PB and OSB Production Line

PB andOSB Production Line

As its name suggests, PB and OSBproduction line is designed to manufacture particle boards and oriental shaving boards. We at Jechencan manufacture continuous flat pressing type and continuous roller pressingtype PB production lines, and multilayer and single layer particle board hotpress. Please refer to corresponding pages for detailed information.

Configuration and production processes

Jechen PB production line or OSBproduction line is composed of material-preparation, drying,adhesive-mixing, preforming and hot pressing, coolingand edge-cutting, and sanding and polishing sections.

Given below are the production procedures.

1. The material preparation section consists of the chipping machine andsanding machine. The chipper functions to chip wood material into sheets whichare then processed into shavings by the sander.

2. Next, the shavings are delivered to drying equipment for drying.

3. Dried shavings are then transferred to adhesive-mixing section which isprimarily composed of glue mixer. The mixer coats the shavings with binderevenly.

4. Then, the shavings are sent to preforming and hotpressing section which includes pre-forming machine, pre-pressing machine,conveying equipment and hot press. Shaving board, also called particle board,is roughly achieved at this step, through steps like preforming,prepressing, and hot pressing.

5. Cooling equipment and edge cutting machine constitutes the cooling andedge-cutting section. The hot pressed particle board is firstly cooled and thentrimmed to offer smooth edges.

6. Finally, the particleboards are polished by the sanding equipment at thefinal section of PB production line or OSB production line.

Applications

1. PB production line is designedto produce particle board which is typically manufactured from materials likewood chips, sawmill shavings, and other wood particles. Chipboard isextensively used in industries like furniture, architectural decoration, interiordecoration of vehicle and ship, etc.

2. OSB production line isdifferent from conventional chipboard production lines in following threeaspects: OSB production line has high requirement for raw materials which mustbe small diameter lumber; its material preparation section is mainly composedof long lumber shaving machine instead of chipping machine; and the pre-formingmachine comes with orienting device. Oriental shaving board is commonly used for manufacturing packagingmaterial, flooring, furniture, and more, and it also ideal for composing woodenstructures.

Detailed production process

With a complete PB production line or OSB production line, users canproduce particle boards or oriental shaving boards according to followingproduction procedures.

1. Material preparation

Raw materials are chipped first, and qualified wood chips are delivered tostorage bin for temporary storage. Then,the wood chips are transferred to flaking machine for further processing, andwet wood shavings are produced storagebin.

2. Material drying, sorting, and sanding

The wet shavings are sent to rotor dryingequipment for drying. Then sort out the qualified, dried ones and send them tocorresponding storage bin. Oversized shavings are sanded before sending totheir corresponding storage bin.

3. Adhesive-mixing

The PB production line or OSB production line also includes wood shavingconveyor and weighting system which functions to convey and weight thequalified wood shavings delivered from previous procedure. Then, the shavingsare sent to the mixer, and in the meanwhile, binder feeding device feeds thebinder the mixer as well. Thus, the shavings are coated with the binderuniformly in the mixer.

4. Pre-forming and hot pressing

Through belt conveyor, the binder coated shavings areconveyed to mechanical pre-forming machine which finally offers flatsemi-finished particle boards. Undergoing permanent magnetic iron removal,pre-pressing, edge cutting, cross cutting, accelerating conveyor conveying and weighting,the semi finished products are finally sent to a loading cage. Afterwards, theloading cage delivers the semi finished particle boards to multilayer hot press.Hot pressed boards are ultimately pulled into an unloader.

5. Post-processing

The particleboards in the unloaderare delivered to cooling equipment via two steps conveying. Next, the cooled partialboards are conveyed to edge-cutting section for edge trimming and crosscutting. Then, they are transferred to hydraulic stacker which will unloadmaterials to forklift trucks when the stack height reachesto a proper height. Finally, they are transported to semi finished productwarehousing via the forklift trucks. They are required to be placed there for acertain period of time, thus balancing the water content of particleboards and makingproduct temperature approaching to ambient temperature.

6. Sanding

Following post processing step, the particle boards aretransported to sanding section of PB production line or OSB production line. Welltrimmed particleboards are then sanded to remove superficial precuring layer, according to related board thicknessrequirement. After this, partial boards coming with uniform thickness and smoothsurface are achieved, and their specification tolerance conforms to relatedstandard.

Electrical control system

Equipped with PLC control system, Jechen partial boardproduction line is able to achieve data collection, analysis, calculation andoutput, etc., thus allowing each section to operate continuously and smoothly. Theoperation status of the entire PB production line or OSB production line can bedisplayed clearly via a flow chart.

Jechen is amajor manufacturer of PBand OSBproduction line, based in China.We offer various types of products such as PB and OSB production line, single boardmachine, MDFand HDFproduction line (fiberboard) and so on. Our products are high quality andcompetitively priced. Our full chain of manufacturing refiner, multi-layer MDF and HDF hotpress can be completed in China,even in one city. Our lower manufacturing cost can save your purchasing cost. Amore detailed description of our product is shown on the page.

Links:https://www.globefindpro.com/products/108834.html

-

MDF Steaming Production Line

MDF Steaming Production Line

-

Luxury Yacht Mold

Luxury Yacht Mold

-

Luxury Composites Yacht Hull

Luxury Composites Yacht Hull

-

Continuous Roller MDF/HDF Production Line

Continuous Roller MDF/HDF Production Line

-

Wind Turbine Nacelle Cover Mold

Wind Turbine Nacelle Cover Mold

-

Multi-layer MDF/HDF Hot Press

Multi-layer MDF/HDF Hot Press

-

Agricultural Safety Cover

Agricultural Safety Cover

-

Freezing Goods Transportation Solution

Freezing Goods Transportation Solution

-

Rs232 Output Fuel Sensor

Rs232 Output Fuel Sensor

-

Vehicle GPS Tracker GP4000

Vehicle GPS Tracker GP4000

-

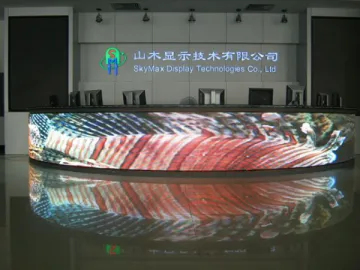

P8 SMD Indoor Virtual LED Display

P8 SMD Indoor Virtual LED Display

-

P7.62 SMD 3-in-1 Indoor LED Display

P7.62 SMD 3-in-1 Indoor LED Display