CL Series Leather Cutting System

CL Series Leather Cutting System

Description

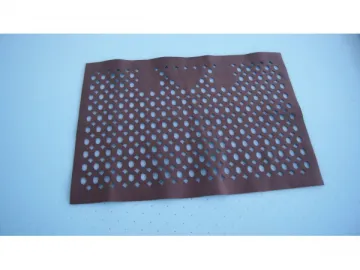

The CL system uses themost powerful automatic nesting software in the industry to maximize theutilization of leather. The CL system reduces production costs andmaximizes the utilization of the leather. By laying out apattern via projectors, the CL Series leather cutting can cut various types of irregular genuine leather, artificial leather, synthetic materials,etc. accurately at high speed, without sample patterns and cutting dies. It greatly saves on customer development timeand expenses. It is the optimal choicefor new product development and mass production. The CL Series leather cutting systemincreases the cutting speed and saves on labor costs while eliminating the needfor manual die cutting operations. TheCL Series leather cutting system offers quality and precision of the cuttingresults. Computerized automatic cuttingensures stable and reliable quality and precision, even for such details asnotches, etc. and guarantees a high standard of sewing quality.

Features

1. The CL Series leather cutting system’s headpiece adapts the design ofmodular compounding and can be used in punching, scribing and cutting. It also has the character of scalability.

2. The configurations of the CL Series leather cutting system’s plotter arelight locomotive and assembly line position. The function of circular supply helps save time.

3. The CL Series leather cutting system has an LCD touch screen panel thatuses a user-friendly interface, making it easy to learn and operate.

4. The CL Series leather cutting system has a pneumatic pen that canconnect with the pre-sample making platform and help facilitate the operation.

Application

CL series leather cutting systemis used in the leather industry.

Technical Specifications

| Model No. | CL-1510 | CL-2510 | CL-3020 |

| Features | PC controlled/Lasor Locating/Dual-projector, digital camera photography technology/simultaneous nesting & cutting tasks/excellent time saver | ||

| Cutting speed | Up to 100mm/s | ||

| Cutting Media | Kinds of leather, artificial leather, paper, cardboard, composite materials, etc. | ||

| Cutting Depth | leather, skin, artificial leather, PU ≤4mm / composite cardboards ≤15mm | ||

| Knife Tool | Osciallting Knife (1 set), Punching Knife (1.5mm/3mm per each set)/ Die cutting Knife (1 set) | ||

| Pen Tool | Silver Refill Pen, Ball Pen. Oil Pen, Gel-ink Pen | ||

| Media Fixture Device | Vacuum suction | ||

| Repeat Precision | ≤0.1mm | ||

| Projector Resolution | 1024*768 Pixels | ||

| Oscillating Frequency | 10000-18000 RPM | ||

| Programmable Resolution | 0.025 / 0.01 / 0.1 available | ||

| Interface | Ethernet port & Serial port | ||

| Buffer Memory | 1G | ||

| Data transfer rate | 100MB/S | ||

| Command Mode | HP-GL compatible format | ||

| Control Panel | Touch screen | ||

| Transmission System | Digital servo driver; straight rail; synchronous belt | ||

| Power Supply | Motor: AC 220V±10% 50HZ/10A Vacuum Pump: AC 380V±10% 50HZ/25A | ||

| Fuse | 6A、30A | ||

| Working Environment | 10 to 35 deg.C | ||

| Cutting Area | 1500mm*1000 mm | 2500mm*1000 mm | 3000mm*2000 mm |

JINGWEI is China-based leather cutting system manufacturer and supplier. We offer leather cutting systems, POP displaycutting tables and lampshade plotters. Ourhigh quality products are offered at competitive prices. Our company can supply the full chain ofmanufacturing architectural model makers and shoe sample making machinesright here in China. Our lower manufacturing cost saves yourpurchasing cost. More details of eachproduct are shown on the description page.

Links:https://www.globefindpro.com/products/107303.html

-

POP/POS Display

POP/POS Display

-

Telephone Bluetooth Handsfree

Telephone Bluetooth Handsfree

-

Recordable Headband Bluetooth Headset

Recordable Headband Bluetooth Headset

-

Carbon Steel Tube for General Structural

Carbon Steel Tube for General Structural

-

EDO-3A Series Cutting Plotter

EDO-3A Series Cutting Plotter

-

Seamless Carbon and Alloy Steel Structural Pipe

Seamless Carbon and Alloy Steel Structural Pipe

-

Multipoint Mono Bluetooth Headset

Multipoint Mono Bluetooth Headset

-

Hi-Fi Stereo Bluetooth Headset

Hi-Fi Stereo Bluetooth Headset

-

Computer Bluetooth Kits

Computer Bluetooth Kits

-

Electronics

Electronics

-

On Board Flake Ice Machine

On Board Flake Ice Machine

-

Tube Ice Making Machine

Tube Ice Making Machine