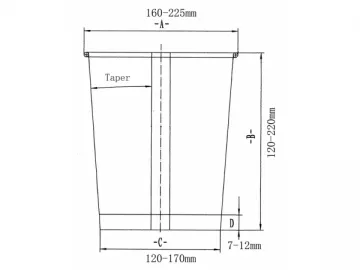

| V protector size (mm) | 25~120 (can be symmetrical and asymmetrical) |

| Thickness (mm) | Normally 3-6mm, special order for Max. thickness of 8mm. |

| Applicable inner paper | 420-600g/m2 fluting paper or corrugating medium paper |

| Applicable surface paper | 175-250gsm craft paper |

| Core diameter of paper roll | 3"(76mm) (4"or other size must be confirmed when making order) |

| Max. quantity of layer | 13 |

| Max. speed | 50m/min for length not smaller than 800mm. |

| Control system | PLC, servo motor, Touch screen (HIM) with automatic alarm and failure notice, easy for operation and adjustment. With output counting. |

| Paper stands | Composite stands with hoist for inner paper. Separate paper stand for surface paper. |

| Method to load paper roll | Load inner paper rolls by hoist (along with machine). Load surface paper roll by hydraulic manual car (bought by the buyer) which is also required to move jumbo paper roll. No need to stop machine when loading paper rolls. |

| Applicable paper roll diameter | Max.1300mm |

| Paper feeding and compounding | Step type with complex structure |

| Gluing system | Cascade type gluing system |

| Glue heating | Electrical heating with temperature control system |

| Glue feeding | Automatic feeding by diaphragm pump |

| Pressing adjustment | Pneumatic pressing to protect paper and easier operation |

| Protector heating | Electrical heating |

| Cut method | Hydraulic cutting |

| Quantity of cutter | 1 |

| Moving of cutting head | Servo motor controlled by PLC |

| Min cut length | 80cm |

| Cut tolerance | ±1mm |

| Stacker | Automatic stacking |

| Motor for forming section | Two motors with inverter, with high power |

| Power supply | Motor power:17KW Protector heating power: 6.5KW (normally for winter) Glue heating power: 4.5KW (normally for winter) |

| Air supply | 0.6Mpa,0.1m3 |

| Total weight(MT) | 6.5 |

| Dimension(m) | 24.5×2.3×4 |

| Operator | 2-3 workers |

| Required container | One 40"container |

Thank you for browsing our website! As aprofessional paper edge protector machinery manufacturer based in China, we atAMC can provide a comprehensive range of paper edge protector machinery,such as V profile paper edge protector machine, flat paper protector machine,roll cutting machine and more. Ourproducts, such as paper cup machinery, paper edge protector machinery, cartonmachinery, etc. are well received by global customers. If you are in need of any of our products, pleasecontact us directly. We are ready tohelp you.

Links:https://www.globefindpro.com/products/106987.html

-

Paper Plate Forming Machine DB300

Paper Plate Forming Machine DB300

-

ZJK120DPU/ZJK150DPU Paper Edge Protector Line

ZJK120DPU/ZJK150DPU Paper Edge Protector Line

-

Ice Cream Paper Cone Machine DB-B5

Ice Cream Paper Cone Machine DB-B5

-

Slitter Rewinder Machine FQ1600C

Slitter Rewinder Machine FQ1600C

-

Paper Edge Protector Line ZJK120D

Paper Edge Protector Line ZJK120D

-

Water Paper Cone Machine DB-B5W

Water Paper Cone Machine DB-B5W

-

High Speed Paper Cup Machine DBZB75

High Speed Paper Cup Machine DBZB75

-

Automatic Sheet Separator

Automatic Sheet Separator

-

Slitter Rewinder Machine FQ2500C

Slitter Rewinder Machine FQ2500C

-

Paper Dinner Case Forming Machine ZHCJ-II

Paper Dinner Case Forming Machine ZHCJ-II

-

ZJK120DP Paper Edge Protector Line

ZJK120DP Paper Edge Protector Line

-

High Speed Paper Bowl Machine DBZS-3

High Speed Paper Bowl Machine DBZS-3