Dry Type Laminating Machine

Dry Type Laminating Machine

JF—1000

Application

The dry type laminating machine is typically used for dry laminating of such roll base materials as PET, nylon, CPP, CPE, aluminum foil, and paper, to name a few.

Technical Parameters

1. Coating width: 400-1000mm

2. Coating method: direct anilox roll coating

3. The dry type laminating machine uses electrical oven heating, with the hot air recycled for secondary use and energy conservation. It comes with independent piecewise constant temperature drying system, together with electronic temperature measuring device, providing auto temperature control. The air intake and discharge unit can be adjusted to offer strong air flow and thus thorough drying.

4. Electric oven opening type: Oven lid with air impulsion, making it convenient for material loading.

5. The dry type laminating machine has the guiding roller in the oven offer active control. Rollers are linked by synchronous belt for transmission, and also, vector inverter control system is utilized to keep at the same step with the main motor.

6. Max. mechanical speed: 0-150m/min, line speed in real production: 0-120m/min

7. First unwinding device: The dry type laminating machine uses independent single-station unwinding frame, vector frequency control of tension, and trolley-type automatic gas-sensitive rectifying device, with the rectifying length of ±100mm.

8. Second unwinding device: This unwinder makes use of independent single-station unwinding frame, magnetic powder brake for tension control, and automatic photoelectrical rectifying with the rectifying length of ±100mm.

9. The independent single-station rewinder provides automatic vector frequency control of taper tension.

10. Automatic length counting while rewinding.

11. The dry type laminating machine provides advanced PLC control system and human-machine control panel. The processes of unwinding, dip-coating, transmission in the oven, laminating, and rewinding are kept at the same pace. In addition to constant speed and steady tension control, the laminating machine enables operators to control unwinding and winding independently.

12. Max. diameter of first unwinding: 1,000mm, Max. diameter of second unwinding: 600mm, Max. diameter of rewinding: 1,000mm.

13. Pneumatic roller for unwinding and rewinding: 3 inch (φ76mm)

14. Power: 130kw

15.Overall size (L×W×H): 1300×2100×3500(mm)

16. Total weight: 12,000kg

This laminating machine is typically used for double or multiple laminating of wide roll materials such as BOPP, PET, nylon, CPP, CPE, aluminum foil, paper, and other thin-film materials. There are dry-type laminating machine, extrusion laminating machine, coating laminating machine, hot laminating machine, heat preservation material machine and others.

JIANGNAN LIGHT INDUSTRY MACHINERY COMPANY is a Chinese dry type laminating machine manufacturer and supplier. We offer dry type laminating machine, and automatic photo controlled cutting machine, film blowing and printing machine. Our high quality products are offered at competitive prices. JIANGNAN LIGHT INDUSTRY MACHINERY COMPANY is located in China, and the full chain of manufacturing automatic bag making machine, asepsis liquid filling machine can be completed in China, even in one city. Lower manufacturing cost saves your purchasing cost. The more details of each product are shown on the page with description.

Links:https://www.globefindpro.com/products/109052.html

-

Travel Product Packaging Paper Coating Laminating Machine

Travel Product Packaging Paper Coating Laminating Machine

-

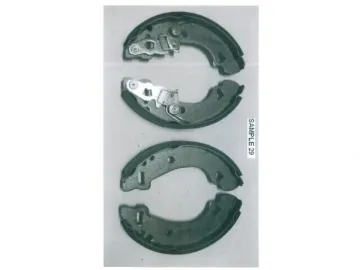

Brake Shoe

Brake Shoe

-

Chery

Chery

-

FAW

FAW

-

Low Metallic Brake Pads

Low Metallic Brake Pads

-

Intelligent Flake Ice Machine

Intelligent Flake Ice Machine

-

Non-Woven Coating Laminating Machine

Non-Woven Coating Laminating Machine

-

SL-45-600 Film Blowing Machine (Rotary Die)

SL-45-600 Film Blowing Machine (Rotary Die)

-

JSY-350 Film Blowing and Printing Machine

JSY-350 Film Blowing and Printing Machine

-

Paper and Plastic Coating Laminating Machine

Paper and Plastic Coating Laminating Machine

-

High Speed Paper and Plastic Coating Laminating Machine

High Speed Paper and Plastic Coating Laminating Machine

-

Printing and Coating Laminating Machine

Printing and Coating Laminating Machine