MDF and HDF Production Line (Fiberboard)

MDF andHDF Production Line (Fiberboard)

Why choose JECHEN?

1. Reliable equipment performance

JECHEN MDF production line and HDF production line are equipped withsuperior quality components under brandname of Siemens, REXROTH, SKF, ABB, and more. This ensures precision andstable performances.

2. Great popularity

Over 160 categories of HDF production line and a number of types of particleboard production lines are available here. According to total sales quantityand annual sales quantity, they have ranked top 2 in Chinese market for continuous 10 years and, additionally,our medium density and high density fiberboard production lines are soughtafter by clients from Brazil,Azerbaijan, Indonesia, Pakistan,Vietnam, Brazil, Yemen,India,etc.

3. Continuous innovation

While maintaining quality, we at Jechen also makeconstant efforts to improve production technologies, so as to offer up-to-dateMDF and HDF production line to worldwide customers. We have a design teamcomposed of over 50 designers, and meanwhile, we also cooperate withenterprises like Germany’s BINOS, PALLMANN, Italy’sIMAL,and PAL, etc. to achieve technical improvements.

4. Thoughtful customer service

Jechen has its independent MDF experimental plant,professional MDF production line and HDF production line designers, anddedicated custom service team. It can provide customers with custom design,user training, installation guidance, testing and commissioning, equipmentmaintenance and many other technical supports and services. Hence, clients canfeel totally secure in placing orders from us. More detailed service items aregiven at SERVICE page.

Applications

MDF production line isdesign for manufacturing medium density fiberboard which is commonly used infurniture making and decoration industries, and HDF production line is idealfor manufacturing high density fiberboard which is the base material forlaminated floor production.

Configuration and production processes

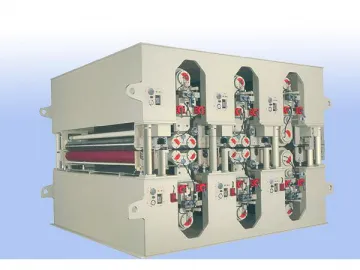

An entire MDF production line or HDF production line is composed of sectionsfor material-preparation, hot-grinding, drying, pre-forming and hot-pressing,cooling and edge-cutting, and sanding and polishing, etc.

Given below are the production processes:

1. The key component of material-preparation section is chipping machine whichfunctions to chip wood material into sheets.

2. Next, the sheets are transferred to hot-grinding section which mainlyincludes hot grinding equipment. Wooden sheets are cooked and steamed here, andthen break down into fiber which is then mixed with adhesive.

3. Then, the fiber-adhesive mixture is dried by the drying equipment. Driedmaterials will be delivered to next procedure via wind pipes.

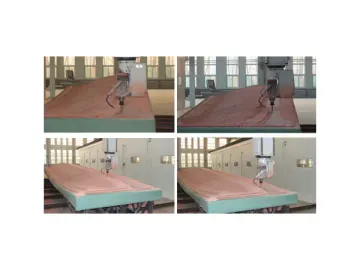

4. Pre-forming and hot-pressing section is primarily composed of pre formingmachine, pre pressing machine, conveying machine, and hot pressing machine.High density fiberboard or medium density board is roughly produced at thisstep, through steps like pre-forming, pre-pressing and hot pressing, etc.

5. Cooling and edge-cutting section is composed of cooling equipment and edgecutting machinery. The hot-pressed fiberboard is firstly cooled and thentrimmed to offer smooth edges.

6. Finally, the fiberboards are polished by the sanding machine at the lastsection of the MDF and HDF production line. Thus, well-processed fiberboardsare achieved.

Jechen is amajor manufacturer of MDF andHDF production line, based in China. We offer various types ofproducts such as fiberboardproduction line, PB production line, single board machine and so on. Ourproducts are high quality and competitively priced. Our full chain ofmanufacturing multilayer hot press, MDF steaming production line can becompleted in China,even in one city. Our lower manufacturing cost can save your purchasing cost. Amore detailed description of our product is shown on the page.

Links:https://www.globefindpro.com/products/108854.html