Roll Forming Machine JCH-760

Roll Forming Machine JCH-760

The JCH-760 roll formingmachine is used applied in roofing and construction. This roll forming machine features highefficiency and simple operation. It iswell received by customers from Canada,South Korea, Russia, and Malaysia, to name a few.

Production Process

Our JCH-760 roll forming machine completes thewhole production process starting from planning until the finished productarrives. We begin with decoiling thesteel plates and feeding the raw steel material into the machine. Next, the rolling forming begins byaccurately processing the length measurement of the product and cutting itaccordingly. The process finishes byputting out the roll formed steel plate.

Main Machine Components

The JCH-760 roll forming machine consists of many componentsincluding a decoiler, forming machine, hydraulic cutter, electric controllingsystem (PLC), hydraulic system and product stand.

Technical Specifications

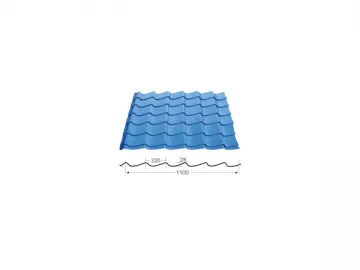

Profile

Thickness: 0.3-0.8mm

Inner Tight Decoiler

Coil inner diameter: 450-700mm

Max. width of coiling: 1250mm

Max. loading capacity: 5000kg

Main Forming Machine

Shafter material: 45# steel

Shafterouter diameter: 100mm

Bearing steel outer diameter: 85mm

Rollermaterial: 45# steel

Main motor power: 7.5kW

Operating speed: 8-10m/min

Voltage supply: 380V, 50Hz

Roller station: 22

Cutting System

The cutting system features a hydraulic cutter with blade andmold material made from Cr12 steel with quenched treated 60-62.

Control System

The electronic controlling system is TAIDA, which we import from Taiwan and the coder is imported from South Korea.

HydraulicSystem

The advanced hydraulic system from Taiwan requiresa power supply of 3kW

Spare Parts

The JCH-760 roll formingmachine includes the following spare parts: 2 pieces of conk, 4 pieces of fuse-link, 1 rubber mat, and 1 boltspanner.

EquipmentMaintenance

Maintenance of our roll forming machine is quite easy. We recommend that you regularly feedlubricant to the machine gear, chain and moving parts to reduce friction andavoid rusting. Make sure the power linesare properly connected before starting the machine and a regular intervals,change the gear oil and hydraulic oil.

Packaging

Our roll forming machine is wrapped in a waterproof package.

Service

1. We provide a one year warranty and lifelong technical support.

2. We can send our technicians to you to give you on-site training. The training period would be for no more thanone week with the customer paying for the visa, return ticket, food,accommodations and a daily wage of US50.

3. We provide a user’s manual and installingsketch map.

FEIXIANG is a specialized roll forming machine manufacturer and supplier, based in China. Our mainproducts include C purlin roll forming machines, auto crimping curved rollforming machines, corrugated sheet roll forming machines, etc. Our machines are manufactured in strictaccordance with the ISO9001:2000 standard. Due to their excellent performance and reasonable prices, our machinesare well received by customers worldwide. If you have any related product need, please feel free to contact us viaany of the contact methods listed on our website.

Links:https://www.globefindpro.com/products/109833.html

-

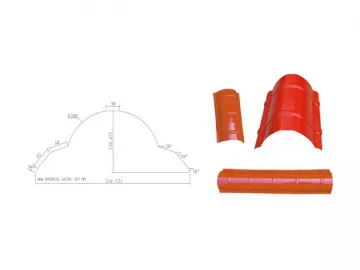

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine

-

Punching Machine

Punching Machine

-

Wall Panel Roll Forming Machine FX900

Wall Panel Roll Forming Machine FX900

-

Roof Panel Roll Forming Machine FX840

Roof Panel Roll Forming Machine FX840

-

Arc Bias Glazed Tile Roll Forming Machine FX1100

Arc Bias Glazed Tile Roll Forming Machine FX1100

-

Light Keel Roll Forming Machine

Light Keel Roll Forming Machine

-

Furring Channel Roll Forming Machine

Furring Channel Roll Forming Machine

-

Glazed Tile Roll Forming Machine FX1000

Glazed Tile Roll Forming Machine FX1000

-

C Purlin Roll Forming Machine

C Purlin Roll Forming Machine

-

Two Wave Highway Guardrail Roll Forming Machine

Two Wave Highway Guardrail Roll Forming Machine

-

Glazed Tile Roll Forming Machine FX828

Glazed Tile Roll Forming Machine FX828

-

DIN 3352 F5-G5CT G5HT-TT Gate Valve

DIN 3352 F5-G5CT G5HT-TT Gate Valve