Corrugated Sheet Forming Machine

CorrugatedSheet Forming Machine

Withthe development of technology for producing light steel structures, corrugatedsheet is growing in popularity for use in low-rise buildings. Many corrugated sheetsare used for building roofs, decking for the fences, etc. Our corrugated sheet forming machine producesbeautiful, elegant and noble corrugated sheet, which is widely used ingarden-style factories, scenic travel spots, hotels, exhibition centers, villas,civil construction and so on.

Main Equipment

Our corrugated sheet forming machine consists of amanual decoiler, feeding platform, main molding core, shearing machine,hydraulic station, computer control cabinet, and high precision counter, and drivensystem protective covering panel supporting table.

Flow Chart

Decoiling the sheet---Guiding the sheet---Roll forming---Measuring thelength---Cutting the sheet---on the output table

Machine Components

| Guiding Table | 1 set |

| Manual Decoiler | 1 set |

| Main Forming Machine | 1 set |

| PLC Control System | 1 set |

| Hydraulic Cutting Station | 1 set |

| Output Table | 1 set |

Technical Specifications

| Item | Description |

| Material Width | 914mm-1250mm |

| Material Thickness | 0.14mm-0.6mm |

| Material | PPGI HDGI |

| Yield Stress | 235-330Mpa |

| Material of Roller | 45# steel plant hard chromium 0.05mm |

| Diameter of Shaft | 70-80mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5-7.5kw |

| Hydraulic Power | 4kw |

| Stand | 11-22 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

Machine Placement and Operator

The corrugated sheet forming machine should be placed on an even cementfloor and lifted by a lifting device with a lifting capacity not less than fivetons. It requires space for storingmaterials and laying the machine and room to operate the machine. In addition, the forming machine requires oneoperator and one porter. The temperaturein the workspace should be no less than -14℃.

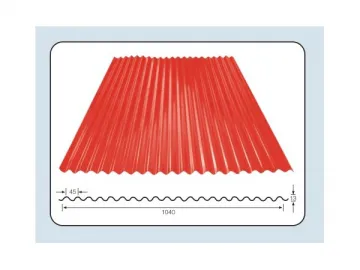

Technical Specifications 13-45-1040

| Item | Description |

| Material Width | 1200mm |

| Material Thickness | 0.3mm-0.8mm |

| Material | PPGI HDGI |

| Yield Stress | 235Mpa |

| Material of Roller | 45# steel plant hard chromium 0.05mm |

| Diameter of Shaft | 75mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5kw |

| Hydraulic Power | 4kw |

| Stand | 17 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

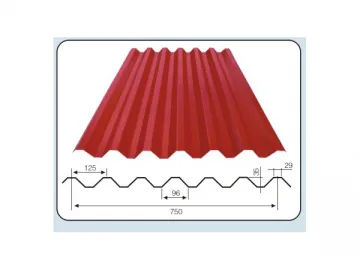

TechnicalSpecifications YX18-76-1064

| Item | Description |

| Material Width | 1000mm |

| Material Thickness | 0.3mm-0.8mm |

| Material | PPGI HDGI |

| Yield Stress | 235-330Mpa |

| Material of Roller | 45# steel plant hard chromium 0.05mm |

| Diameter of Shaft | 70mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 5.5kw |

| Hydraulic Power | 4kw |

| Stand | 22 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-15m/min |

| Decoiler | 5 tons manual or hydraulic |

Haide is a China-based corrugated sheet forming machine manufacturer,specializing in a great variety of roll forming machines. Our popular products include sandwich panelproduction lines, tile forming machines, wall panel forming machines, andmore. As a result of their high qualityand low prices, our products are sought after by customers in many countries,including Chile, Bolivia, Thailand,Armenia, Uzbekistan, Cameroon,Russia, Saudi Arabia, and Turkmenistan. Our company is located in Botou City where we have convenient access to many kinds of transportation. Our location facilitates the transport of ourlighting products and greatly reduces the freight charges for our customers.

We look forward to working with customers all over the globe.

Links:https://www.globefindpro.com/products/110551.html

-

Wall Panel Forming Machine

Wall Panel Forming Machine

-

T10 LED Fluorescent Tube, YK-B1020J

T10 LED Fluorescent Tube, YK-B1020J

-

Die Board Laser Cutting Machine, 200-300W

Die Board Laser Cutting Machine, 200-300W

-

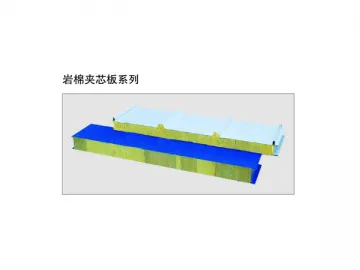

Sandwich Panel Production Line

Sandwich Panel Production Line

-

Roof Panel Forming Machine

Roof Panel Forming Machine

-

Laser Cutting Machine, 700-1500W

Laser Cutting Machine, 700-1500W

-

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094

T5 LED Fluorescent Tube, YK-B1091, YK-B1092, YK-B1093, YK-B1094

-

Abrasive Cutting Machine

Abrasive Cutting Machine

-

T10 LED Fluorescent Tube, YK-B1034

T10 LED Fluorescent Tube, YK-B1034

-

T10 LED Fluorescent Tube, YK-B1031J, YK-B1032J, YK-B1033J

T10 LED Fluorescent Tube, YK-B1031J, YK-B1032J, YK-B1033J

-

Impact Machine

Impact Machine

-

Double Layer Forming Machine

Double Layer Forming Machine