ZJK120DPU/ZJK150DPU Paper Edge Protector Line

ZJK120DPU/ZJK150DPU Paper Edge Protector Line

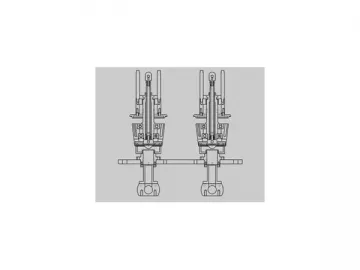

Our ZJK120DPU/ZJK150DPU paper edge protector line can produce V profile or U profile paper edge protectors or flat board paper edge protectors through changing the position of the forming wheelsand cutter. There is no need to changetools.

Features

1. Our paperedge protector line is the latest edge protector production line. It uses PLC control, composite stands,pneumatic pressure adjustment and servo motor.

2. Conversion ofproduction mode is carried out through lifting or lowering the forming wheelgroup pneumatically and changing the cutter position.

3. Featuring high speed,high precision and good quality, our paper edge protector line is the mostideal product in the field.

Technical Specifications

| Model | ZJK-120DPU | ZJK-150DPU |

| Max. V protector size(mm) | 120 | 120 |

| Min. V protector size(mm) | 25 | 25 |

| Flat protector width(mm) | 50 - 180 | 50 - 180 |

| U protector(mm) | (Width) 20 – 150 × (Height) Max. 45 mm | (Width) 15 – 150 × (Height) Max. 100 mm |

| Thickness of V protector(mm) | Normally 3-6mm, special order for max thickness of 8mm | Normally 3-6mm, special order for max thickness of 8mm |

| Thickness of flat board(mm) | 2.5-8mm | 2.5-8mm |

| Thickness of U protector(mm) | 2.5-4mm | 2.5-4mm |

| Applicable inner paper | 420-600g/m2 fluting paper or corrugating medium paper | 420-600g/m2 fluting paper or corrugating medium paper |

| Applicable surface paper | 175-250gsm craft paper | 175-250gsm craft paper |

| Core diameter of paper roll | 3"(76mm) (4"or other size must be confirmed when making order) | 3"(76mm) (4"or other size must be confirmed when making order) |

| Max. Layers for V protector | 13 layers | 13 layers |

| Max. Layers for flat board | 4 layers | 4 layers |

| Max. Layers for U protector | 6 layers | 6 layers |

| Max. speed | 25m/min(normal working speed 15-20m/min) | 25m/min(normal working speed 15-20m/min) |

| Control system | PLC, servo motor and touch screen(HMI) | PLC, servo motor and touch screen(HMI) |

| Paper stands | Composite stands | Composite stands |

| Paper feeding and compounding | Step type with complex structure | Step type with complex structure |

| Gluing system | Cascade type gluing system | Cascade type gluing system |

| Glue feeding | Automatic feeding by diaphragm pump | Automatic feeding by diaphragm pump |

| Transmission system | Coaxial transmission | Coaxial transmission |

| Pressing wheels adjustment | Pneumatic pressing | Pneumatic pressing |

| Required air flow | 0.2m3/h,0.8Mpa | 0.2m3/h,0.8Mpa |

| Cut method | Hydraulic cutting | Hydraulic cutting |

| Quantity of cutter | 2 | 2 |

| Min cut length | 60cm | 100cm |

| Cut tolerance | ±1mm | ±1mm |

| Power supply | 12KW | 12.25KW |

| Total weight | 5.5MT | 5.8MT |

| Dimension | 24×1.4×1.925m | 24×1.4×1.925m |

| Operator | 2 - 3 | 2 - 3 |

As a primary carton machine manufacturer based in China, AMC can provide globalcustomers with superior quality paper cup machinery, paper edge protectormachinery, carton machinery and more. Inorder to satisfy customer demands, we also provide other paper edge protectormachinery, like flat paper protector machine, V profile paper edge protectormachine, roll cutting machine, etc. Ifyou have a need for any of our products, please feel free to contact us viaemail or contact address available on this website.

Links:https://www.globefindpro.com/products/106989.html

-

Ice Cream Paper Cone Machine DB-B5

Ice Cream Paper Cone Machine DB-B5

-

Slitter Rewinder Machine FQ1600C

Slitter Rewinder Machine FQ1600C

-

Paper Edge Protector Line ZJK120D

Paper Edge Protector Line ZJK120D

-

Water Paper Cone Machine DB-B5W

Water Paper Cone Machine DB-B5W

-

Paper Cutting Machine

Paper Cutting Machine

-

PBK800 Flat Board Edge Protector Production Line

PBK800 Flat Board Edge Protector Production Line

-

Paper Plate Forming Machine DB300

Paper Plate Forming Machine DB300

-

High Speed Paper Edge Protector Line ZJK120G

High Speed Paper Edge Protector Line ZJK120G

-

High Speed Paper Cup Machine DBZB75

High Speed Paper Cup Machine DBZB75

-

Automatic Sheet Separator

Automatic Sheet Separator

-

Slitter Rewinder Machine FQ2500C

Slitter Rewinder Machine FQ2500C

-

Paper Dinner Case Forming Machine ZHCJ-II

Paper Dinner Case Forming Machine ZHCJ-II