Paper Cutting Machine

Paper Cutting Machine

Along with the use of honeycomb paper, we know that honeycomb paper board is a pro-environment product. It is a new type of material that features low cost and will be extensively developed for future uses. Many factories can manufacture the honeycomb paper board equipment, but few can match our high speed and high quality. The reason is in the link of paper core cutting. Using digital display and computer control, our 1860 type cutting machine can help you deal with the problem. It can cut different honeycomb paper board. We can design and produce different paper cutting machines, according to the requirements of our customers.

Structure Features

1. Pair worm wheel pull knife system

Using a pair worm wheel pull knife system to improve the single pull knife structure ensures the honeycomb paper core will have more precision.

2. Strengthen straight line lead rail

Because of the 1860 type cutting machine, the paper-pusher is larger, so we use the strengthen straight line lead rail to make paper-pusher flexible and ensure material precision. (If we use the common gag level lead rail, the work load and accuracy error is larger). At the same time it can be unbearable to strike. Because the paper core block is heavy, the inertia force is larger and the feeding position has more impact force for the paper-pusher.

3. Safety protective device

In order to make the operating staff safer and the machine more reliable, we have designed many safety devices.

a. An infrared ray protector device is used to avoid the operating staff in case of action miss and make personal harm.

b. There is a knife bed electronic knife lock.

If the mechanical or electrical appliances have some abnormal conditions, the electronic knife lock will lock the knife bed by itself and the cutting machine will stop to wait for a back-check.

c. Pull rod safety protective device

We have installed the highest sensitivity safety switch on the right and left pull rod. If the cutting machine suffers a excess load and the safety bolts become less crowded or makes the pull rod safety bolt break, the highest sensitivity safety switch activate, the electromagnetic clutch will lose electricity, and the knife bed will stop glissade to avoid harming the machine.

4. Air cushion system and chrome plate panel

Using an air cushion system and chrome plate panel to cut the massive honeycomb paper core will be easy. The paper cutting machine can be equipped various kinds of air pumps, in order to perform at optimum work conditions.

Technical Specifications

Item | Unit | QZK1860 |

Max. cutting width | mm | 1860 (73.2") |

Max. cutting length | mm | 1950 (76.8") |

Max. cutting height | mm | 165 (6.5") |

Max. clamp pressure | N | 65000 |

Main motor | kw | 7.5 |

Weight | kg | 9000 |

Cutting speed | time/min | 40 |

As a China-based manufacturer and suppler of paper edge protector machine, AMC also provides flat paper protector machine, V profile paper edge protector machine, roll cutting machine and U profile paper edge protector, etc. If you have any need for our paper cup machinery, paper edge protector machinery or carton machinery, please feel free to contact us.

Links:https://www.globefindpro.com/products/106994.html

-

PBK800 Flat Board Edge Protector Production Line

PBK800 Flat Board Edge Protector Production Line

-

ZJK120DU Paper Edge Protector Line

ZJK120DU Paper Edge Protector Line

-

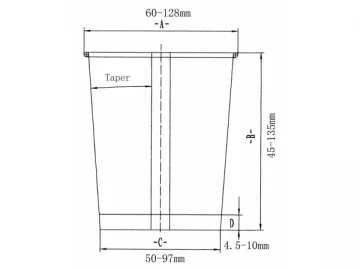

Paper Cup Machine DB-C

Paper Cup Machine DB-C

-

Plastic Cup Lid Forming Machine DB340

Plastic Cup Lid Forming Machine DB340

-

Paper Protector Punch Cutting Machine

Paper Protector Punch Cutting Machine

-

Automatic Flute Laminator

Automatic Flute Laminator

-

Water Paper Cone Machine DB-B5W

Water Paper Cone Machine DB-B5W

-

Paper Edge Protector Line ZJK120D

Paper Edge Protector Line ZJK120D

-

Slitter Rewinder Machine FQ1600C

Slitter Rewinder Machine FQ1600C

-

Ice Cream Paper Cone Machine DB-B5

Ice Cream Paper Cone Machine DB-B5

-

ZJK120DPU/ZJK150DPU Paper Edge Protector Line

ZJK120DPU/ZJK150DPU Paper Edge Protector Line

-

Paper Plate Forming Machine DB300

Paper Plate Forming Machine DB300