Auto-Checking Blister Machine (DPB-250B-I)

Auto-Checking Blister Machine(DPB-250B-I)

Theauto-checking blister machineis the latest generation product in our company. The auto-checking blister machine uses PLCHuman Interface, with frequency converter. It features high automation, easy operation, novel figure,all-round-functions, advanced technology, stable running, durable life, and conformsto the "GMP Standard". Theauto-checking blister machine is ideal for AL/PL, AL/AL, Paper/PL packaging. It has passed Province technology productionauthentication.

Features

1. The auto-checkingblister machine is equipped with an inductive self-checking mechanism which caneliminate the waste plate with lack of particle, making sure the qualified ratereaches 100%. (Optional)

2. The heat sealing station of the auto-checking blister machine isfixed and the distances between parts for forming, perforation, punching, etc.can be freely adjusted on the same plane. With high precision and strong adaptability, the auto-checking blister machine is perfect for packing plateswith all kinds of dimensions.

3. With its flat structure, the auto-checking blister machine has lots of functions, includingimage and character register heating, positive forming,aircushion heating-sealand checkeredplates, and adjustablestroke. It is very convenient to operate.

4. Main transmission of the auto-checking blister machine uses an imported gearreducer, which features excellent performance, low noise, long life and stableoperation.

5. The cursor tracks register, sealing neatly and making a good-lookingappearance. The body of theauto-checking blister machine can be manufactured separately for easy transportinto workshop. (Optional)

6. The auto-checking blister machine can be equipped with an optical fiber or photographing checking deviceaccording to the customers' requirements.

Main Technical Parameters

| Cutting Frequency (times/min) | AL/AL 6-25, Al/plastic paper/plastic 6-35 |

| Capacity (10 thousand pcs/h) | Al-Al≤11 Al-plastic≤23 |

| Max. Forming Area and Depth (mm) | AL/AL:240×150×9 AL/PL: 240×150×26 |

| Stroke (mm) | 40-160 can be manufactured as user's requirements |

| Standard Plate (mm) | 80×57 can be manufactured as user's requirements |

| Air Pressure (Mpa) | 0.4-0.6 |

| Air Supply | ≥0.3 m³/min |

| Total Power | 380V/220V 50Hz 6.2kw |

| Main Motor Power (kw) | 1.5 |

| Forming Aluminum (mm) | 0.085-0.1×250 |

| Pvc Hard Pieces (mm) | 0.15-0.5×250 |

| Ptp Aluminum Foil (mm) | 0.02-0.035×250 |

| Dialysis Paper (mm) | 50-100g×250 |

| Mold Cooling | Tap water or recycling water |

| Overall Dimensions (mm) | 2710×720×1600(L×W×H) |

| Weight (kg) | 1600 |

Antai is an auto-checking blister machine manufacturer, based in China. We offer auto-checking blister machines, servoblister packing machines, automatic capsule filling machines, etc. We provide high quality products atcompetitive prices. Our company canprovide the full chain of manufacturing jam blister machines and automaticplastic packaging machines right here in China. Our lower manufacturing cost saves yourpurchasing cost. More details on each ofour products are shown on the description page.

Links:https://www.globefindpro.com/products/110178.html

-

Auto-Checking Blister Machine (DPB-140B-I)

Auto-Checking Blister Machine (DPB-140B-I)

-

Flat Plate Blister Packing Machine (DPB-250E-I)

Flat Plate Blister Packing Machine (DPB-250E-I)

-

Cosmetics Packaging Machine DPB-250 (Crystal Facial Mask)

Cosmetics Packaging Machine DPB-250 (Crystal Facial Mask)

-

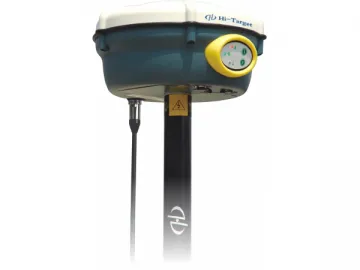

HD8200X Static GPS

HD8200X Static GPS

-

V9 GNSS RTK System

V9 GNSS RTK System

-

V30-S Integrated Intelligent Static GPS

V30-S Integrated Intelligent Static GPS

-

Automatic Cartoning Machine ANTZ-120

Automatic Cartoning Machine ANTZ-120

-

Drill Pipe

Drill Pipe

-

Architectural Decoration, Supermarket Shelves, Cabinets Tube

Architectural Decoration, Supermarket Shelves, Cabinets Tube

-

Fluid Delivery Pipe

Fluid Delivery Pipe

-

Automobile Pipe

Automobile Pipe

-

Pipe Pup Joint

Pipe Pup Joint