Basic Silica Gel

Basic Silica Gel

General Characteristics

Silica gel is a kind of highly active adsorption material. It is usuallyformulated by sodium silicate and sulphuric acidreaction and through a series of after treatment processes such as aging,pickling, etc. Silica gel is amorphous substance. Its chemical molecularformula is SiO2.nH2O. It is insoluble in water and any other solvent. It isnontoxic, non-odor and chemically stable. Except for alkali and hydrofluoricacid, it does not react with any other substance. Owing to their differentmanufacturing methods, silica gel can be formulated with different pore structures. Because of its unique chemicalcomposition and physical structure, silica gel possesses a great number of characteristics with whichother similar materials are incomparable, such as high adsorption feature,stable thermal performance, stable physical property and relatively highmechanical strength, etc.

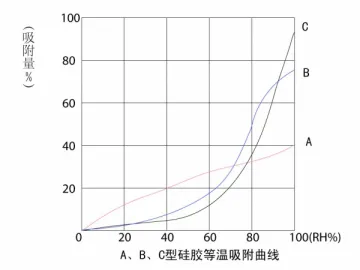

According to pore diameters, the silica gel can be classified into macro-pored,fine-pored and type B ones. The pore size of silica gel type B lies between macro-poredand fine-pored ones, and its adsorption capability is also between them. When there is a low relative humidity, fine-pored silica gel has a higher adsorptioncapacity than macro-pored one.Otherwise, macro-pored ones may have higher capacity. Largepored silica gel is usually used as catalyst carrier, matting agent andtoothpaste abrasive, etc. Therefore, the appropriate type is to be selectedaccording to your specific field of application.

SafetyPerformance

1. Themain component of silica gel is silica, which is chemically stable and flame resistant. Silicagel is a kind of non-crystalline silica. During manufacturing process, the dust content insidethe workshop should be no more than 10mg/m3, and the workshop should be well ventilated. Meanwhile, operatorsshould wear mouth-muffles.

2. The strong moistureadsorption capability of silica gel may cause drying of human skin. Therefore, operatorsshould be instructed to wear working clothes while processing. If silica gelaccidentally comes into one's eyes, be sure to wash them using a large amountof clean waterand seek for medical care as soon as possible.

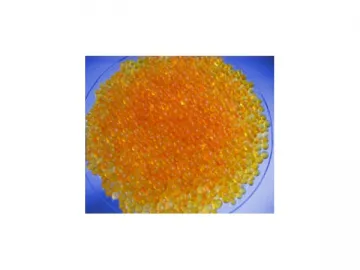

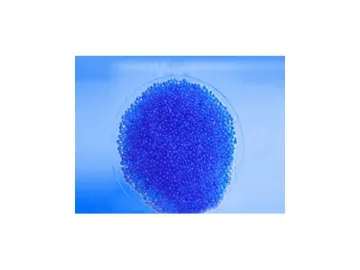

3. Containing small amount of cobalt chloride and being toxic,blue and orange silica gel should be kept from contacting the foods andinhaling into one's mouth. Seek for medical care as soon as possible once thereis a poisoning accident.

4. Colloidal silica or silica sol’s main composition is silicondioxide and water. It is also non-toxic.However, itsmain application is not absorption.

Reclamation

Since silica gel adsorbs steams and other organic substancesfrom the media, so itsadsorption capability declines. After being reclaimed, it can be used again.

1. The reclaim of silica gel after steam adsorption

After adsorbing moistures, the moistures contained in silica gel can be removed by heating. There are many methods for heating, for example,by electrically heated stove, remaining heat in the flue and hot air drying,etc.

For heating de-adsorption, the temperature should becontrolled to be within the range of 120-180℃. For blue gel indicator, chromotropic silica gel and blue silica gel DL, thetemperature should be controlled to be within 100-120℃.

When reclaiming industrial silica gels, please make sure the highesttemperatures are within the following limits:

Macro-pored silica gel no more than 600℃

Fine-pored silica gel no more than 200℃

Blue silica gel and orange silica gel (or chromotropic silica gel) no more than 120℃

Silica alumina gel no more than 350℃

The reclaimed silica gel can be put into use again as longas its moisture content is controlled to be less than 2%.

2. The reclamation after organic impurities adsorption

(1) Roasting

Put macro-pored silica gel into a roaster and gradually rise its temperature to500-6℃. After about 6-8 hours, the gelgrains become white or yellowish-brown. For fine-pored silica gel, the roastingtemperature shall be not more than 200℃.

(2) Bleaching

Put silica gel into saturated steam to adsorb until it is fully saturated, andthen drop it into hot water to soak and bleach. Detergent can also be used toremove the waste oil and other organic impurities. After washing it in cleanwater, dry it to remove the moistures.

(3) Solvent Rinsing

Depending on theorganic substances adsorbed by silica gel, select the appropriate solvent todissolve the organic substances adsorbed inside silica gel, then heat up silicagel to get rid of the solvent.

Points for Attentionin Silica Gel Reclamation

1. Gradually rise up the temperature during heating process toprevent the gel grains from exploding and thereby from reducing the recoveryratio as a result of severe drying.

2. In roasting reclaim, excessively high temperature may cause changes to thepore structure of silica gel, thereby substantially reducing its adsorptioneffect and affecting its usefulness. For blue gel indicator or discoloringsilica gel, the temperature for de-adsorption shall be not more than 120℃, otherwise, its developing agentwill be gradually oxidized and therefore lose its developing effect.

3. The reclaimed silica gel shall usually be sifted out to get rid of the finegrains, thus making the grains well-distributed and uniform.

Storage and Packing

Silica gel is strong in moisture adsorption; therefore, it should be stored indry places. Shelf racks should be put between the container and the floor. Thecontainers can be steel drums, paper bags, cardboard boxes, plastic bottles,polyethylene plastic compound bags and flexible container bags, etc. Pleaserefer to the categorized product descriptions for detailed packingspecifications.

All silica gel products should be kept from rain, moisture and sun.

The colloidal silica or silica sol should be kept between 0-40℃.

Sinchem is a China basic silica gel manufacturerand supplier. We offer basic silica gel, and cat litter, drying indicatorsilica gel. Our high quality products are offered at competitive prices. Sinchem is located in China,and the full chain of manufacturing tiny power silica gel, silicide can be completed in China,even in one city. Lower manufacturing cost saves your purchasing cost. The moredetails of each product are shown on the page with description.

Links:https://www.globefindpro.com/products/109521.html

-

Narrow Pored Silica Gel (Type A)

Narrow Pored Silica Gel (Type A)

-

Plastic Open Agent

Plastic Open Agent

-

Cat Litter

Cat Litter

-

Oil Detergent

Oil Detergent

-

Orange Indicator Silica Gel (Turn Orange into Dark Green)

Orange Indicator Silica Gel (Turn Orange into Dark Green)

-

Silica Gel Desiccant

Silica Gel Desiccant

-

Colorful Cat Litter (Bead)

Colorful Cat Litter (Bead)

-

Wide Pore Micro Spherical Silica Gel

Wide Pore Micro Spherical Silica Gel

-

Big Wide Pore Silica Gel

Big Wide Pore Silica Gel

-

Container Use Silica Gel

Container Use Silica Gel

-

Silica Gel Type B

Silica Gel Type B

-

Blue Indicator Silica Gel (Turn Blue into Pink)

Blue Indicator Silica Gel (Turn Blue into Pink)