Paper and Plastic Coating Laminating Machine

Paper and Plastic Coating Laminating Machine

JZLM90-1500

Features

1. The paper and plastic coatinglaminating machine makes use of advanced electric and mechanical mechanism forimplementation of the whole process from substrate unwinding, laminating moulding, and rewinding. The highly automatic coatinglaminating machine comes with sophisticated PLC controller and human-machineinterface, providing independent and group control linkage.

2. The paper and plastic coating laminating machine provides double-stationunwinding, and pneumatic rectifier for automatic guiding and rectifying. Rollchanging is conducted at high speed without reducing working speed, and the unwindingtension uses PLC controller to ensure smooth and high speed unwinding.

3. Thespeed of extrusion and molding is controlled by PLC. The molding roller,silicone roller and assistant cooling roller comewith circulated water cooling structure, which guaranteesexcellent coating effect. The molding rollers are controlled pneumatically.

4. The paper and plastic coating laminating machine offers vector inverter and PLC control of the double-working-position rewinding. Automatic coil changing and cutting are performed without reducing workingspeed.

The paper andplastic coating laminating machine is applicable to PP, PE, BOPP, woven cloth, non-wovenfabrics, paper, aluminum foil, and other materials. As a kind of the mostadvanced hot melt coating laminating equipment in China, this machine is made usingpatented technology and makes quality products that feature strong adhesion,uniform thickness, and excellent leak tightness.

Main TechnicalParameters

1. Screw diameter: φ90mm, L/D: 32:1, Material: 38CrMoAl, tempered and surface nitrided.

2. T shaped elastic mould: new type feather edge mould.

3. High strength hard tooth surface gearbox withgreat airtightness and high reliability is utilized, providinglarge capacity, low noise, long use life, and steadytransmission.

4. Applicable materials: roll base paper, PET, BOPP, and other materials.

5. Coating materials: PE, PP

6. Coating width: 1100-1500mm

7. Coating thickness: 0.012-0.035mm (single layer)

8. Evenness of coating: error ±6%

9. Stripping strength: 3-5N/30mm (according to the coating basic material)

10. Max. extrusion capacity: 180kg/h

11. Machine speed: 0-150m/min

12. The paper and plastic coating laminating machine offers double-shaftdouble-station roll unwinding, roll changing without reducing working speed,automatic cutting, as well as automatic tension control by a vector-controlledconverter motor. Trolley type automatic pneumaticrectifying system isused, providing rectifying journey of ±100mm, and deviation rectifying precision of ±0.5mm.

13. The coating laminating machine comes with double-shaft, double-stationcenter rewinding, roll changing at high speed without deceleration, andautomatic cutting. In addition, themachine provides auto vector inverter control of rewinding tension (Imported PLC module control for taper tension).

14. Max. diameter for unwinding and rewinding: 1,200mm

15. Pneumatic roller for unwinding and rewinding: 3”(diameter: φ76mm)

16. Total power: about 130 Kw

17. Size (L×W×H): 8,500mm×8,500mm×3,200mm

18. Total weight: about 18,000kg

JIANGNAN LIGHT INDUSTRY MACHINERY COMPANY is a majormanufacturer of paper and plastic coating laminating machine, based in China. We offervarious types of products such as paper and plastic coatinglaminating machine, hydraulic pressure punching machine, asepsis liquid fillingmachine and so on. Our products are high quality and competitively priced. Ourfull chain of manufacturing high speed plastic coating laminating machine,blowing and printing machine can be completed in China, even in one city. Ourlower manufacturing cost can save your purchasing cost. A more detaileddescription of our product is shown on the page.

Links:https://www.globefindpro.com/products/109044.html

-

JSY-350 Film Blowing and Printing Machine

JSY-350 Film Blowing and Printing Machine

-

SL-45-600 Film Blowing Machine (Rotary Die)

SL-45-600 Film Blowing Machine (Rotary Die)

-

Non-Woven Coating Laminating Machine

Non-Woven Coating Laminating Machine

-

Dry Type Laminating Machine

Dry Type Laminating Machine

-

Travel Product Packaging Paper Coating Laminating Machine

Travel Product Packaging Paper Coating Laminating Machine

-

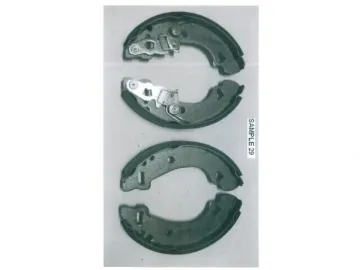

Brake Shoe

Brake Shoe

-

High Speed Paper and Plastic Coating Laminating Machine

High Speed Paper and Plastic Coating Laminating Machine

-

Printing and Coating Laminating Machine

Printing and Coating Laminating Machine

-

SL-65-1000 High Speed Film Blowing Machine

SL-65-1000 High Speed Film Blowing Machine

-

Multilayer Coating Laminating Machine

Multilayer Coating Laminating Machine

-

SL-45-600 Film Blowing Machine

SL-45-600 Film Blowing Machine

-

Paper Printing Machine (Shaftless Transmission High Speed Gravure Printer)

Paper Printing Machine (Shaftless Transmission High Speed Gravure Printer)