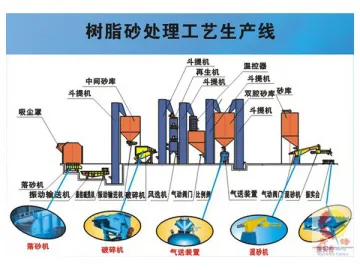

Resin Sand Processing Equipment

ResinSand Processing Equipment

The resin sand processingequipment layout shall be appropriately formulated according to the castingplant layout, technologic property and production requirements. Its processflow is composed of used sand recovery, used sand crushing and regeneration, used sand magneticseparation and screening, used sand air separation andthermoregulation, new sand system, (new) used sandstorage, sand mixing, sand molding, core sand making,etc.

1. Used Sand Recovery

The used sand and scattered sand are conveyed to the sand silo by the conveyor after theirseparation with castings and sand box through the shakeout. The magneticsubstance will be separated by the suspension magnetic separator, belt-typepermanent-magnet separator and other magnetic separation equipment.

2. Used Sand Crushing and Regeneration

The sand lump in the sandlump silo is fed into the crusher evenly and quantificationally through thevibrating feeder, and will be regenerated successively through the roastingfurnace and regenerator after crushing and screening, and finally be conveyedinto the heat sand silo by the conveyor. The magnetic substance will beseparated from the used sand through the magnetic separation equipment. The usedsand will have the preliminary cooling and dedusting through the induction fanand dedusting pipeline.

3. Used Sand Air Separation and Thermoregulation

The hot used sand containingmicro powder is evenly fed by the curtain type distributing device. The micropower is drawn out by air separator. The sand will flow into the sandtemperature regulator and have the heat exchange operation. Finally, thequalified used sand that can reach the required temperature will be conveyedinto the used sand silo by the conveyor.

4. New Sand System

The new green sand will beconveyed into the new sand silo by the conveyor after being dried by the newsand drying system with three return strokes.

5. Sand Mixing, Sand Molding,Core Sand Making

After being matched in a certain ratio, the new and used sand will be mixedaccording to the technical requirements to produce the qualified molding sandthrough the self-hardening sand mixing machine. The qualified sand will then befed into the sand box or core box. After hardening, molding, mold modification,coating and surface drying, the qualified sand will be conveyed to the pouringprocess. After the castings are cooled to the required temperature, thecastings will have the shakeout operation, and the used sand will be recovered.

Doublestar is a China-based resin sand processing equipment manufacturer,established in 1970, and has been ISO9001:2000 and SO14001:2004 certified. Weprovide rolling shot blast machine, steel pretreatment equipment, green sandpreparation equipment, car type blast cleaning equipment, pass-through blastcleaning equipment, and hook shot blast machine. Our products are reliable inquality and reasonable in price. Our sand preparation equipment has beenexported to Russia, Thailand, Vietnam,Germany, India, Singapore and other countries. Ourcompany is located in Jiaonan City, Shandong Province where we haveconvenient access to any kind of transportation, which not only can save ourtransportation cost of raw materials, but can lower your purchasing cost. Ifyou would like more information about our products, we welcome you to contactus at any time!

Links:https://www.globefindpro.com/products/107956.html

-

Q69 Blast Cleaning Equipment

Q69 Blast Cleaning Equipment

-

LED Signal Warning Device System

LED Signal Warning Device System

-

Green Sand Preparation Equipment

Green Sand Preparation Equipment

-

Q36 Blast Cleaning Equipment

Q36 Blast Cleaning Equipment

-

1.2m T8 LED Tube

1.2m T8 LED Tube

-

LED Cap Lamp

LED Cap Lamp

-

Wireless LED Cap Lamp KL2L7M

Wireless LED Cap Lamp KL2L7M

-

Q76 Blast Cleaning Equipment

Q76 Blast Cleaning Equipment

-

Q69 Stainless Steel Blast Cleaning Equipment

Q69 Stainless Steel Blast Cleaning Equipment

-

QH69 Blast Cleaning Equipment

QH69 Blast Cleaning Equipment

-

T8 LED Tube with Remote Control

T8 LED Tube with Remote Control

-

T8 LED Tube with Light Fixture

T8 LED Tube with Light Fixture