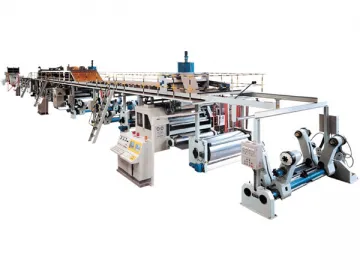

5-Ply Corrugated Board Production Line

5-Ply Corrugated Board Production Line

Features

1.As special equipment used to produce corrugated board, the WJ100-1800 5-ply corrugated board production line includes mill roll stand, single facer, conveyor bridge, glue machine, double facer, pre-heaters, preconditions, slitter scorer, cut-off stacker, steam hearting system, glue preparing and supplying system.

2. Our 5-ply corrugated board production line can finish such processes as paper-feeding, medium-fluting, glue applying, forming, drying, scoring, cutting as well as stacking and conveying.

3. We can offer advanced, medium and common 5-ply corrugated board production lines for single wall, double wall and triple wall corrugated board production with speed ranging from 100m/min to 250m/min and width ranging from 1400mm to 2500mm.

Technical Specifications

1. Design speed: 100m/min

2. Economic speed: 80m/min

3. Working width: 1800mm

4. Total length of corrugated board production line is about 68 meter (following foundation drawings)

5. Flute profiles: A, B, or according to client’s requirements

6. Steam requirements:

Steam quantity: 2500--3200Kg/Hr

Max. pressure: 1.6Mpa

Normal pressure: 0.98--1.12MPa

7. Electricity: 380V 50Hz three-phase or four phase

8. Total machinery power: About 282kw.

Normal machinery power: About 230kw

9. Shop area that machinery requires: About 80m x 10m x 4.5m (length x width x height)

10. Equipment direction: Left or right transmission will be according to client’s requirements.

Note: Customer Provided Parts

1. Steam heating system: one set of boiler of 4000Kg/Hr, pressure 1.4-1.6MPa

2. Steam pipelines above valves and steam back, water pipelines

3. Compressed air pipelines, glue pipelines

4. Power, electric wire to operation box

5. Water pipelines, water barrel

6. Water, electricity, steam ground foundation

7. Raw materials (paper roll, corn starch, caustic soda, sodium borax) to test machinery

8. Engine oil, lubricating oil, hydraulic oil, LUB and high-resisting LUB

9. Installation and commissioning persons food and boarding, and person arrangement

5-Layer Corrugated Board Production Line Equipment List

Name | Quantity | Remark | |

1 | Mill roll stand | 5 | Hydraulic lift-lower, clamp and move |

2 | Railing for reels | 10 | |

3 | Single facer | 2 | Corrugated roller ¢280mm, electric motion to adjust the gluing width, corrugated roller made in Beijing |

4 | Pre-heater | 2 | ¢600mm electric motion adjust wrapping angle |

5 | Pre-adjustor | 2 | ¢600mm electric motion adjust wrapping angle |

6 | Double layer feeding bridge | 1 | Adopt adsorption style motorized correct deflection |

7 | Triple pre-heater | 1 | ¢600mmelectric motion adjust wrapping angle |

8 | Gluing machine | 1 | Pneumatically adjust pressure roller |

9 | Double facer | 1 | 520mm×15 heating plates, matching with cooling section |

10 | Thin blade slitter scorer | 1 | 5 blades 8 score, left-right movement |

11 | NC Cutoff | 1 | Rotary blasé made in Taiwan, main bearing made in NSK, Japan |

12 | Main transmission | 1 | Diameter 636mm type |

13 | Carton transport machine | 1 | With horizontal part |

14 | Glue making system | 1 | Circulation glue, Pipelines provided by consumer |

15 | Electric system | 1 | |

16 | Steam system | 1 | Pipelines above valve provided by consumer |

17 | Pneumatic system | 1 |

AMC is a professional corrugated board production machine manufacturer, based in China. Our main products are paper edge protector machinery, paper cup machinery, and carton machinery. In addition to corrugated board production machine, we also produce carton gluer, die cut machine, carton slotter, and more. If you have any related need, please feel free to contact us. We are ready to serve you.

Links:https://www.globefindpro.com/products/107036.html

-

GMVP Automatic Flexo Printer Slotter, Die Cutter

GMVP Automatic Flexo Printer Slotter, Die Cutter

-

Flexo Printer Slotter, Die Cutter Folder Gluer Counter Ejector FFG

Flexo Printer Slotter, Die Cutter Folder Gluer Counter Ejector FFG

-

Carton Die Cutting Creasing Machine (Automatic Platen)

Carton Die Cutting Creasing Machine (Automatic Platen)

-

Harvester Diesel Engine, L Series(Power From 32.4kw To 56kw)

Harvester Diesel Engine, L Series(Power From 32.4kw To 56kw)

-

Hexagonal Wire Mesh

Hexagonal Wire Mesh

-

Harvester Diesel Engine, QC(Power From 66kw To 81kw)

Harvester Diesel Engine, QC(Power From 66kw To 81kw)

-

Semi-automatic High Speed Stitching Machine

Semi-automatic High Speed Stitching Machine

-

Mesh Disc, Slit Mesh

Mesh Disc, Slit Mesh

-

Epoxy Coated Wire Mesh

Epoxy Coated Wire Mesh

-

SG-2460 Semi Automatic Gluer

SG-2460 Semi Automatic Gluer

-

Stitching Machine

Stitching Machine

-

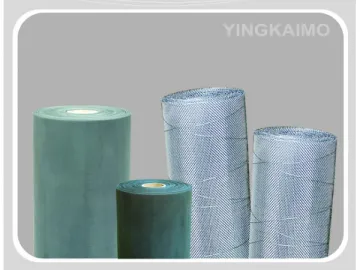

Knitted Wire Mesh

Knitted Wire Mesh